Special feed cylinder inspection robot for broadcast transmitting machine room

A broadcast transmitter and inspection robot technology, applied in the field of inspection robots, can solve problems such as normal inspection and inability to quickly locate fault points, and achieve the effects of clear terminal display, improved off-road performance, and strong anti-interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as in the scope of the invention.

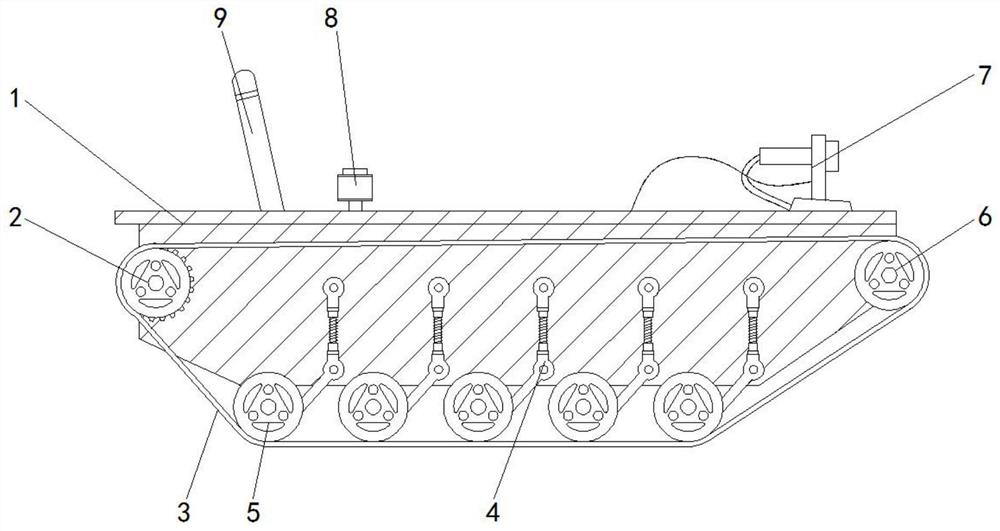

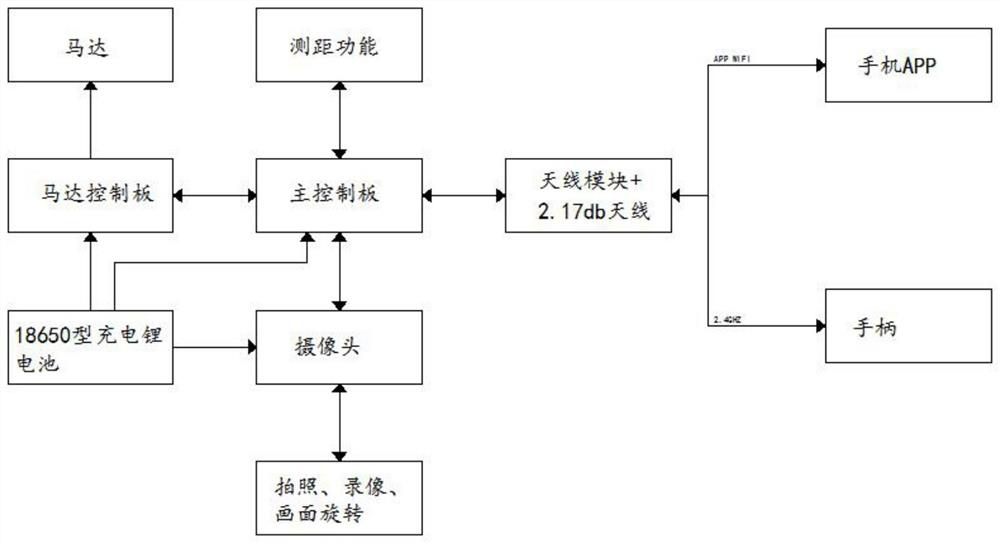

[0031] See Figure 1-2 A special feeder for a broadcast engine room in this embodiment includes a robotic body 1. The robotic body 1 is provided with a drive motor, and the motor output shaft is equipped with a drive wheel with a wheel tooth. The outer surface of the wheel 2 has a track 3, and the outer surface of the front and rear side of the robot body 1 is fixed, and the spring suspension shock absorber frame is fixed, the spring-type suspension shock absorber 4 external activity is connected to the track 5, the robot body, the robot body 1 One end of the front and rear side is equipped with a pulley 6 with the track 3, and the robotic body 1 is provided with an imaging mechanism 7, a switching mechanism 8, and an antenna mechanism 9.

[0032] The camera 7 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com