A heat treatment method for adjusting the microstructure of nickel-based powder superalloy

A heat treatment method and high-temperature alloy technology, which are applied in heat treatment equipment, heat treatment process control, metal processing equipment, etc., can solve problems such as unfavorable alloy strength and coarsening of γ' phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

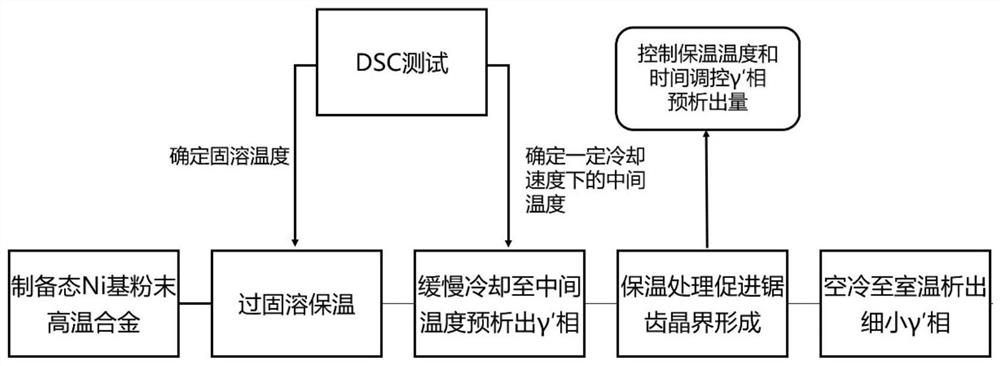

Method used

Image

Examples

Embodiment 1

[0042] Prepare alloy one: the composition is C 0.05, Cr12.7, Co20.4, Mo3.8, W2.1, Al3.5, Ti3.7, Ta2.4, Nb0.9, Zr0.045, B 0.02, Ni Amount of prepared nickel-based powder superalloy.

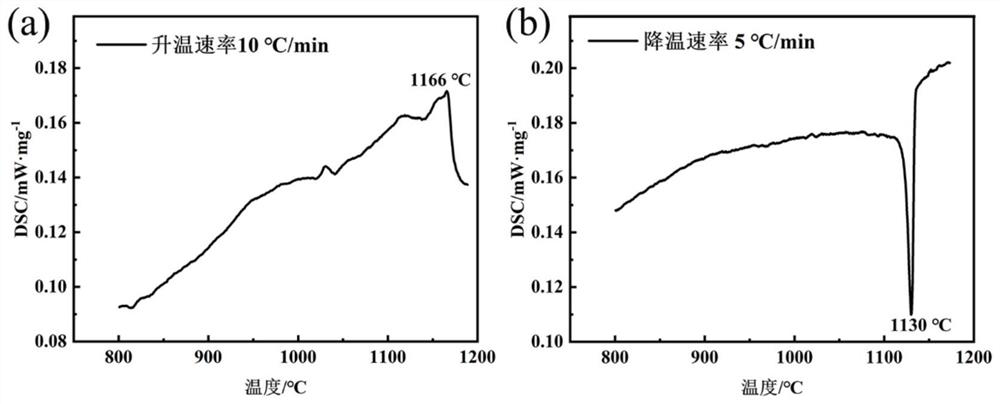

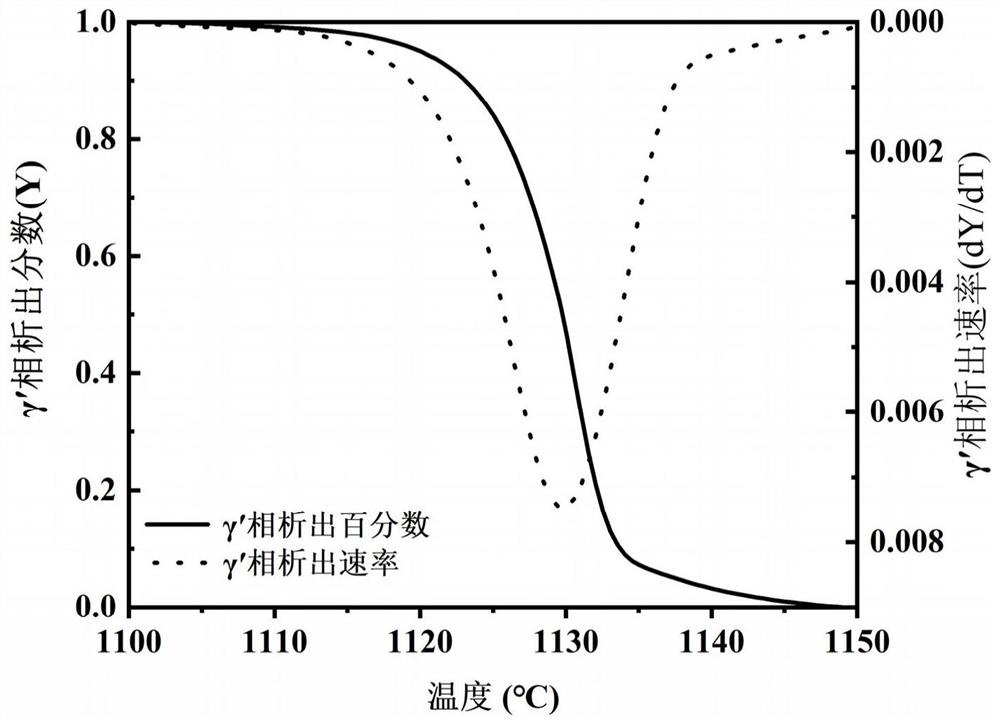

[0043] DSC analysis was carried out on Alloy 1, from figure 2 In the left figure (a), it can be seen that during the heating process, the endothermic peak gradually rises to the peak in a wide temperature range, and then quickly falls back to the baseline. The melting temperature of the γ′ phase in the as-prepared alloy was determined to be 1166°C as measured in the figure. figure 2 The figure on the right (b) is the DSC curve during the cooling process of the as-prepared alloy, and the cooling rate is 5°C / min. image 3 In order to calculate the γ′ phase precipitation percentage and phase transformation rate curve at different temperatures through DSC curve calculation. The heat treatment process selects the over-solution treatment temperature as 1190°C, and the over-solution holding time as ...

Embodiment 2

[0046]Select Alloy 1 as the raw material; the heat treatment process selects the over-solution treatment temperature as 1190°C, and the over-solution holding time as 2h; then slowly cools to 1140°C at a cooling rate of 5°C / min, so that about 5% of the The γ′ phase nucleates preferentially near the grain boundary, and the γ′ phase that nucleates preferentially grows up to promote the formation of the zigzag grain boundary after being kept for 60 minutes; finally, the fine γ′ phase is precipitated in the grain by air cooling.

[0047] The heat treatment parameters of Example 2 are shown in Table 1, and the sample grain boundaries and intragranular γ' phase morphology of alloy one after heat treatment are shown in Figure 5 , the grain boundary of the alloy is jagged, the amplitude of the zigzag grain boundary is 1.84 μm, and the average size of the intragranular γ′ phase is 30.4 nm, as shown in Table 2.

Embodiment 3

[0051] Prepare Alloy 2: Composition of C 0.05, Cr13.1, Co21.6, Mo4.0, W1.9, Al3.3, Ti3.4, Ta2.7, Nb0.8, Hf 0.5, Zr0.036, B 0.02 , Ni balance prepared nickel-based powder superalloy.

[0052] Carry out DSC analysis to alloy 2, from Figure 7 From the figure (a) on the left, it can be obtained that the dissolution temperature of the γ′ phase in alloy 2 is 1170°C. Figure 7 The right figure (b) is the DSC curve during the cooling process of alloy 2, and the cooling rate is 5°C / min. Figure 8 In order to calculate the γ′ phase precipitation percentage and phase transformation rate curve at different temperatures through DSC curve calculation. Select the over-solution treatment temperature as 1200°C, and the over-solution holding time as 1h; then slowly cool to 1110°C at a cooling rate of 5°C / min, so that about 70% of the γ′ phase is preferentially near the grain boundary during the slow cooling process. Nucleation, heat preservation for 10min to make the preferentially nucleate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com