A cutting mechanism of waste wire automatic dismantling equipment

A waste wire, automatic technology, used in circuits, electrical components, electronic waste recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

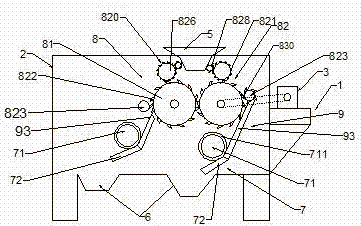

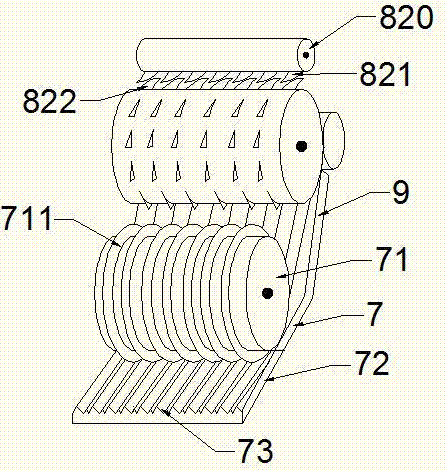

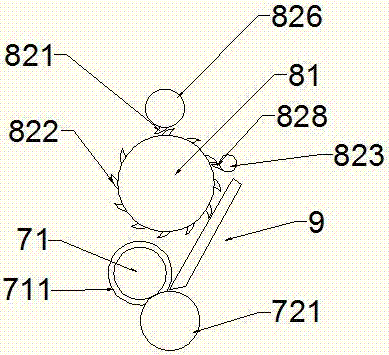

[0018] The present invention provides a cutting mechanism for automatic dismantling equipment for waste electric wires. The wire cutting mechanism 7 includes a cutter drum 71 fixed in the body 2 and a cutter pad assembled parallel to the cutter drum 71. The cutter drum 71 is linked with the output shaft of the speed governor 3; more than two wire inlet grooves 73 are arranged on the cutter pad surface, and the wire inlet grooves 73 are connected to the wire feeder on the wire feeder mechanism 9. The grooves cooperate with each other; the circumferential surface of the cutter drum 71 is radially provided with more than two annular cutting knives 711 that cooperate with the wire inlet groove 73 .

[0019] As a further improvement of the present invention, the cutter stopper is a baffle cutter stopper 72, and the baffle cutter stopper 72 is integrally connected with the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com