Spectrum identification method for high-temperature sterilized milk, pasteurized milk and pasteurized milk doped with high-temperature sterilized milk

A high-temperature sterilization and pasteurization technology, which is used in character and pattern recognition, material analysis by optical means, measurement devices, etc., can solve the problems of poor data mining results, huge data, inconsistency, etc. The effect of improving speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Establishment of the model

[0035] Apparatus and equipment: MilkoScanTM7RM milk component detector produced by FOSS Company was selected (operated according to the product instruction manual).

[0036] Specific steps are as follows:

[0037] (1) Collect milk samples

[0038]Commercially purchase different batches of pasteurized milk and high-temperature sterilized milk, mix all the high-temperature sterilized milk, and mix the high-temperature sterilized milk according to the volume percentage of 0%, 10%, 20%, 50%, and 100% respectively. Added to pasteurized milk, the numbers of the five adulterated fresh milks were 1, 2, 3, 4 and 5, and the sample numbers of the five adulterated fresh milks were 111, 110, 114, 113, 102, A total of 550 samples.

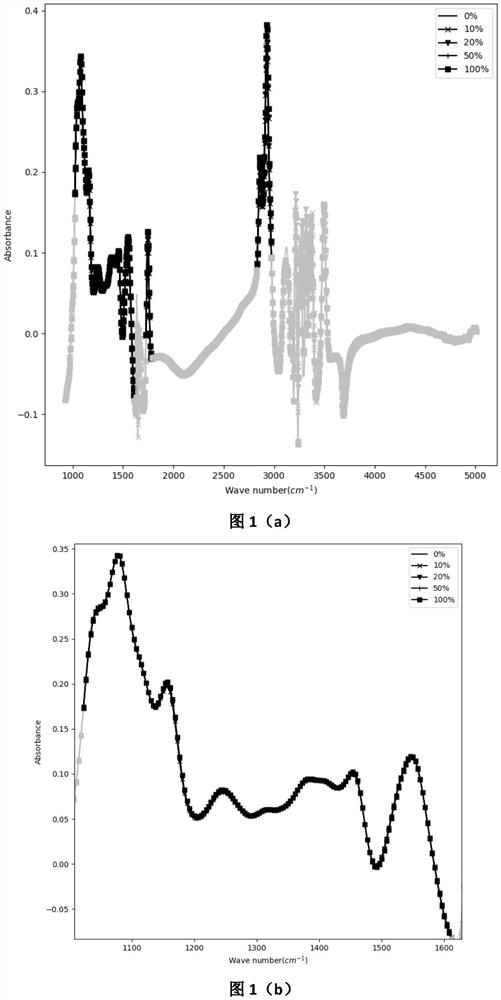

[0039] (2) Acquisition of mid-infrared spectra

[0040] Pour the milk samples into cylindrical sample tubes with a diameter of 3.5cm and a height of 9cm to ensure that the liquid level is greater than 6cm, then ...

Embodiment 2

[0060] Embodiment 2: the application of the model of the present invention

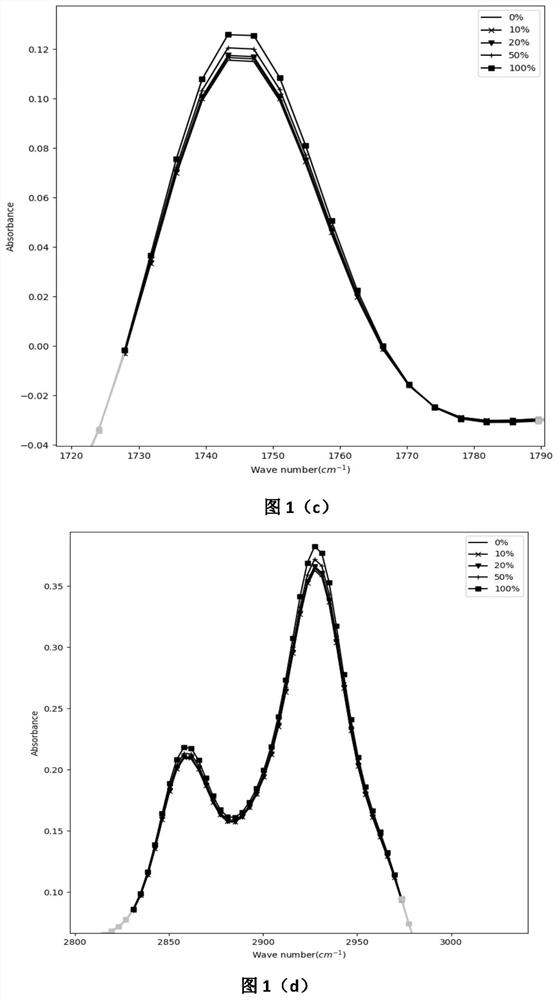

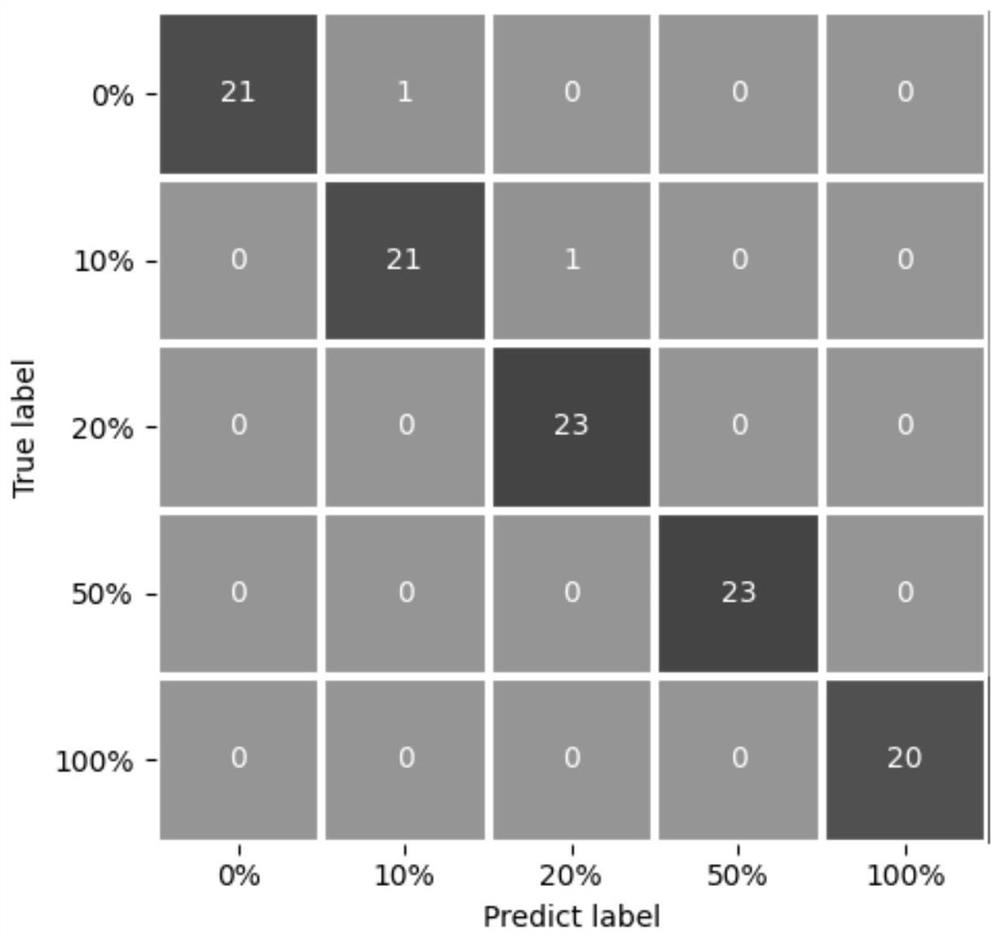

[0061] Using the technologies of measuring spectrum and data preprocessing in Example 1, 50 samples were measured and processed, and the optimal model selected was used for identification. The results are shown in Table 4.

[0062] Table 4 model application results

[0063]

[0064]

[0065] The present invention measures and processes 50 samples, and eliminates one abnormal value based on the Mahalanobis distance. Using the screened optimal model for identification, one misclassification was detected (category 2 was misjudged as category 3), and the remaining 48 samples were all classified correctly, with an overall accuracy rate of 0.98.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com