Double-drive steam turbine rotor stress monitoring method

A steam turbine rotor and stress monitoring technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as large errors, inability to obtain accurate stress values, and low calculation accuracy, so as to prolong rotor life and shorten start-up. Stop time, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

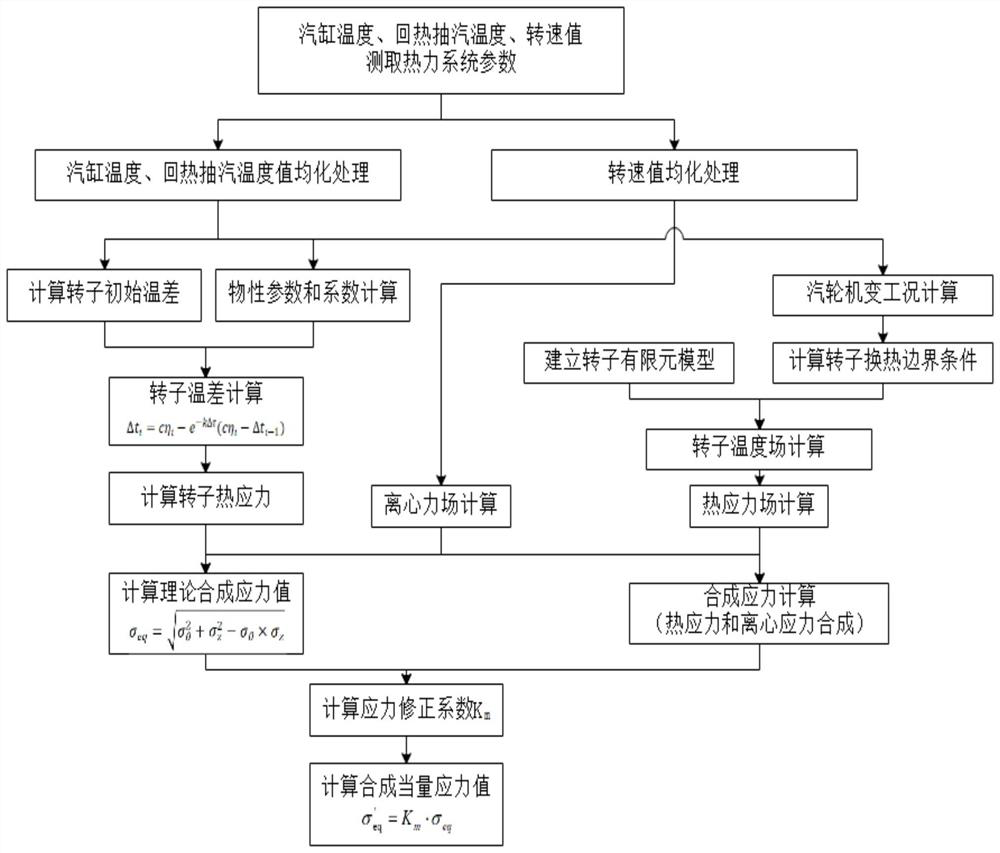

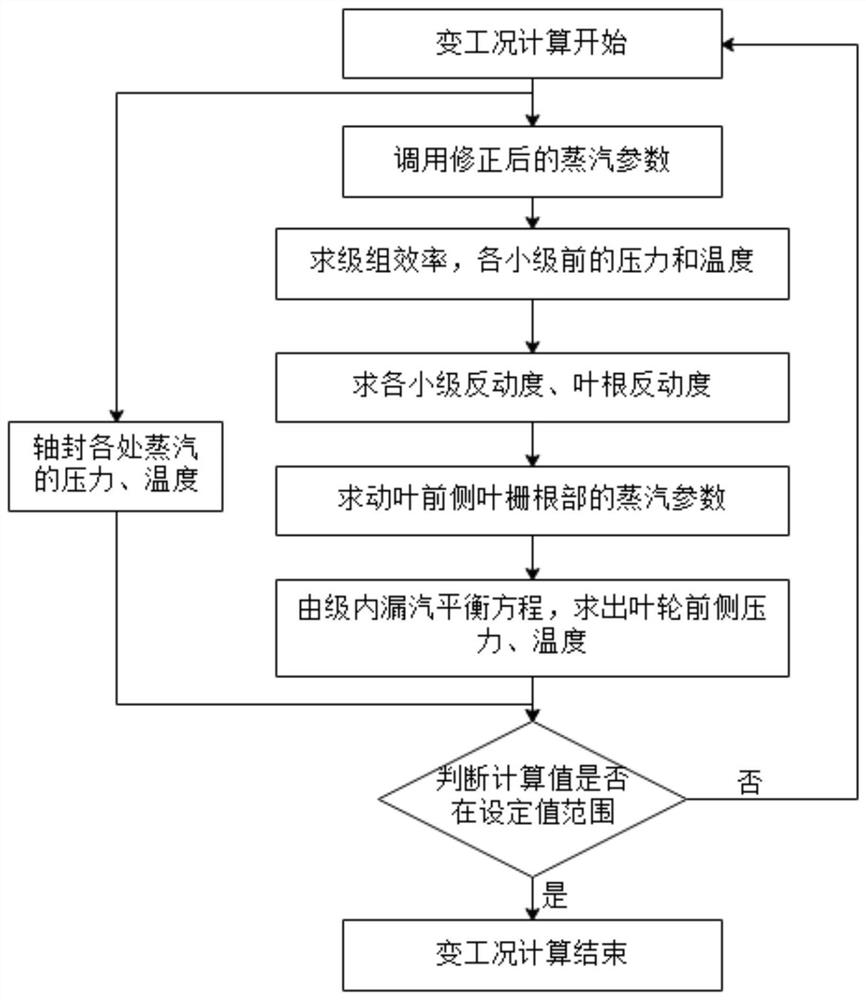

[0075] A dual-drive steam turbine rotor stress monitoring method, comprising the following steps:

[0076] S100. Real-time data acquisition: set the measuring points of the steam turbine, and obtain the steam parameters of each measuring point during the operation of the steam turbine in real time;

[0077] Considering the real-time fluctuation of the measured data during the operation of the unit, in order to obtain more accurate real-time measured data, the steam value obtained at each measuring point is preprocessed in this embodiment.

[0078] Specifically, the steam parameters in the step S100 include cylinder temperature values and regenerative extraction steam temperature values, and data preprocessing is performed on the cylinder temperature values and regenerative extraction steam temperature values obtained at different times for each measuring point:

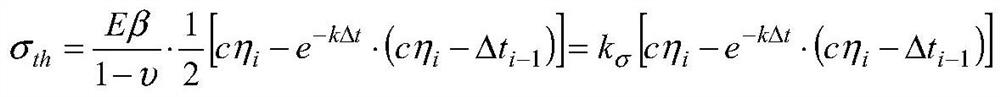

[0079] First, select n time points t for each measuring point i , t i+1 ,...,t n-1 , t n The correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com