Dust-air separation device applied to dust cup of dust collector and dust collector

A technology for dust and gas separation and vacuum cleaners, which is applied in the direction of vacuum cleaners, applications, suction filters, etc., and can solve the problem of low efficiency of dust and gas separation in dust cups of vacuum cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

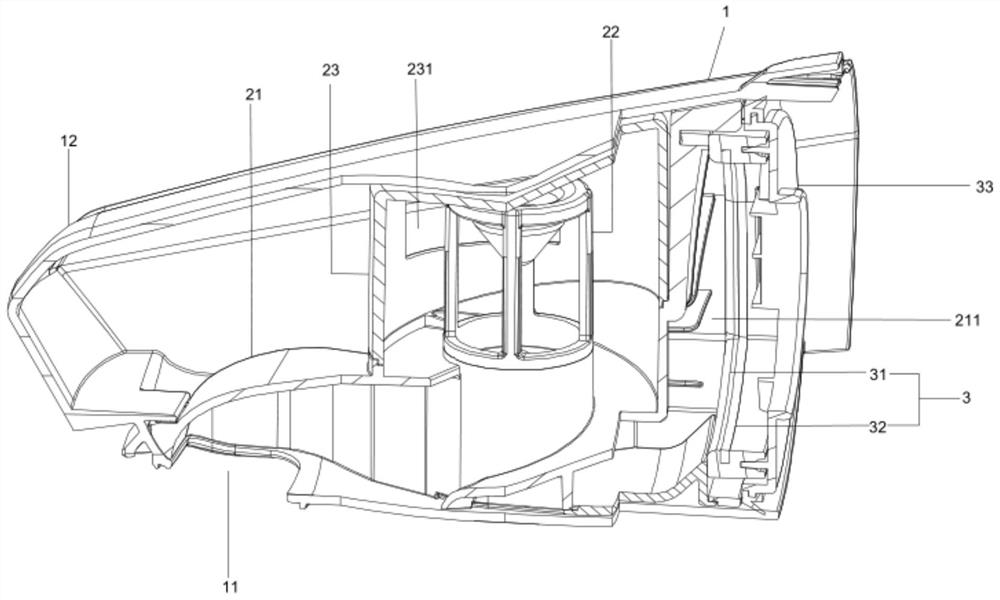

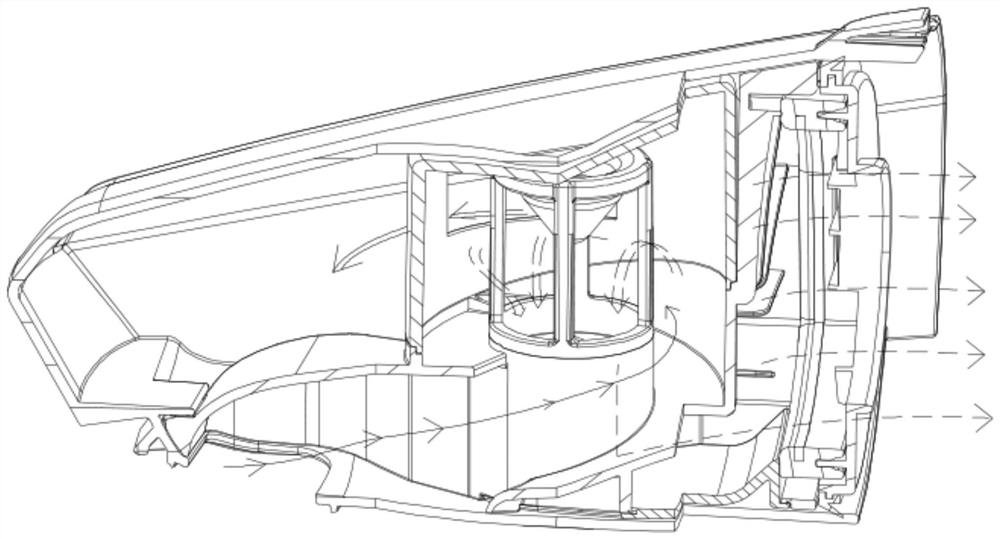

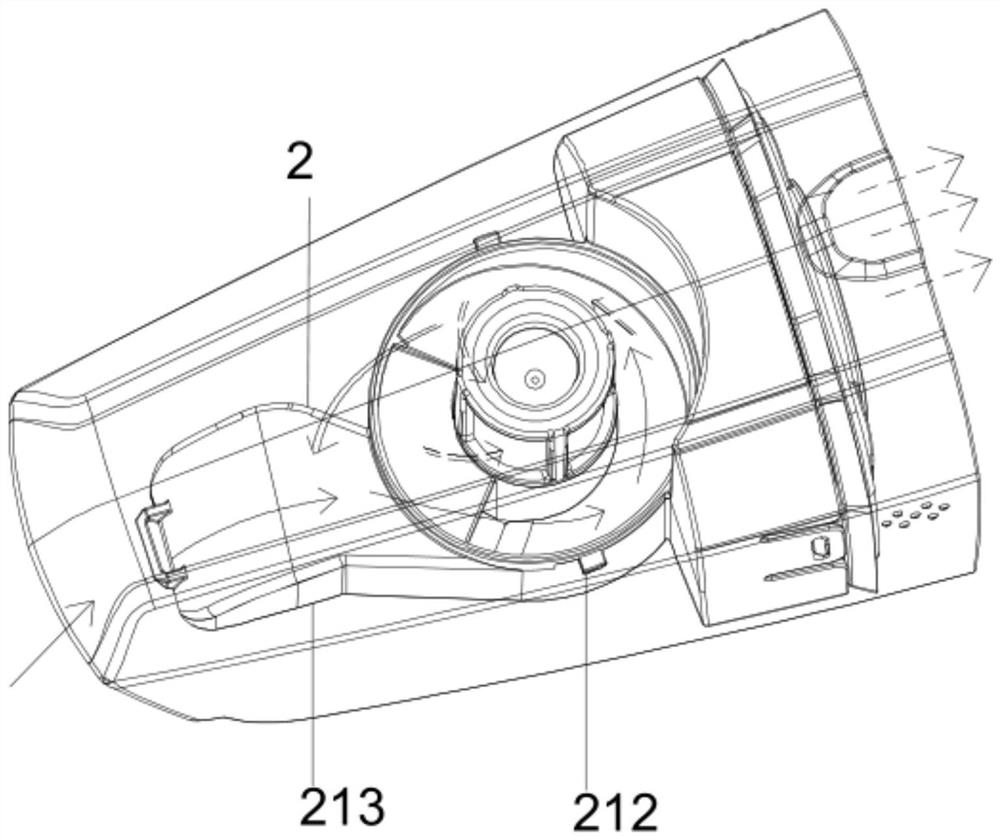

[0027] see Figure 1 to Figure 7 , the figure shows a dust and gas separation device applied to the dust cup of the vacuum cleaner provided by Embodiment 1 of the present invention, which includes a dust cup main body 1, an air inlet 11 is provided at the bottom of the dust cup main body 1, and the dust cup main body 1 A dust bucket 12 is arranged on the top, and a dust-gas separation component 2 is arranged in the dust-gas bucket 12. The dust-gas separation component 2 includes a filter channel 21 and a cyclone cone 22. One end of the filter channel 21 is connected with the air inlet 11, and the filter channel The other end of 21 is provided with an air outlet 211, and the filter channel 21 spirally rises, and the cyclone cone 22 is installed above the filter channel 21, and the filter channel 21 is connected with a dust-removing wind cover 23, and the cyclone cone 22 is located in the dust-removing wind cover 23 , the ash-throwing wind cover 23 is provided with an ash-throwi...

Embodiment 2

[0036] see Figure 1 to Figure 7 , the figure shows a dust and gas separation device applied to the dust cup of the vacuum cleaner provided by the second embodiment of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The cyclone cone 22 is provided with a nylon mesh cone 221, and the interior of the nylon mesh cone 221 has a concave cone surface. After testing and research, we found that the concave cone shape of the nylon mesh cone can effectively improve the separation effect. According to the test data, the vacuum degree will lose 8% more without the concave conical surface.

Embodiment 3

[0038] see Figure 1 to Figure 7, the figure shows a dust and gas separation device applied to the dust cup of the vacuum cleaner provided by the third embodiment of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Get rid of ash mouth 231 and offer on the circumferential side wall of get rid of ash wind cover 23, the dust direction that throws off from ash port 231 is tangent to the tangential extension line of the opening position of get rid of ash port 231. In the above improvement, the ash-throwing port is set on the circumferential side wall of the dust-throwing wind hood, and the direction of the dust thrown out from the ash-throwing port is tangent to the tangential extension line of the opening position of the ash-throwing port. , due to the effect of centrifugal force, the wind speed in the area of the ash throwing port is fast, and the dust will be blown up again ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com