Fluff grabbing device for sheep breeding and implementation method of fluff grabbing device

A grabbing device and fluff technology, which is applied in the field of fluff grabbing devices for sheep breeding, can solve the problems of cumbersome grabbing process and long time consumption, and achieve simple grabbing, large amount of grabbing, simplified grabbing equipment and grasping Take the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

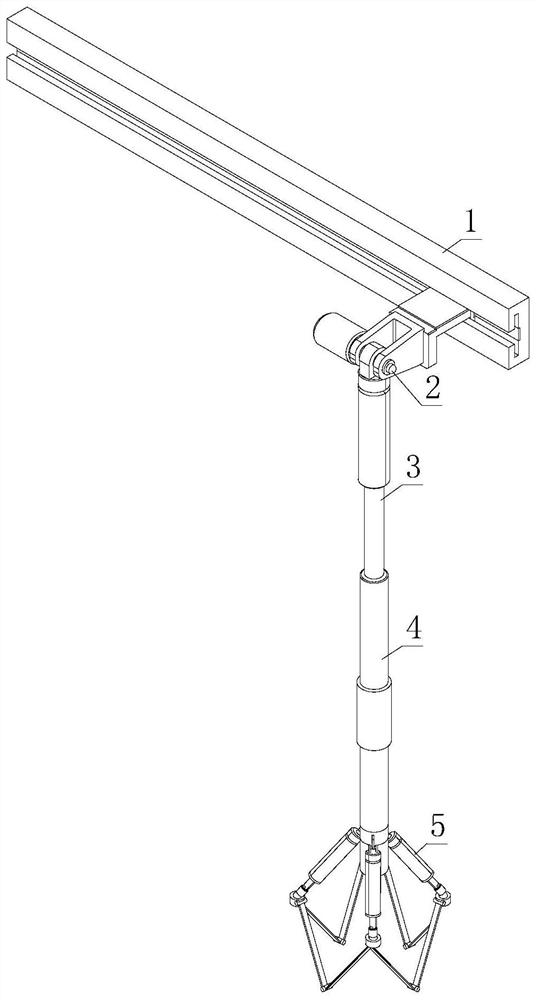

[0034] See figure 1 A sheep farming fluff with gripping means including a transport mechanism, diverting means 2, the lifting means 3, 4 and pin assembly extraction unit 5 is connected to the means conveying mechanism 2, the reversing mechanism 2 3 is fixedly connected to the lifting mechanism, the lifting mechanism 3 is fixed to the lower end connected to a pin assembly 4, the outer wall 4 is mounted a pin assembly extraction unit 5.

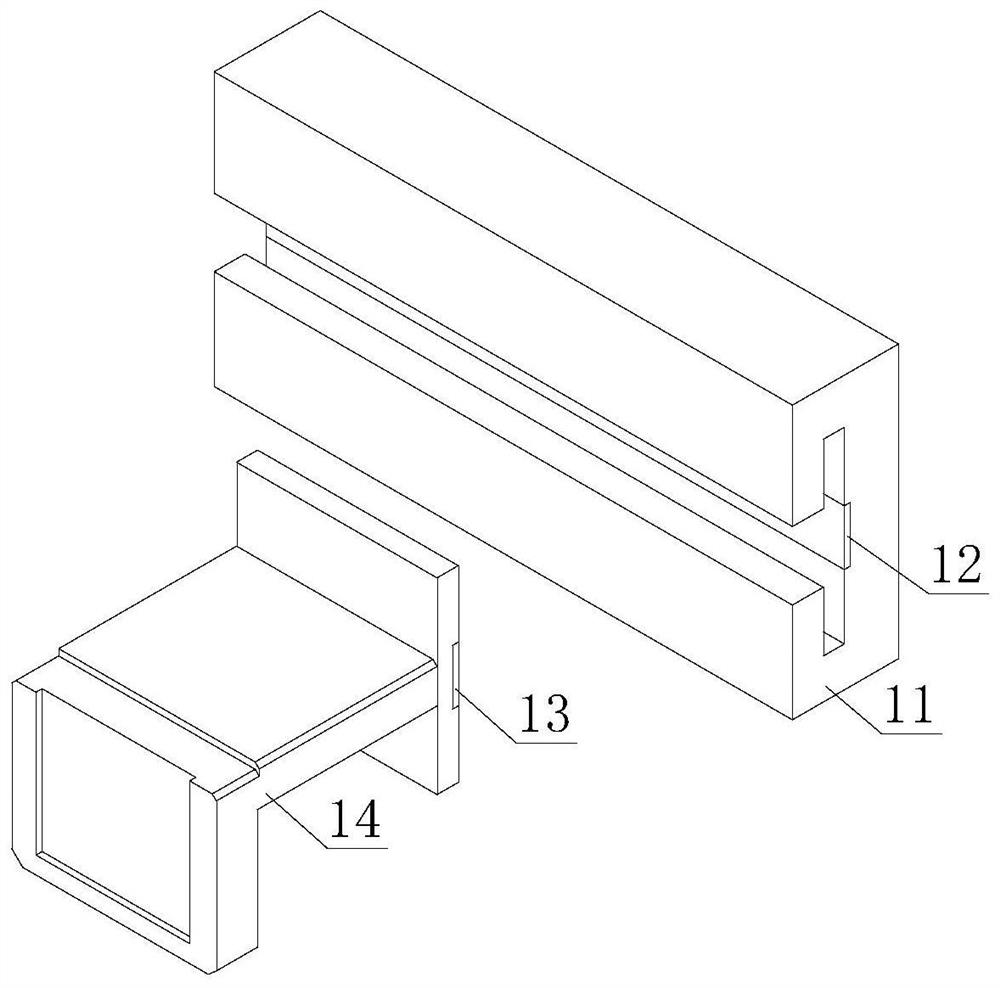

[0035] See figure 2 , A transport mechanism comprises a slide 11, guide the magnetic stripe 12, the magnetic navigation sensors 13 and the slider 14 slides on the slide rail 11 is connected with a slider 14, a magnetic navigation sensors 14 mounted on the slider 13, mounted on rails 11 guide the magnetic stripe 12, between the guide 13 and the magnetic stripe 12 is connected to each other navigation sensors.

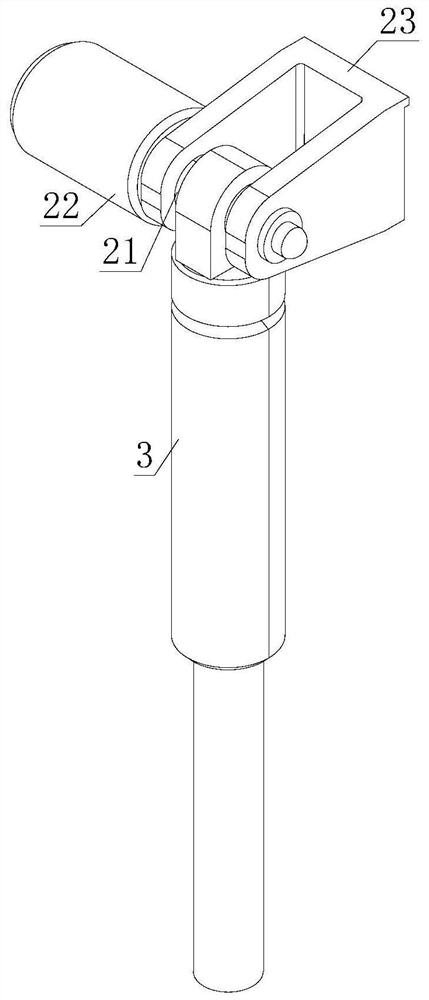

[0036] See image 3 , For a U-shaped bracket 23 comprises a central axis 2 to 21, the rotary electric machine 22 and a U-shaped bracket 23 by...

Embodiment 2

[0040] See Image 6 The difference between the present embodiment and the embodiment is only that the present embodiment has added a plurality of sets of pins, and the gap between adjacent pins is limited to fluff movement, and it is conducive to grabbing, and it is used to expand the scope of grabbing of fluff. The championship is not strong, and a circular plate body 6 is provided between the pin assembly 4 and the lift mechanism 3, at least three auxiliary grab mechanism 7 is provided at least three auxiliary crawler 7 at least three of the lower surface edges of the circular plate body 6. The structure of the auxiliary grab mechanism 7 is consistent with the structure of the pin assembly 4, and the secondary end of the auxiliary grab mechanism 7 is connected to the extraction mechanism 5.

Embodiment 3

[0042] See Figure 7 The difference between the present embodiment and the embodiment is only that the present embodiment has an extraction mechanism 5 in the vertical direction in the pin assembly 4, and at least two loop grooves 44 are opened on the outer wall of the pin assembly 4. There is a extraction mechanism 5, multi-hierarchical support, to accumulate thicker fluff grabbing, avoiding the fluffs above the pin, and enlarge the amount of fluffs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com