Method, system and device for monitoring harvest yield of combine harvester

A technology of combine harvester and monitoring system, which is applied to measuring devices, harvesters, and optical devices, etc., can solve problems such as instability and unreliability, and achieve the effect of improving accuracy and avoiding the influence of vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

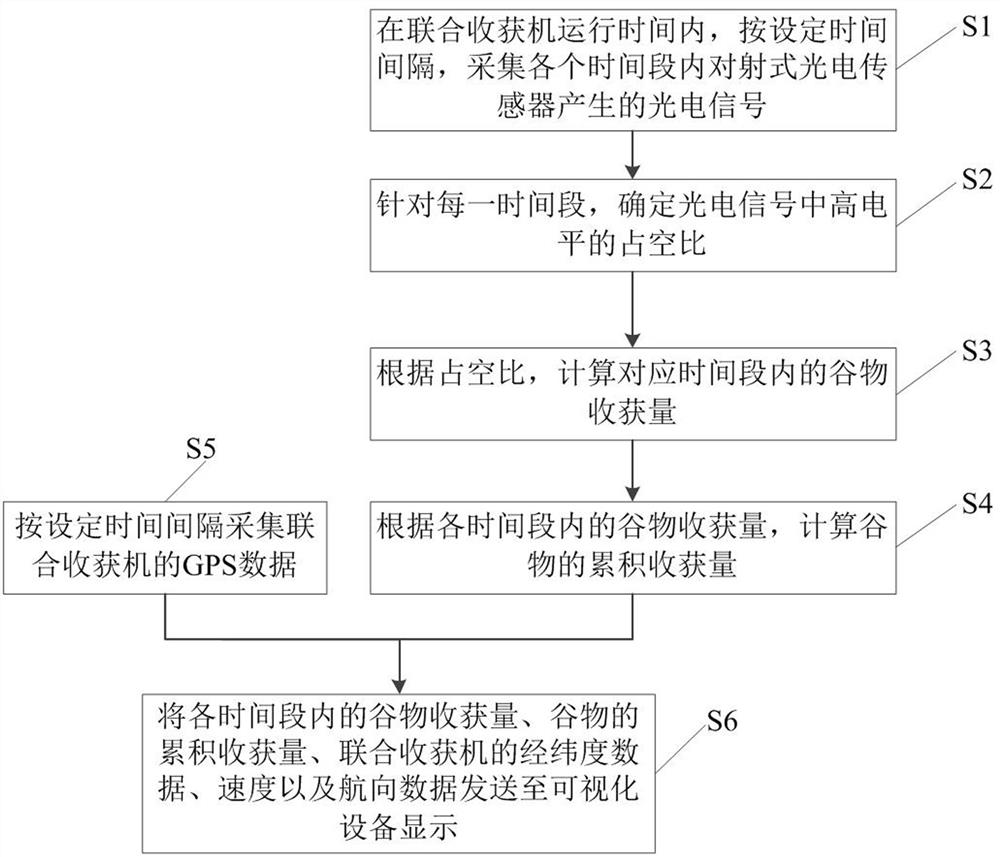

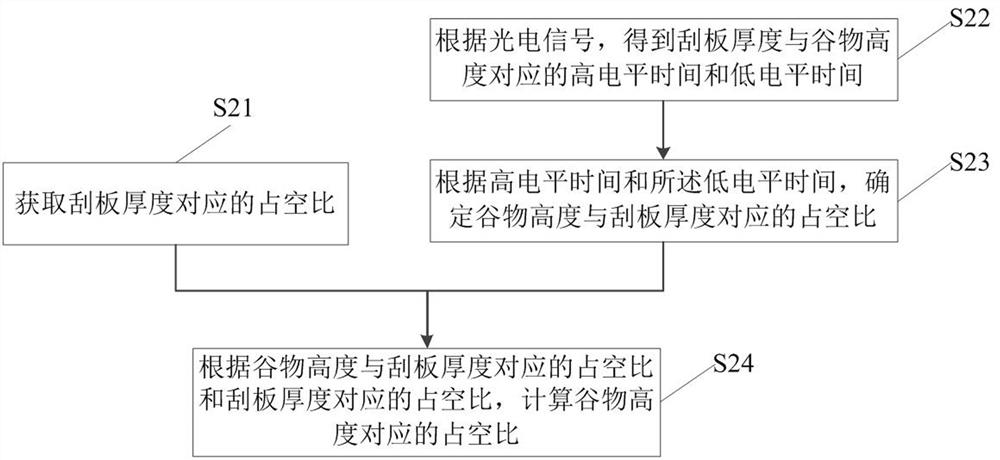

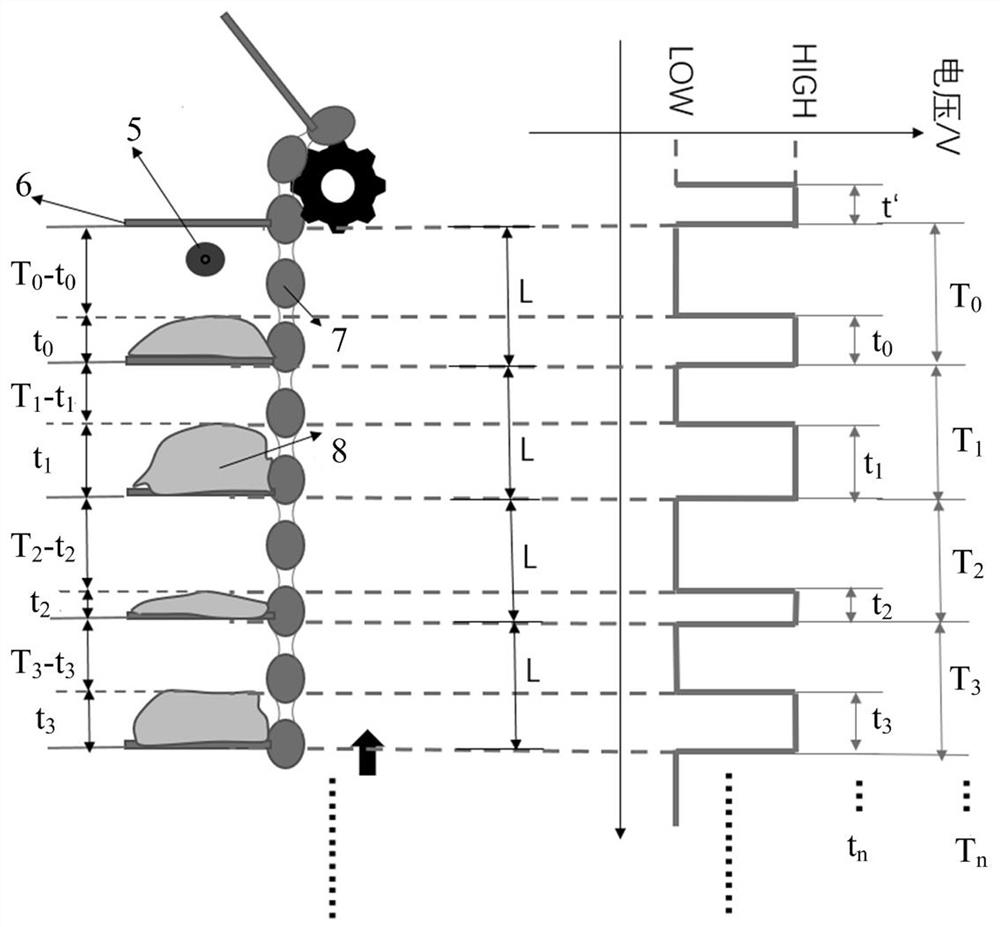

[0058] Object of the present invention is to provide a combine harvester harvest monitoring method, system and device, by the runtime combine harvester, at set time intervals, collecting a photoelectric beam photoelectric sensor generates a respective time period region is a combine harvester operating region of the blade between the signal beam photoelectric sensor photo signal emitter and a photoelectric signal receiving terminal, and run on the radio path and the blade path signal transmitting end and the receiving end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com