Quickly-assembled sunken ceiling structure

A ceiling structure and ceiling technology, which is applied to building components, building structures, buildings, etc., can solve problems such as extended construction period and dirty construction site, and achieve the effect of convenient and fast construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

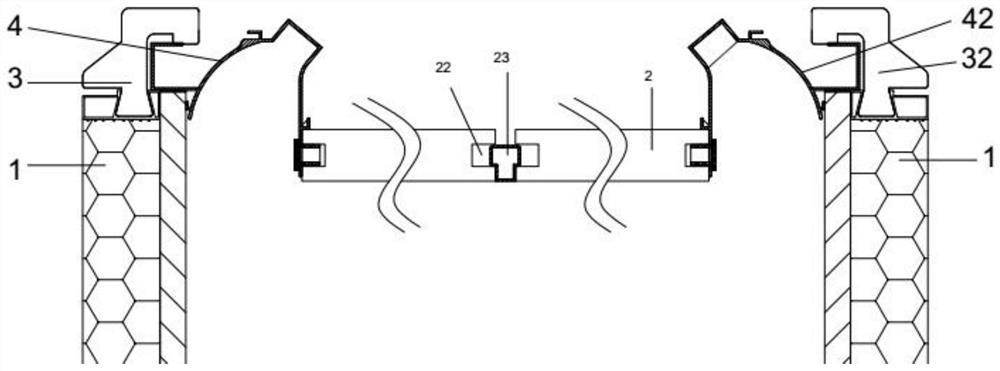

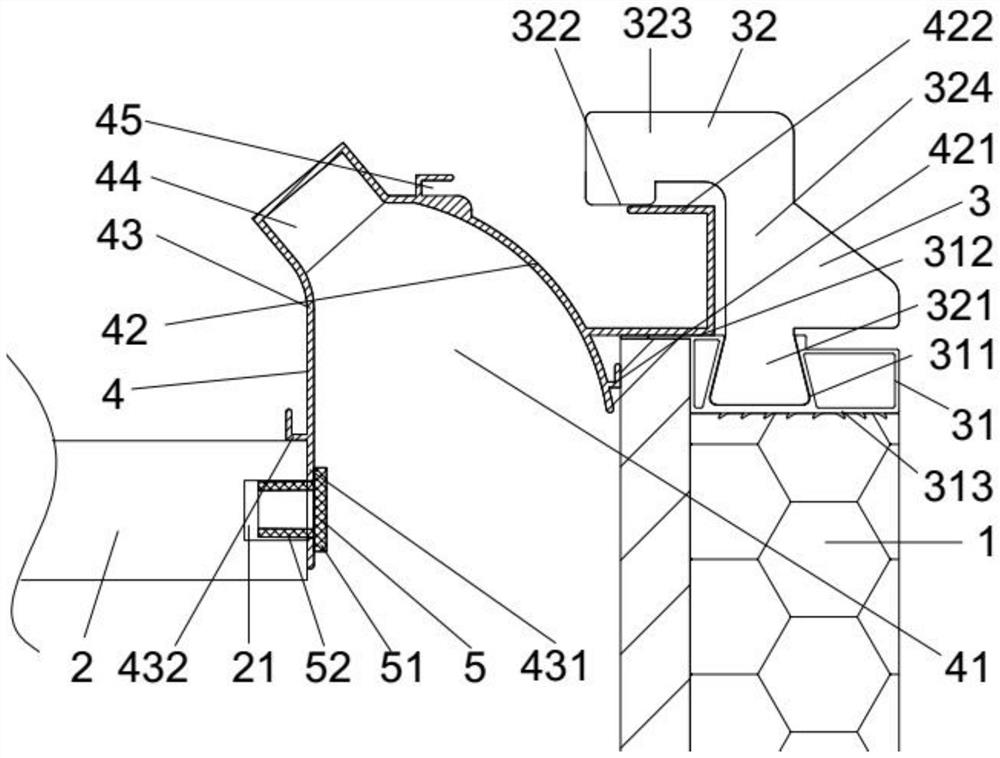

[0020] see Figure 1-Figure 2 As shown, the present invention discloses a quick-install sunken ceiling structure, which includes a connection assembly for connecting the wall panel 1 and the ceiling 2. The connection assembly includes 32 press buckles 3 and grooved parts 4. When assembling, the press buckle 32 The part 3 is installed on the upper end surface of the wallboard 1. The groove part 4 includes a groove body 41 with the opening downward. The groove body 41 includes a first side wall 42 and a second side wall 43. The outside of the first side wall 42 is provided with a The abutment plate 421 against the side wall of the wallboard 1 is provided with a crimping portion 422 above the top and bottom plate, and the 32 pieces of the crimping button 3 are provided with a mounting portion 313 for installing the 32 crimping pieces 3 on the wallboard 1 and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com