Multi-station concrete component forming machine

A concrete and molding machine technology, applied in ceramic molding machines, molding indenters, manufacturing tools, etc., can solve the problems affecting the strength and shape of concrete components, the components are prone to honeycomb pits, and the service life of equipment is shortened, and achieves high rigidity. , Not easy to deform or tilt, improve strength and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

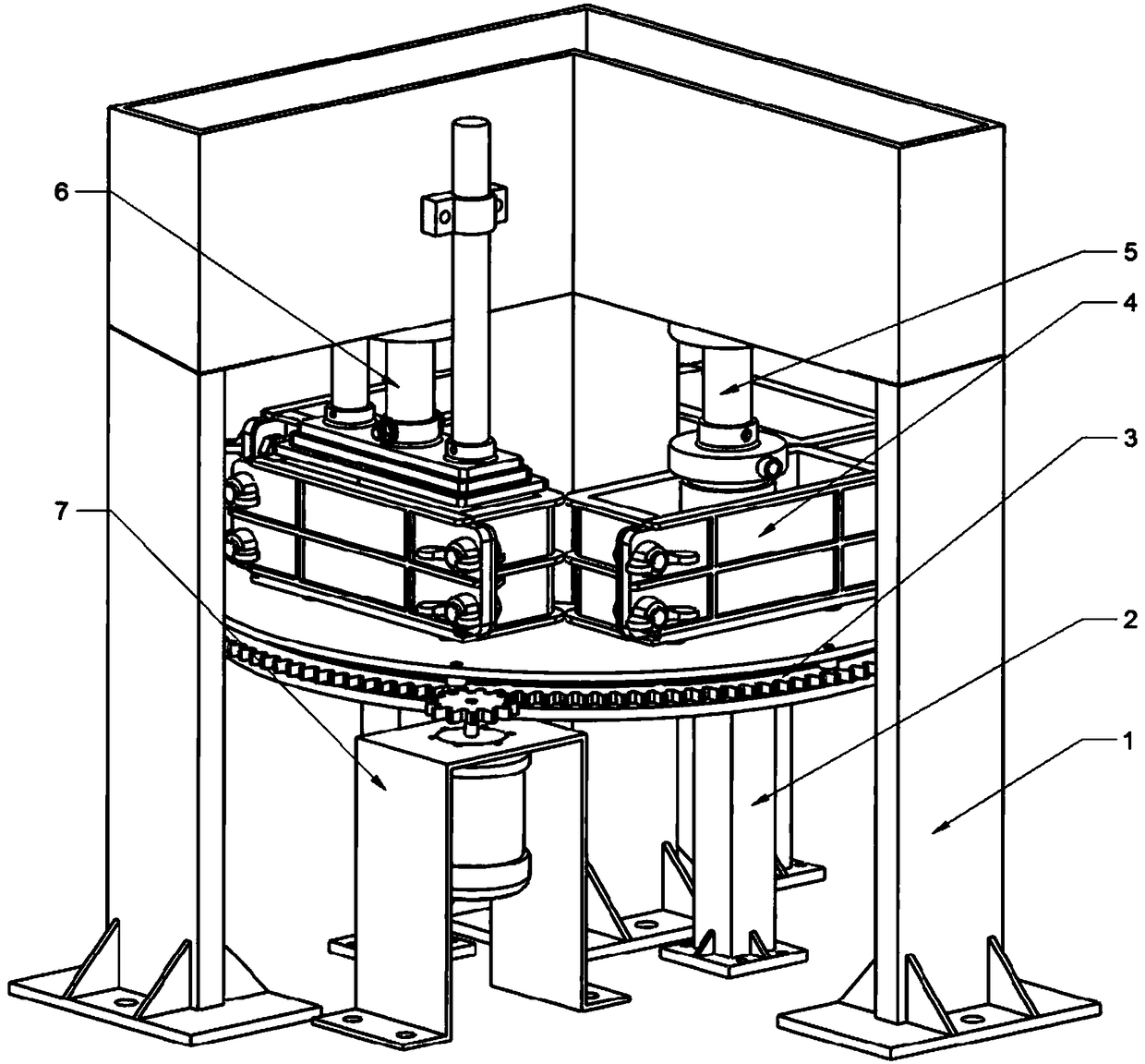

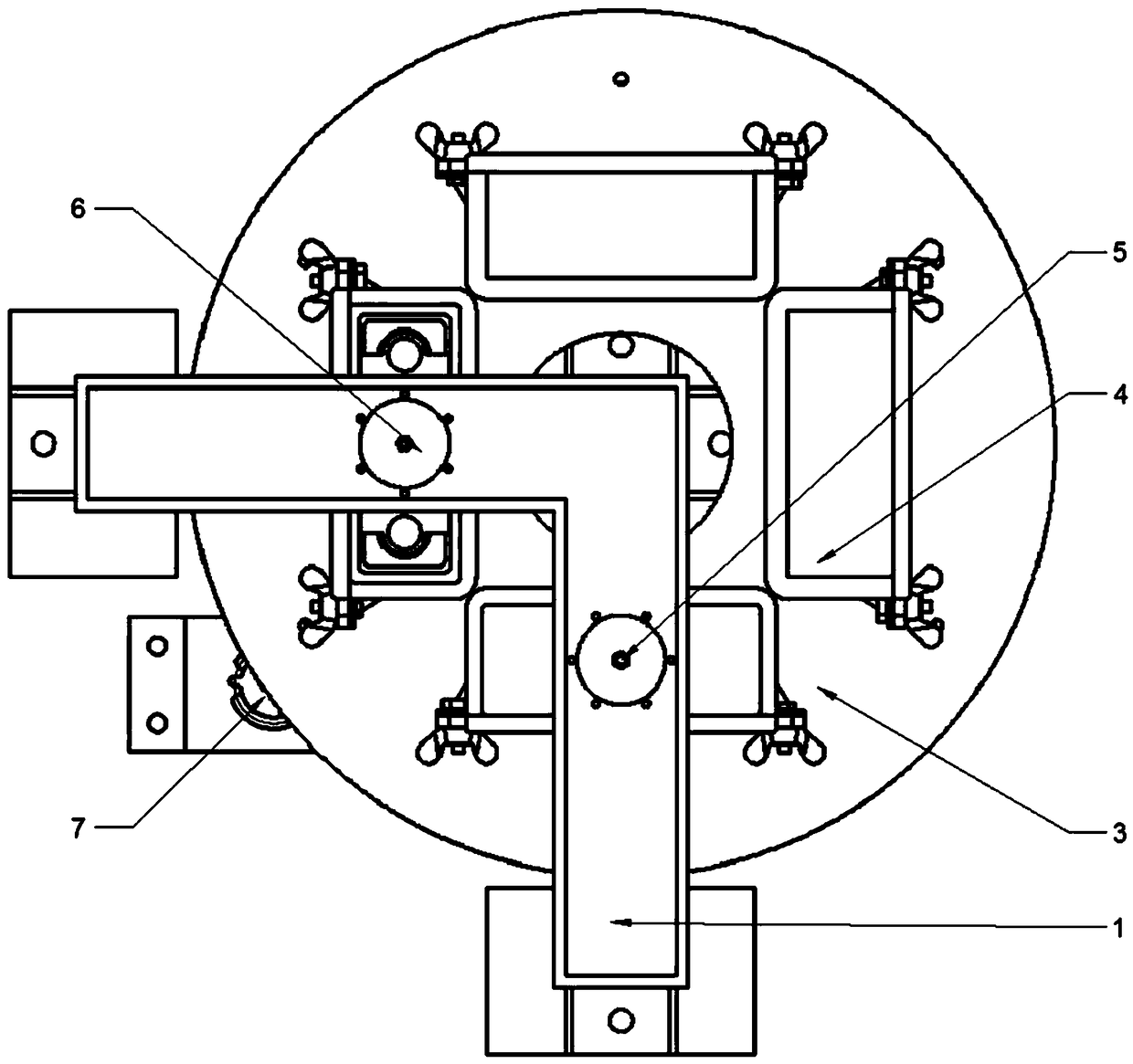

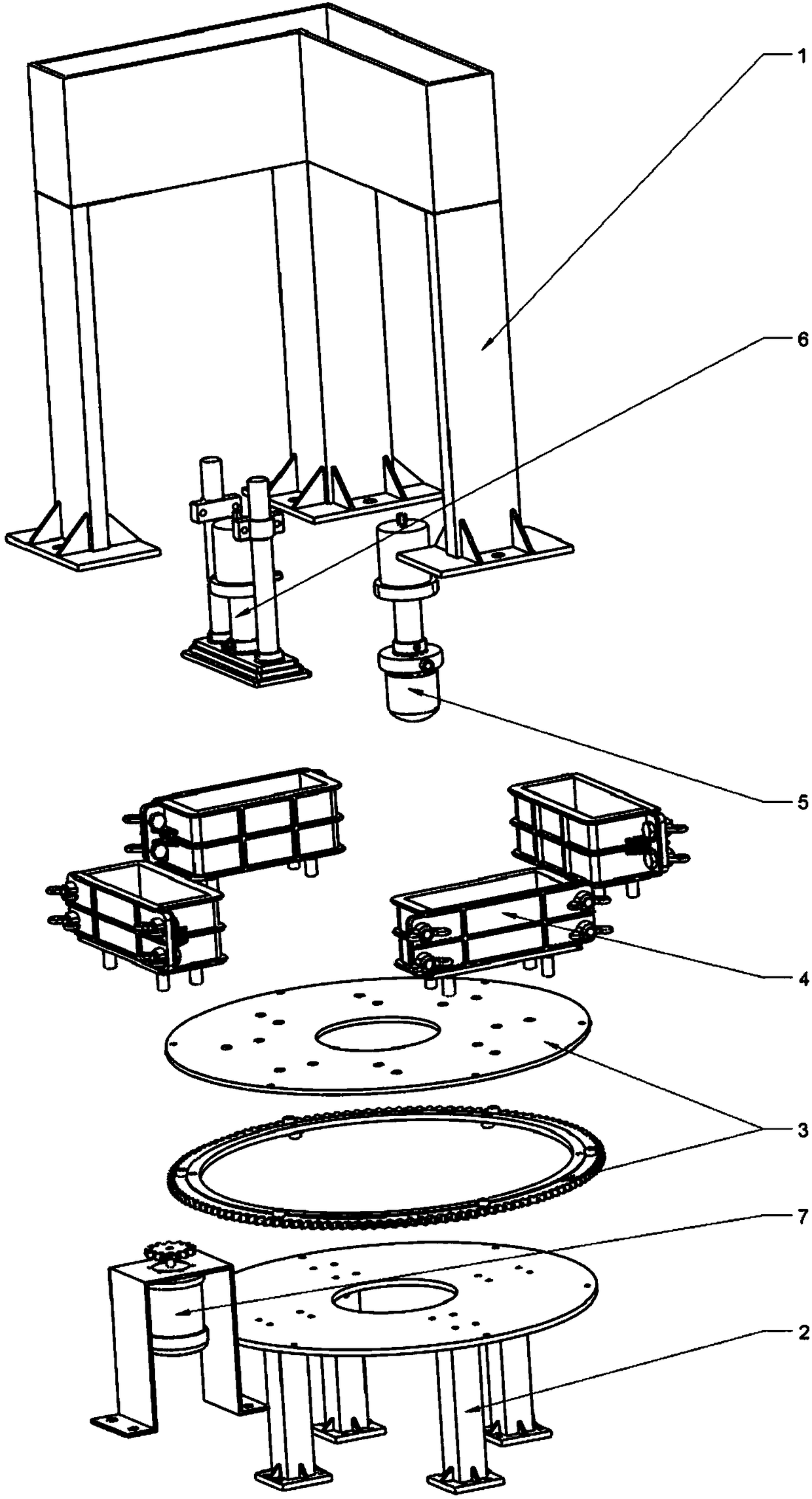

[0036] The present invention will be further described below in conjunction with accompanying drawing:

[0037] Such as Figures 1 to 11 As shown, the multi-station concrete component forming machine of the present invention includes a drive assembly 7 and a door frame 1, and the door frame 1 includes a tank box 1.3, and a vibrating assembly 5 and an extrusion assembly 6 are installed on the tank box 1.3; The bottom surface of the box 1.3 is equipped with a central column 1.2 and a side column 1.1 to form a double gantry structure. The lower ends of the central column 1.2 and the side column 1.1 are fixed on the ground or the foundation floor. The gantry structure has better stability and greater rigidity. It is not easy to deform or tilt during use, avoiding the inclination and insufficient pressure of the mold head 6.1 due to the deformation of the frame in the extrusion process, so that the concrete components are evenly stressed, and the produced concrete components have u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com