A kind of antifreeze concrete and its processing method and application

A processing method and concrete technology, applied in the field of concrete, can solve problems such as inability to process bagged concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

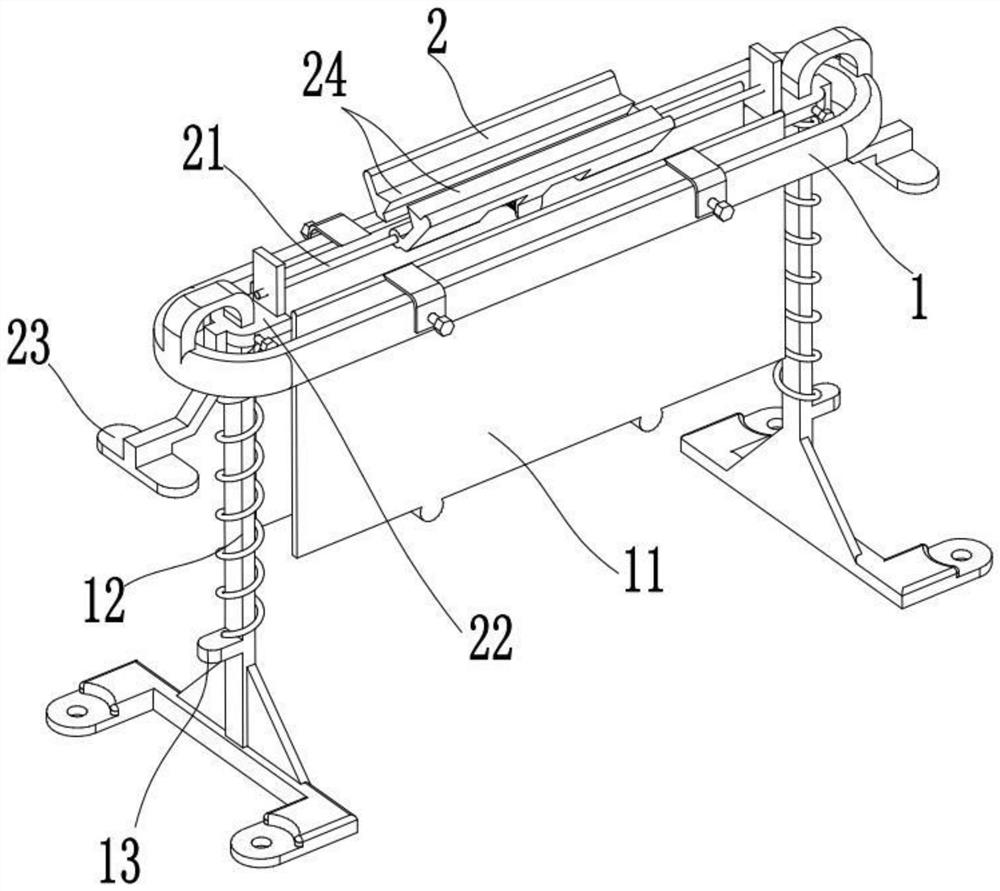

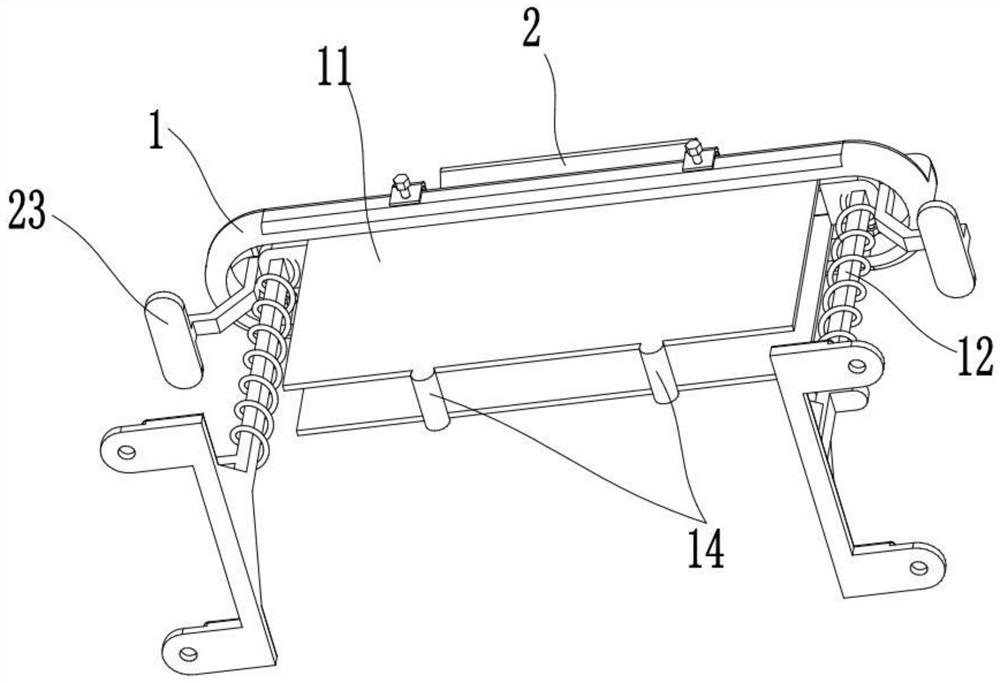

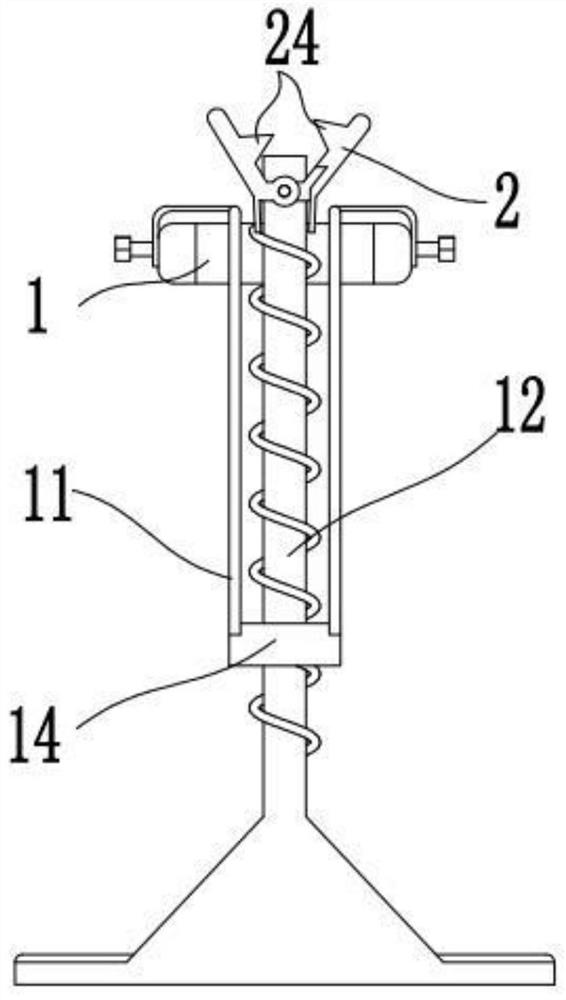

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0035] A method for processing frost-resistant concrete, the method comprising the following steps:

[0036] a: mixing and stirring the raw materials used for preparing antifreeze concrete to prepare antifreeze concrete;

[0037] b: Fix the bottom of the sack for containing concrete;

[0038] c: Put the concrete into the sack and adjust the shape of the sack containing the concrete;

[0039] d: After the concrete is formed, take out a sack with concrete in a certain shape.

[0040] A kind of frost-resistant concrete, which is composed of the following raw materials in parts and weights: 50 parts of coarse aggregate, 40 parts of fine aggregate, 15 parts of cement, 15 parts of water and 2 parts of freeze-thaw resistant modified fiber.

[0041] The invention relates to an application of the antifreeze concrete processed by the antifreeze concrete processing method, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com