Patents

Literature

33results about How to "Solve the problem of low separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

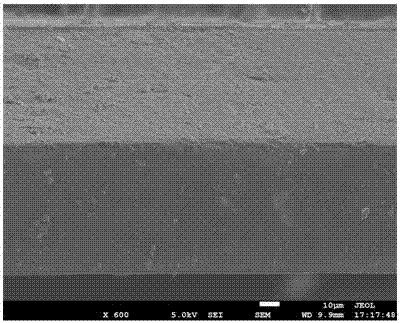

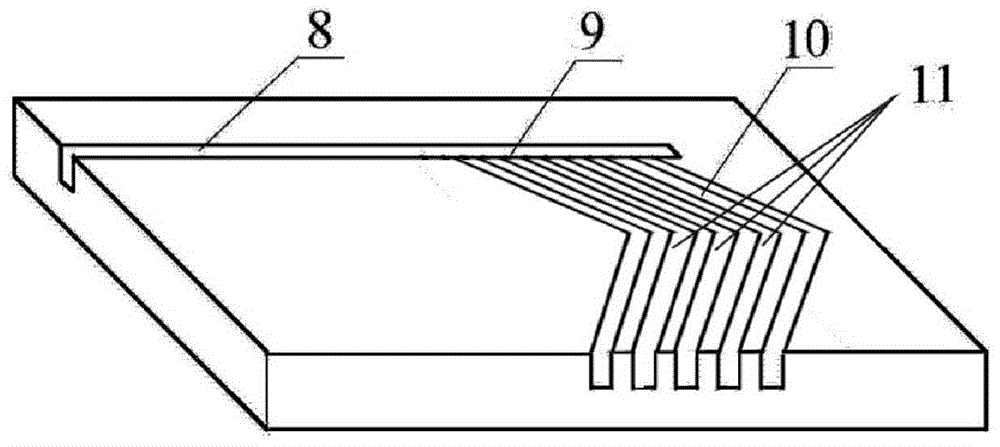

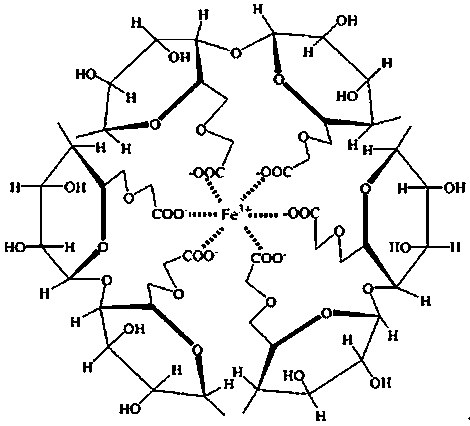

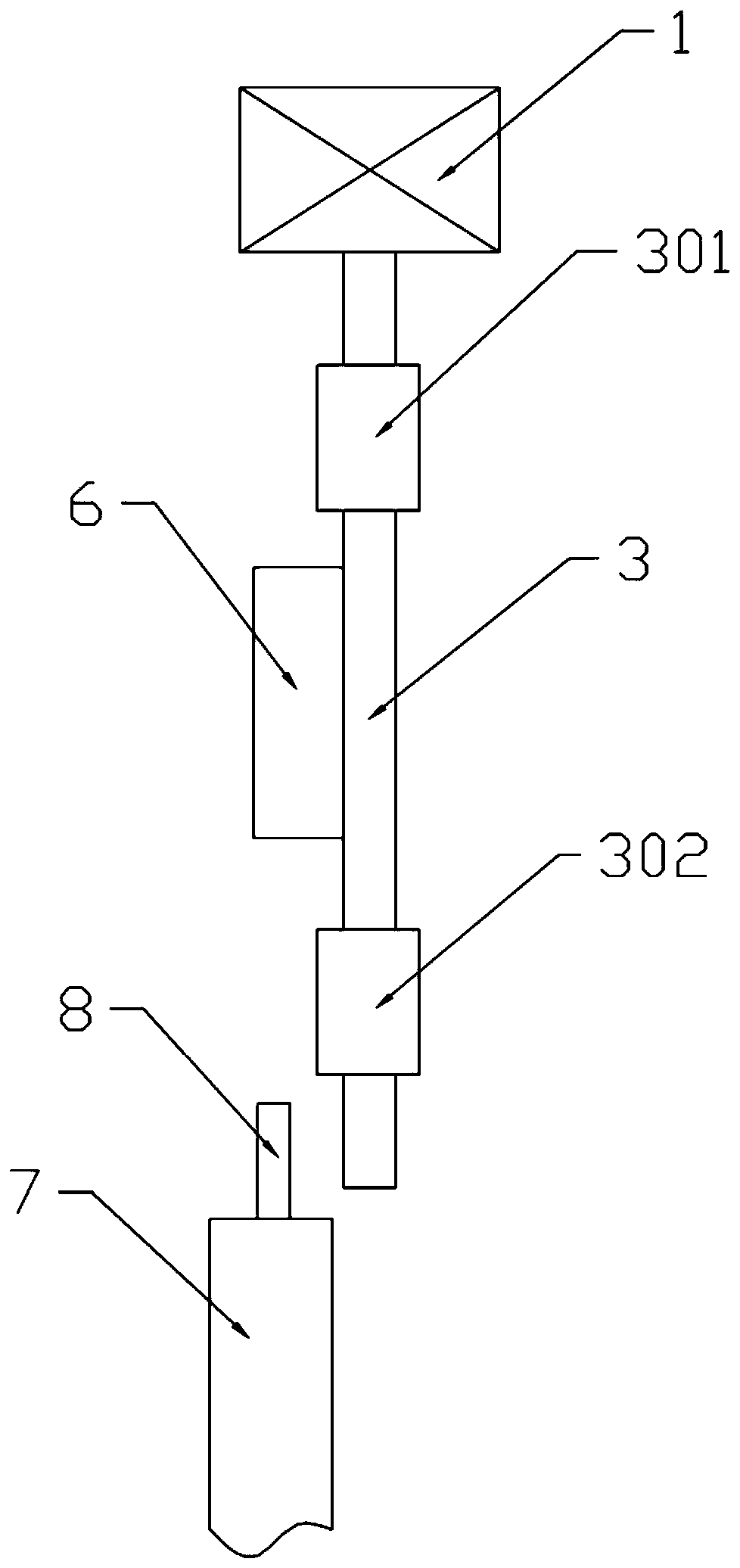

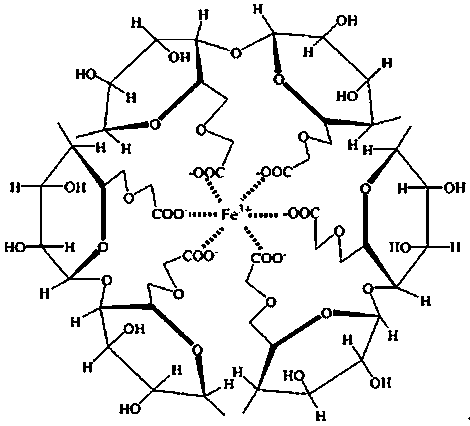

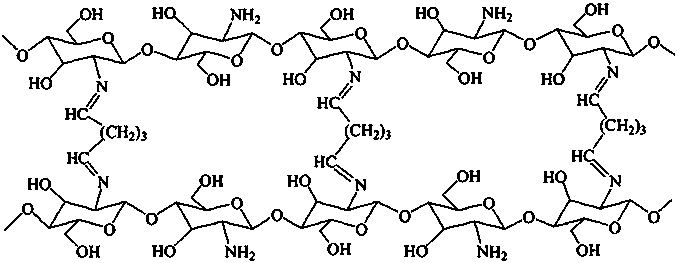

Preparation of photoelectric catalytic membrane for preparing hydrogen by decomposing water

ActiveCN104117391AEasy reunionHigh hydrogen quantum efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDiaphragmsHydrogen purityPtru catalyst

The invention relates to the preparation of a photoelectric catalytic membrane for preparing hydrogen by decomposing water. The preparation method comprises the steps of mixing sodium cellulose acetate or sodium carboxymethyl cellulose with polyvinylpyrrolidone; heating by distilled water, and stirring for dissolving; spreading the product on a flat glass plate, and drying to form a membrane; crosslinking by heavy metal ions; soaking in solution containing anion groups, and drying at the room temperature to obtain a thin membrane; evenly dispersing oxyhalide bismuth catalyst in absolute ethyl alcohol under ultrasonic oscillation, pouring the mixed solution onto the surface of the thin membrane, and drying by air; mixing chitosan and polyvinylpyrrolidone, and dispersing the mixture; heating by acetic acid water solution, and stirring for dissolving; feeding an aldehyde crosslinking agent for crosslinking, and then pouring the product onto the oxyhalide bismuth thin membrane to obtain the photoelectric catalytic membrane. The photoelectric catalytic membrane is used for preparing the hydrogen by decomposing water, and is capable of effectively separating photoproduction electron holes; the hydrogen production quantum efficiency reaches up to 90-96%, the hydrogen purity reaches up to 99-99.9%, and 15-40% of energy consumption can be saved, so that a new way is provided for preparing hydrogen by decomposing water through photoelectrocatalysis.

Owner:TAIYUAN UNIV OF TECH

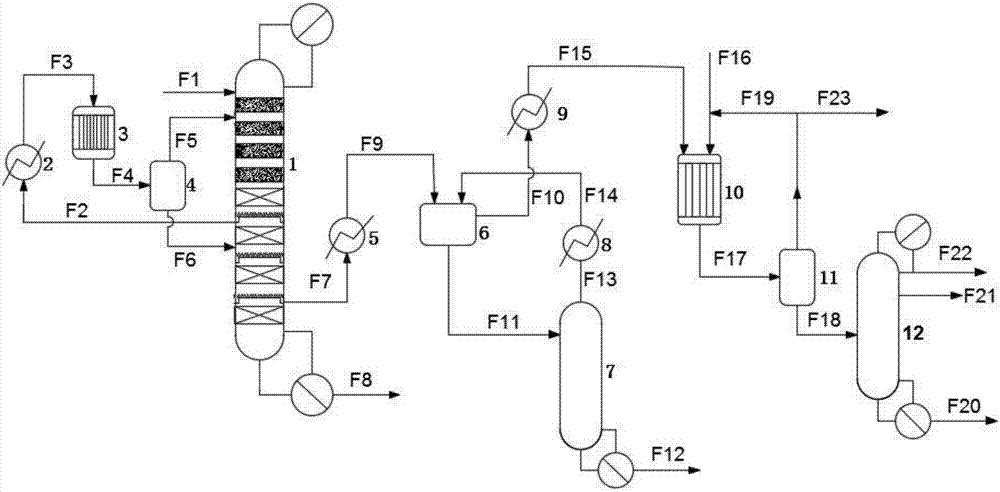

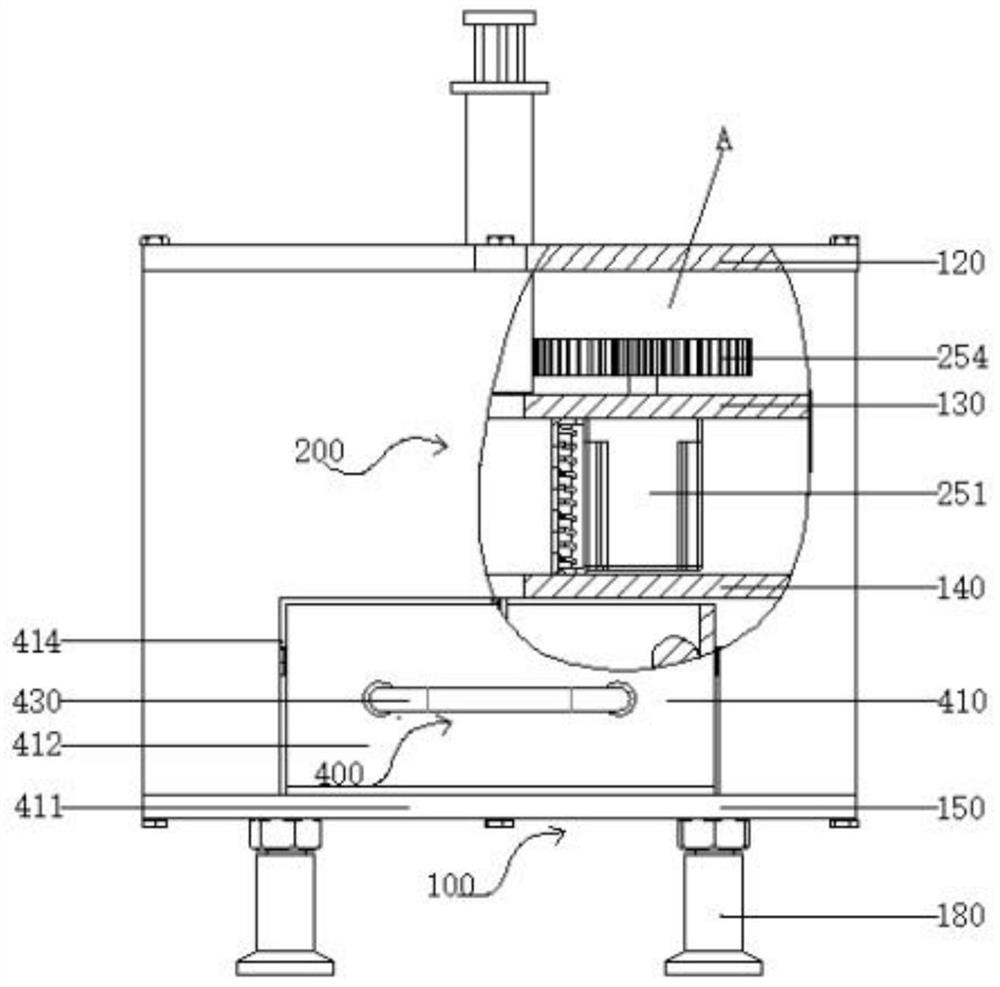

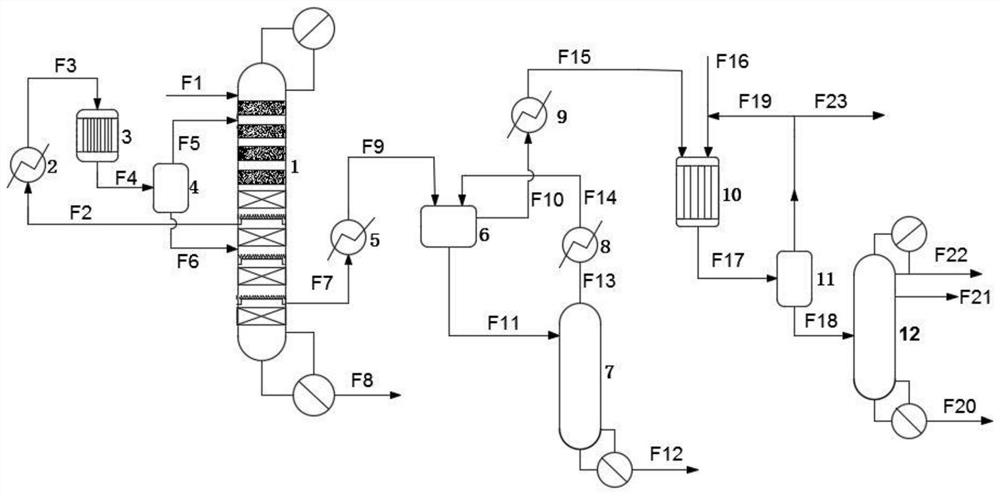

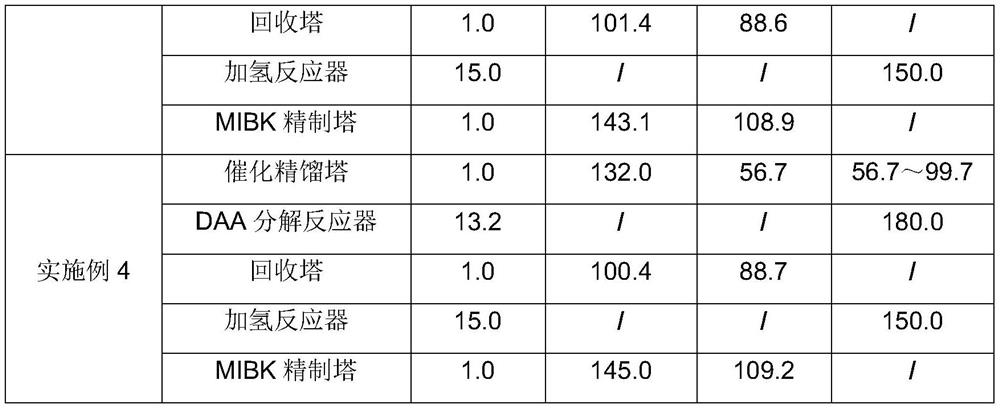

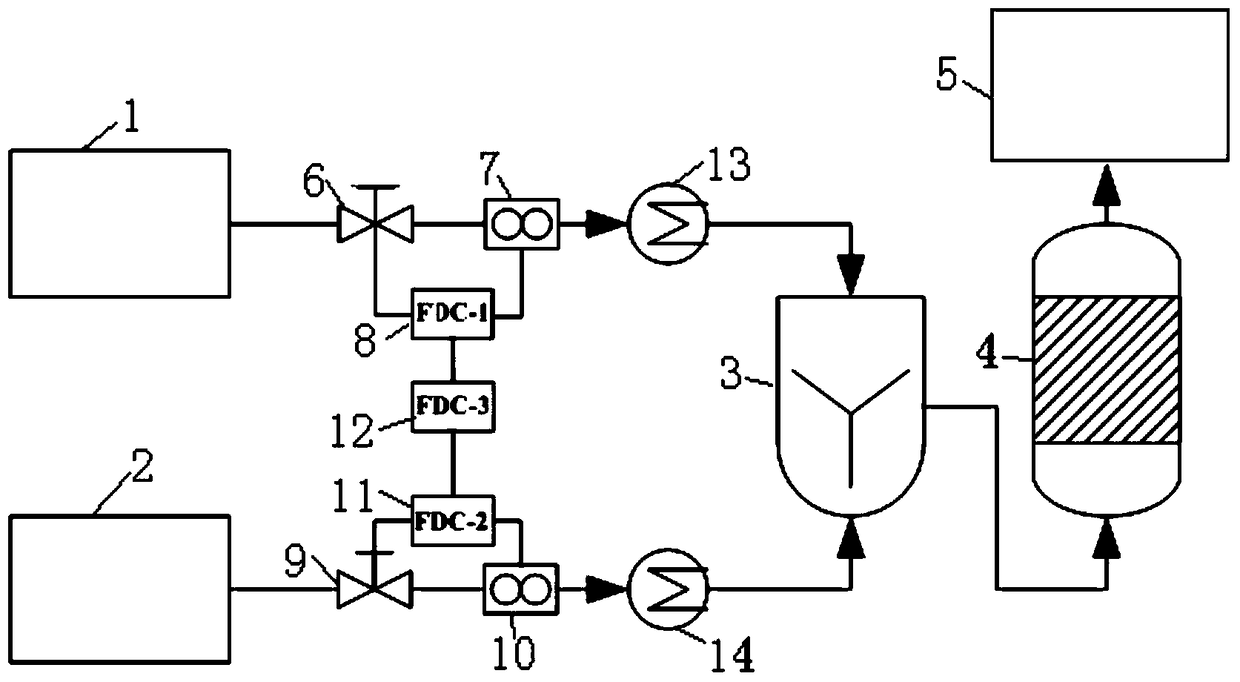

Method and equipment thereof for synthesizing methyl isobuthl ketone with acetone two-step method

ActiveCN108002995AMild operating conditionsLow equipment requirementsOrganic compound preparationEnergy inputDecompositionCatalytic distillation

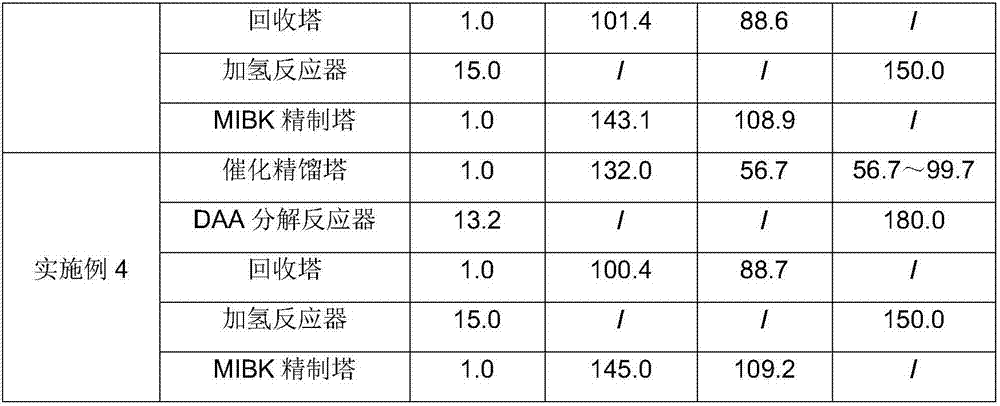

The invention discloses a method and equipment thereof for synthesizing methyl isobuthl ketone with an acetone two-step method. The method includes the steps that a, DAA and MSO are generated by condensation and dehydration of the raw material of acetone in a catalytic distillation column, products rich in MSO and water are side taken off from the catalytic distillation column; b, a material containing DAA is side taken off from the catalytic distillation column, and put into a DAA decomposition reactor, DAA in the material is transformed into acetone and MSO, the products are separated by flash evaporation to obtain a gas phase rich in acetone and a liquid phase rich in MSO and water, the gas phase and the liquid phase are respectively circulated back to the column; c, the liquid phase products in the step a are cooled and divided into phases, an organic phase rich in MSO and a water phase containing small amounts of organic matter are obtained, the water phase enters into a recoverytower to recycle organic matter; d, MIBK is generated by the hydrogenation of the organic phase in the step c, after hydrogen gas is recycled by flash evaporation, then enters into an MIBK refining tower, and a MIBK product is side taken off. The total conversion rate of acetone is 99.0%, and the product MIBK purify is up to 99.5%.

Owner:长成新能股份有限公司 +1

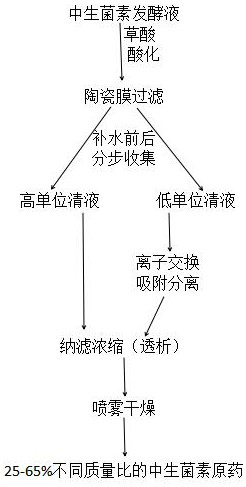

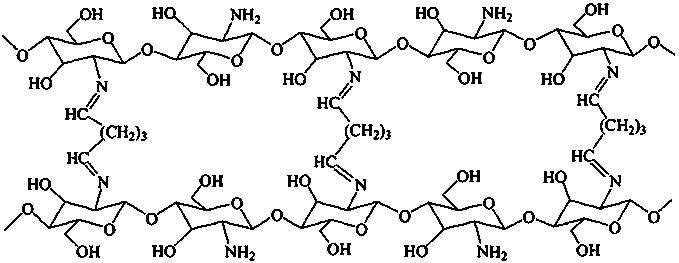

Method for efficiently separating zhongshengmycin from fermentation liquor

PendingCN113896753ASolve the problem of low separation efficiencyReduce manufacturing costSugar derivativesSugar derivatives preparationBiotechnologyCeramic membrane

The invention relates to a method for efficiently separating zhongshengmycin from fermentation liquor. The core process method comprises the following steps of: filtering the fermentation liquor by a ceramic membrane, and performing cation resin exchange adsorption separation on low-unit ceramic clear liquid of the ceramic clear liquid, wherein the elution yield is 90-95%; independently concentrating and spray-drying the analytical liquid, or mixing with high-unit concentrated mother liquor of the ceramic clear liquid according to a ratio of 1: 1-1: 3, concentrating and spray-drying, wherein the content of the obtained zhongshengmycin raw drug is 25-65%, the total yield is improved by 16-20% compared with the raw drug, and the color and purity of the raw drug are greatly improved compared with 12-24% granular products in the market. According to the method disclosed by the invention, the problems of low separation efficiency of the low-unit mother liquor of the zhongshengmycin and high degradation rate in the production process are solved, the raw drugs with different mass ratios are obtained, the production yield is improved, and the production cost is effectively reduced.

Owner:陕西麦可罗生物科技有限公司

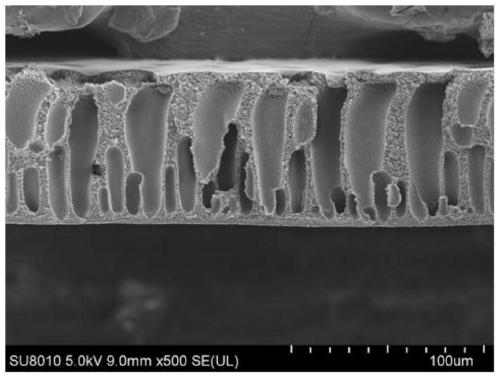

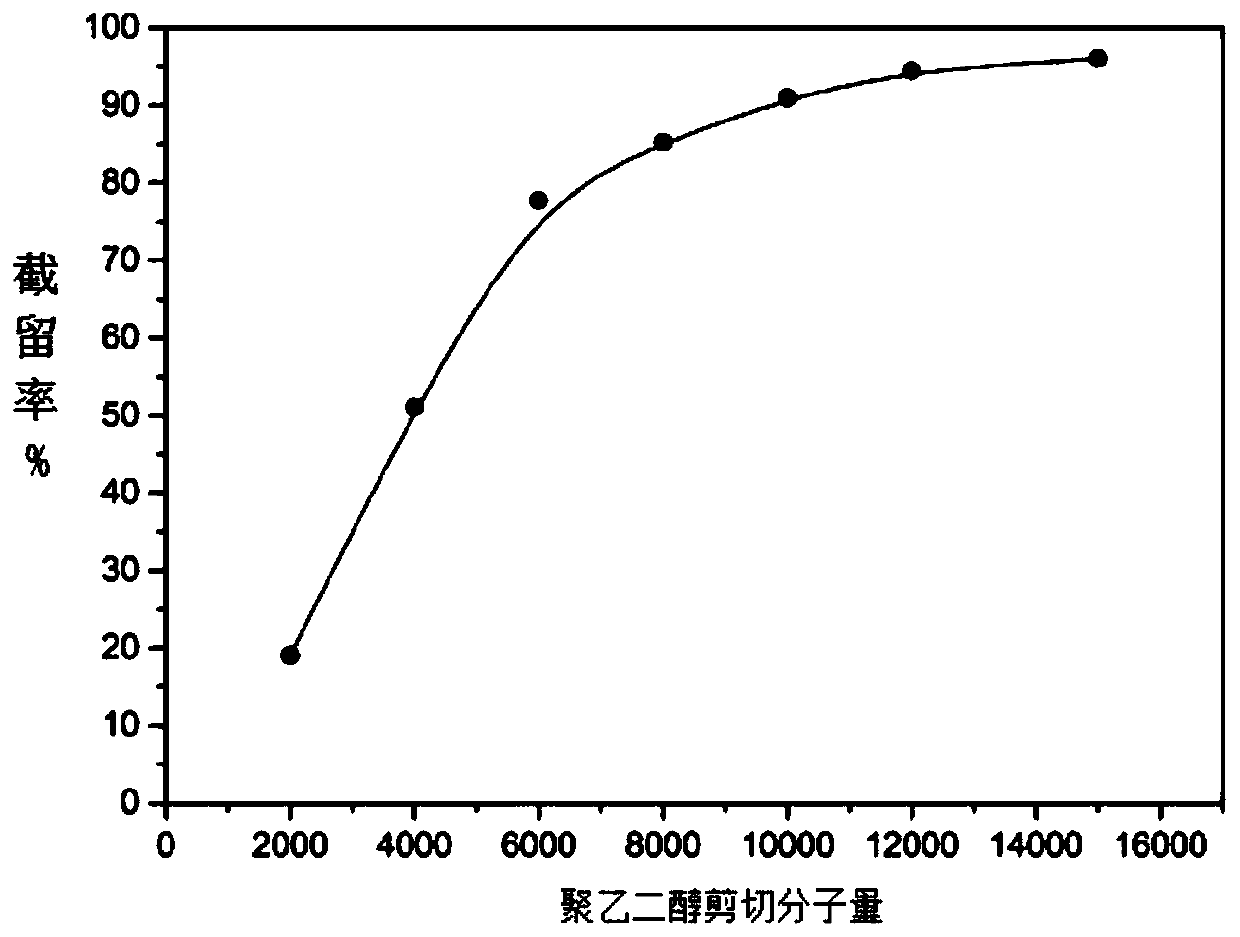

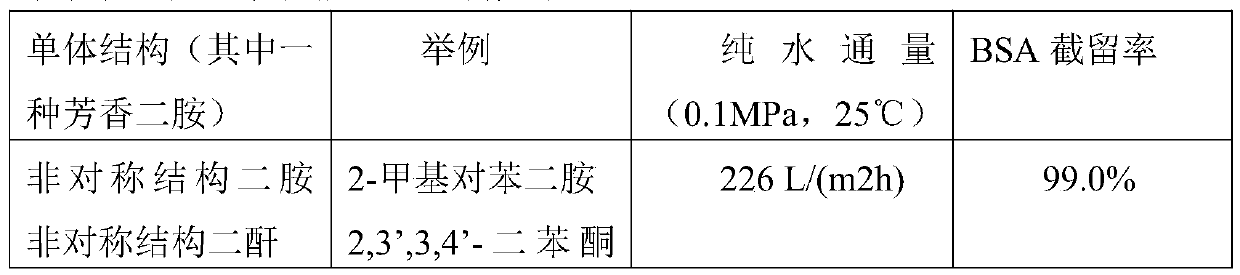

Preparation method of high-flux polyimide composite ultrafiltration membrane

InactiveCN109745875ASolve the problem of low separation efficiencyLow costUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiltrationUltrafiltration

The invention discloses a preparation method of a high-flux polyimide composite ultrafiltration membrane. The method comprises the following steps: step (1), dissolving two types of aromatic diamine into a solvent, then adding aromatic dianhydride, and stirring to perform reaction, so as to obtain a polyamic acid solution; step (2), adding a catalyst and a dehydrating agent into the polyamic acidsolution obtained in the step (1), stirring to perform a reaction, cooling the solution to room temperature, dropwise adding methanol till the color of the solution completely becomes white from red,and performing suction filtration, so as to obtain solid powder, repeatedly washing through methanol and performing suction filtration, and drying, so as to obtain polyimide solid powder; step (3), dissolving the polyimide solid powder obtained in the step (2) into a solvent, stirring and dissolving, coating the powder onto a supporting layer, and then forming the polyimide composite ultrafiltration membrane. The obtained high-flux polyimide composite ultrafiltration membrane is high in pure water flux, and the retention rate of bovine serum albumin BSA can reach 99.5 percent or higher. The method can solve the problem that in the prior art, the separation efficiency of a polyimide ultrafiltration membrane is low.

Owner:中复新水源科技有限公司

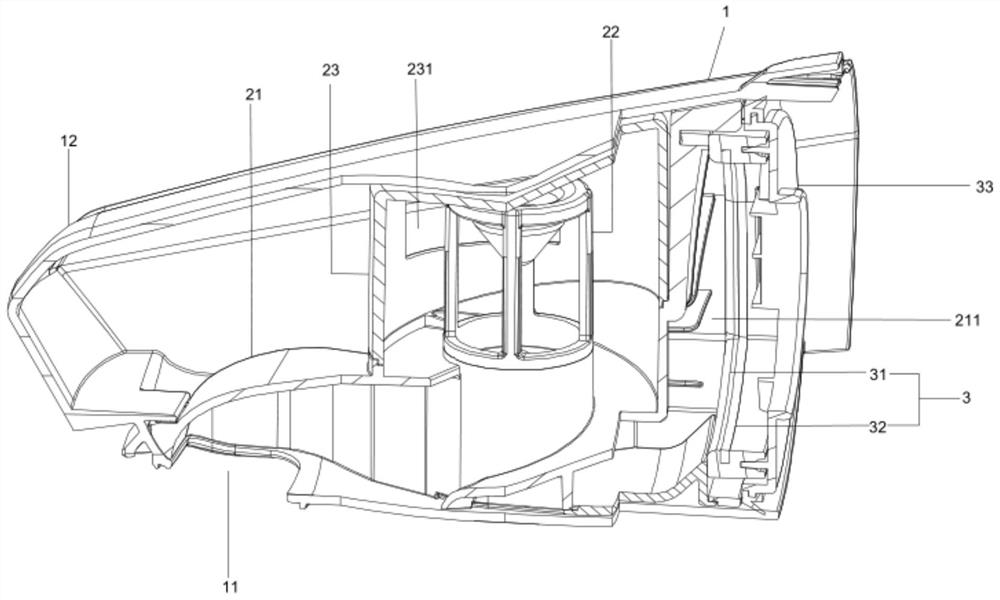

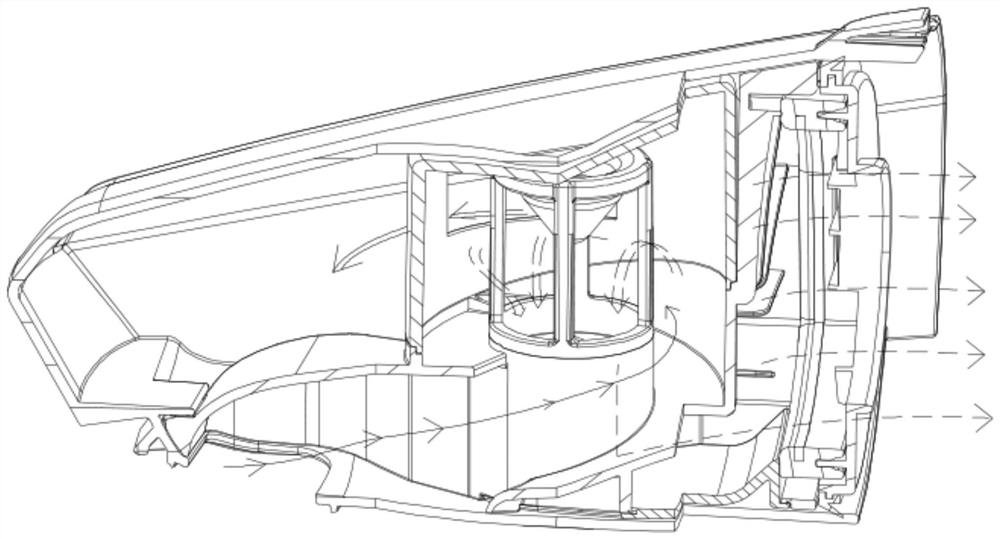

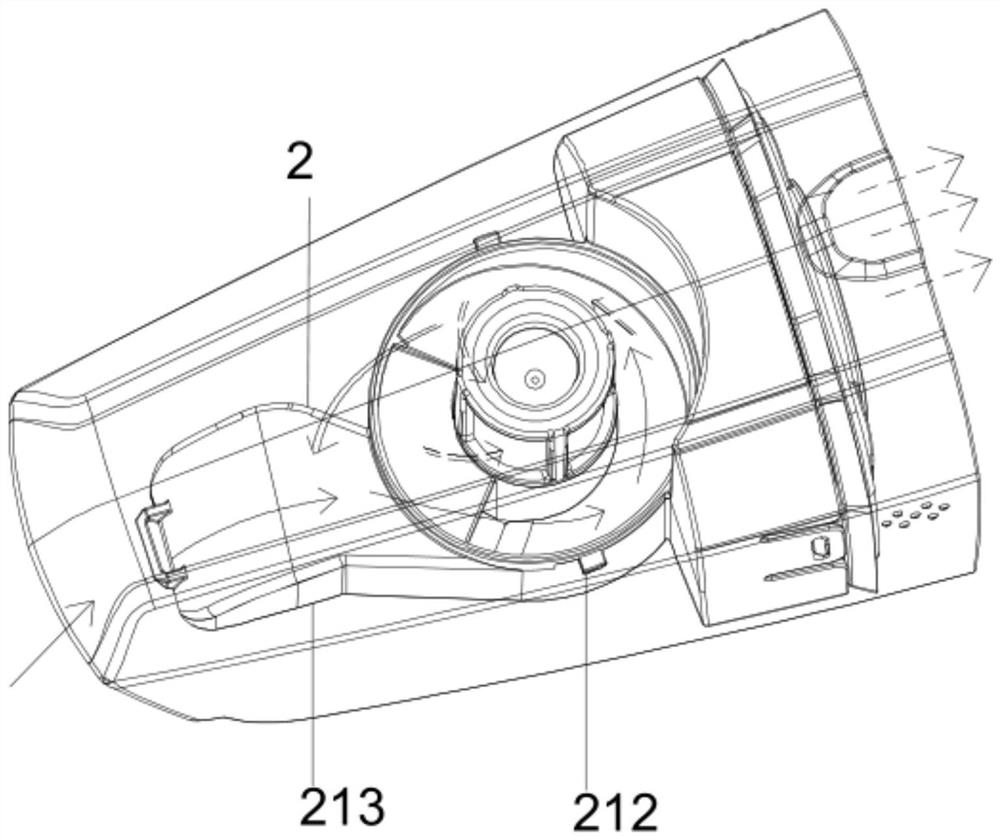

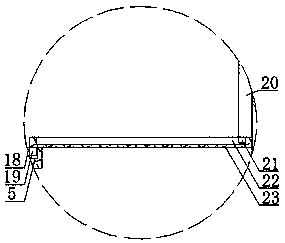

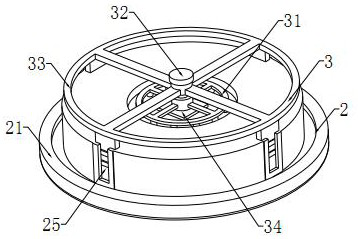

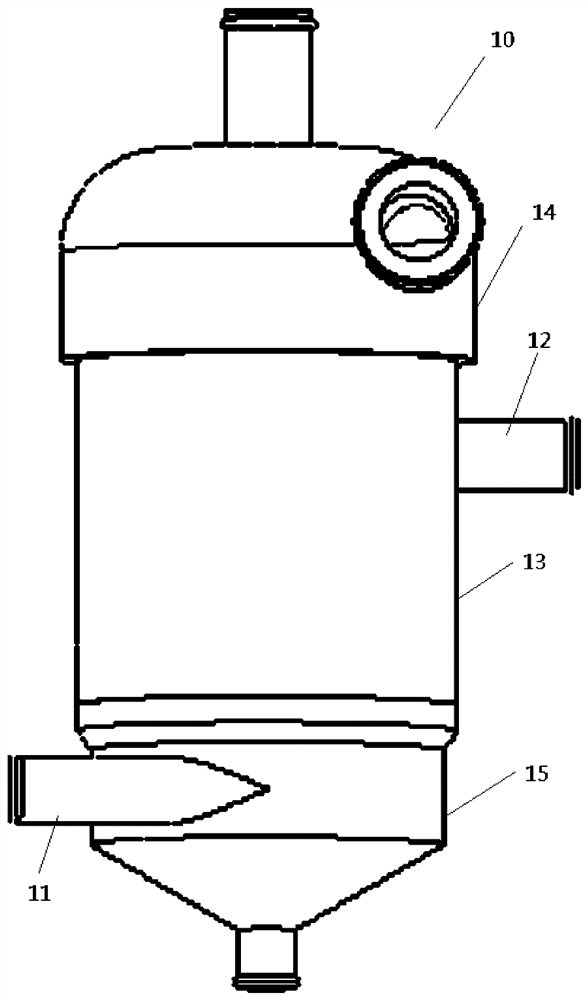

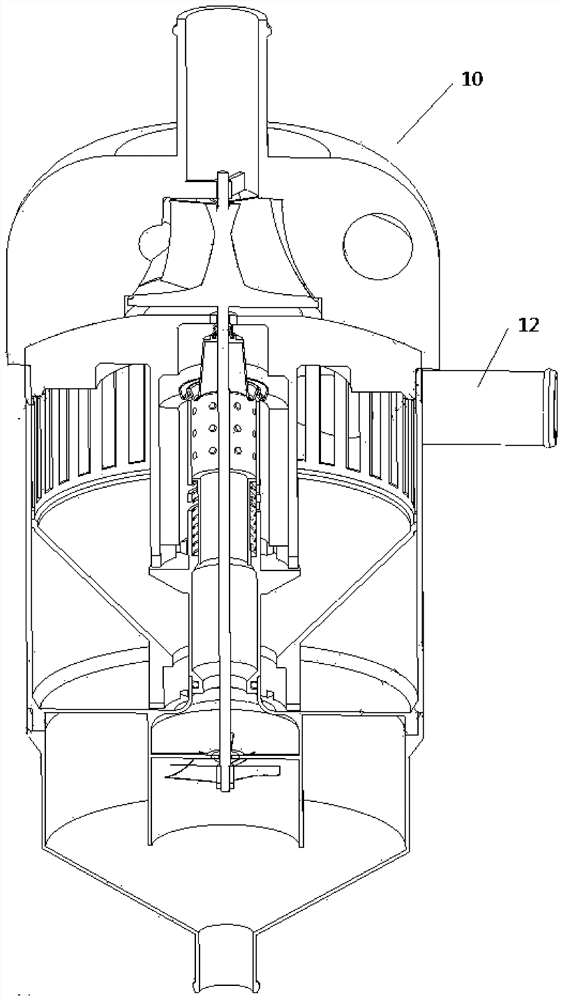

Dust-air separation device applied to dust cup of dust collector and dust collector

PendingCN113317718ASolve the problem of low separation efficiencyImprove separation efficiencySuction filtersAir separationEngineering

The invention provides a dust-air separation device applied to a dust cup of a dust collector, which comprises a dust cup main body, wherein an air inlet is arranged at the bottom of the dust cup main body, a dust accumulation barrel is arranged on the dust cup main body, a dust-air separation component is arranged in the dust accumulation barrel, the dust-air separation component comprises a filter channel and a cyclone cone, one end of the filter channel is communicated with the air inlet, an air outlet is formed in the other end of the filter channel, the filter channel spirally ascends, the cyclone cone is installed above the filter channel, an dust throwing fan cover is connected to the filter channel, the cyclone cone is located in the dust throwing fan cover, a dust throwing opening is formed in the dust throwing fan cover, dust-containing airflow enters the filter channel from the air inlet and is separated through the cyclone cone, then dust is thrown out of the dust throwing opening and enters the dust accumulation barrel, and the filtered dust-containing airflow flows out of the air outlet. The invention further provides the dust collector. Compared with the prior art, the problem that the dust cup of the dust collector is low in dust-air separation efficiency can be effectively solved.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

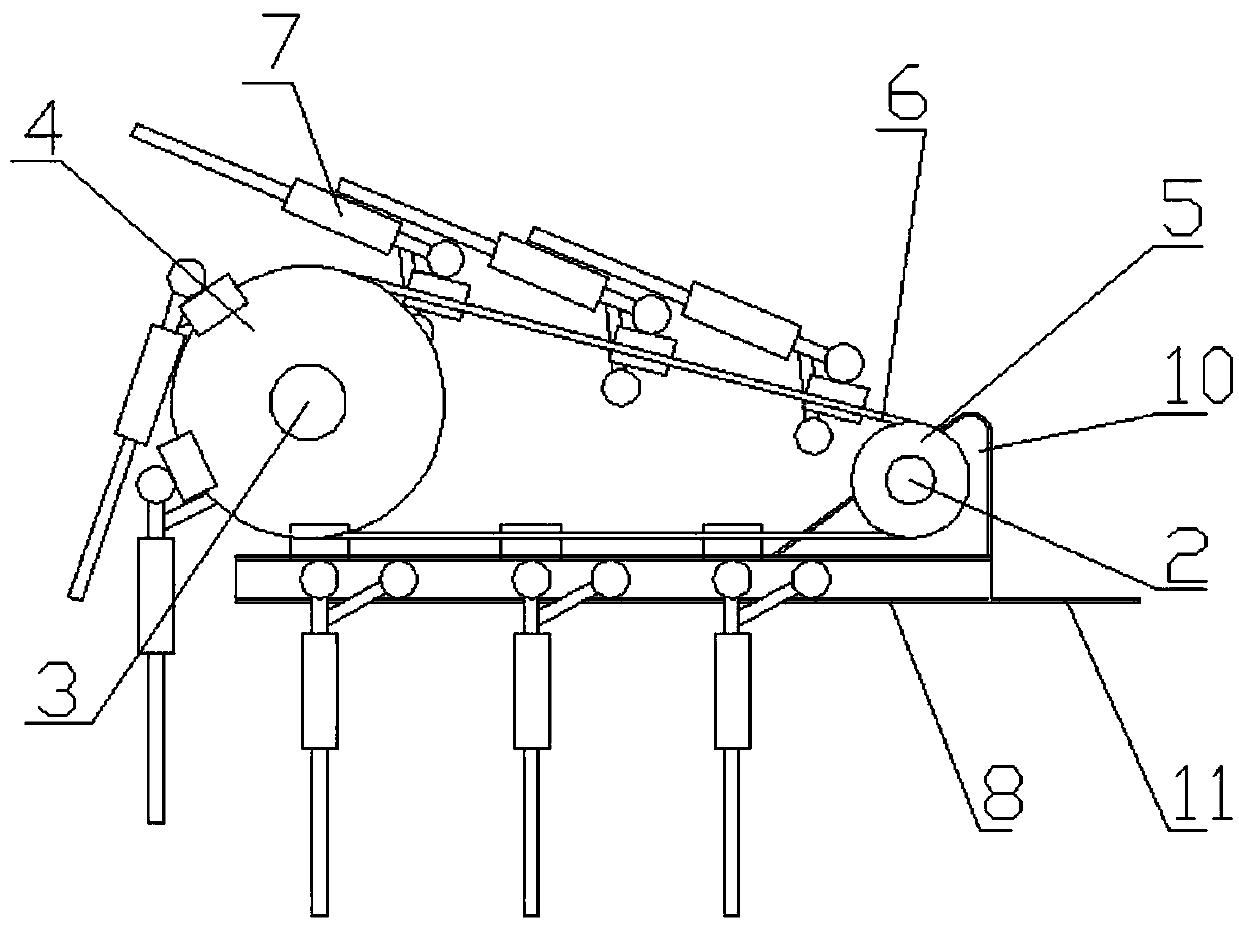

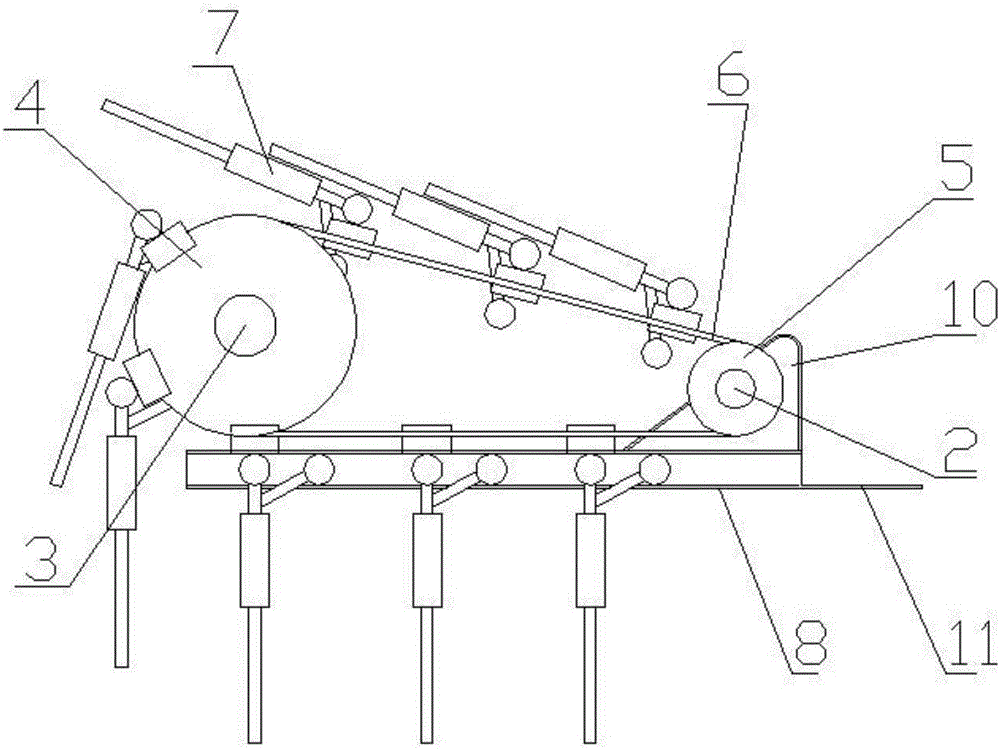

Tire bead wire separating device

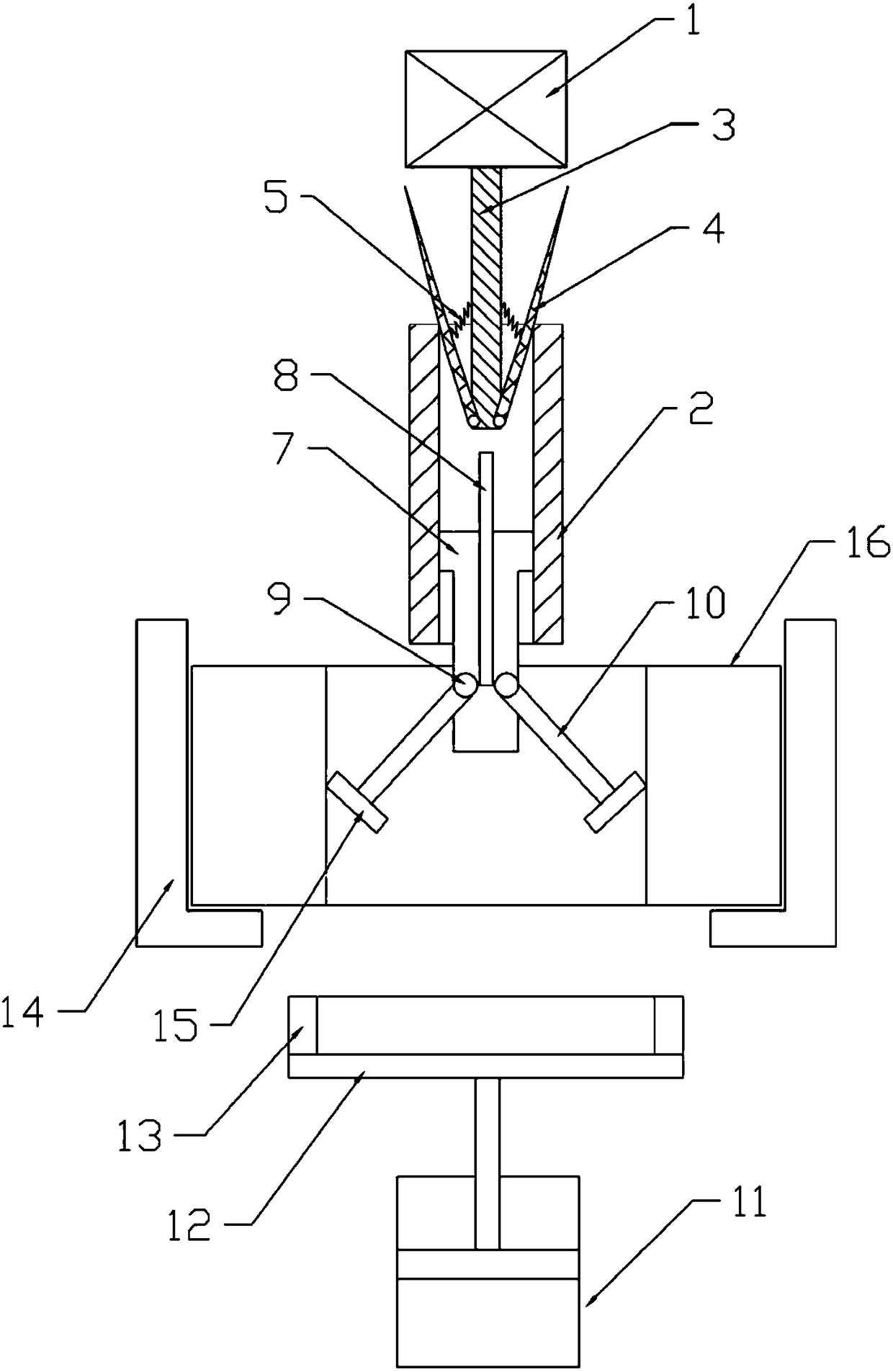

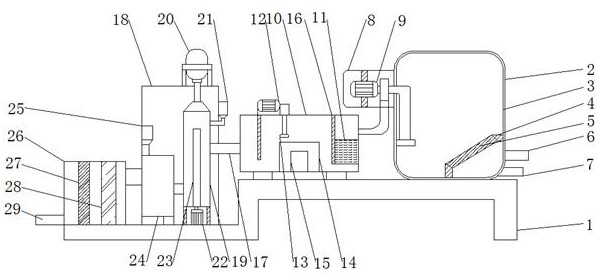

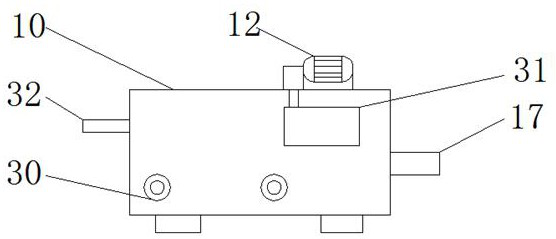

ActiveCN108556193AGood separation effectImprove efficiencyPlastic recyclingWaste tiresWaste treatment

The invention relates to a tire bead wire separating device, and belongs to the technical field of solid waste treatment. The tire bead wire separating device comprises a machine frame, wherein a motor, a fixing tube and a clamping device are installed on the machine frame from top to bottom, the motor is connected with a telescopic rod, and the telescopic rod is provided with a first telescopic section, a second telescopic section and cutters from top to bottom; the cutters are hinged to the telescopic rod, springs are connected between the cutters and the telescopic rod, and a push rod is connected to the side wall of the telescopic rod; a support rod is arranged in the fixing tube, the support rod is connected with a rack in a sliding mode, two gears are rotationally connected to the support rod, the gears are meshed with the rack, and the gears are coaxially connected with supporting bars; and a pulling device is arranged below the clamping device, the pulling device comprises an air cylinder, a working table is connected to the air cylinder, and electromagnets are connected to the working table. According to the technical scheme, a waste tire does not have relatively large deformation in the pulling process, furthermore, the whole pulling process is mechanical, the separating efficiency is high, the effect is good, and the practicability is high.

Owner:重庆九橡化大橡胶科技有限责任公司

Gas-liquid baffle separation device

InactiveCN105289112ASolve the problem of low separation efficiencySimple technical meansDispersed particle separationGas phaseInput control

A gas-liquid baffle separation device comprises an input control room, a pre-separator, a protection plate, separation rooms and the like, wherein the pre-separator comprises a plurality of layers of partitions which are piled up; a main inlet chute and a plurality of sub-chutes are formed in each partition; a gas-liquid mixture is assigned by the input control room to the main inlet chutes of all the partitions, droplet entrainment in air flow disappears, and liquid phases are uniformly distributed in the form of a liquid membrane along the circumferences of all the main inlet chute to form annular flow; after the annular flow passes through the sub-chutes of all the partitions, the liquid phases gather in two sub-chutes which are formed in the head and tail parts respectively, and gas phases gather concentrated in the middle sub-chutes for gas-liquid pre-separation; after the gas-liquid pre-separation is finished, gas and a liquid are separately connected into the three separation rooms for separation again. Through adoption of the device, efficient gas-liquid separation is achieved.

Owner:LUOYANG CHENXIANG MACHINERY TECH CO LTD

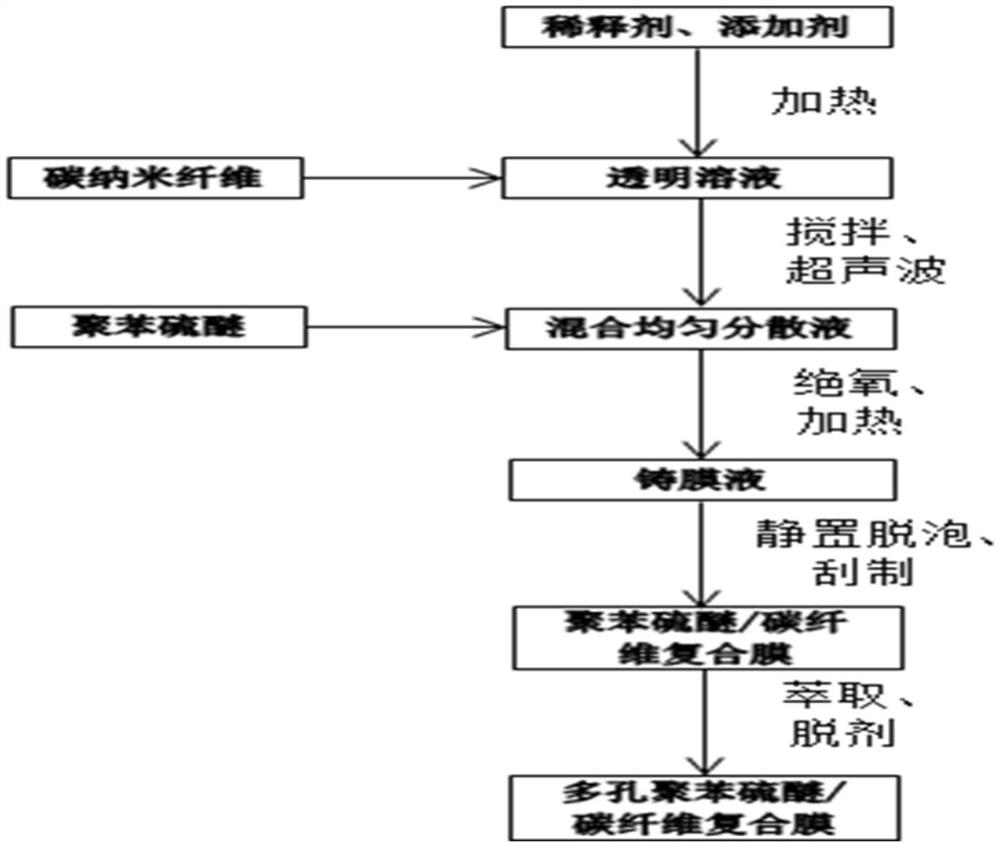

Polyphenylene sulfide/porous carbon nanofiber composite membrane and preparation method thereof

ActiveCN112337318AImprove separation efficiencySolve the problem of low separation efficiencySemi-permeable membranesMembranesIndustrial effluentPorous carbon

The invention relates to a polyphenylene sulfide / porous carbon nanofiber composite membrane and a preparation method thereof. The material composition, by percentage content, comprises 40-80% of a diluent; 10-1% of an additive; 10-1% of carbon nanofibers; and 40-18% of polyphenylene sulfide. The average pore diameter of the prepared composite membrane is 0.02-0.2 mu m. The polyphenylene sulfide / porous carbon nanofiber composite membrane is prepared by taking polyphenylene sulfide with acid and alkali resistance, high temperature resistance and solvent resistance as a base membrane material andadjusting the mass fractions of polyphenylene sulfide resin, the diluent, the additive and porous fluorinated, nitrified or sulfonated carbon nanofibers, and the polyphenylene sulfide / porous carbon nanofiber composite membrane is prepared through structure regulation and control. The separation efficiency of antibiotic macromolecules, dye molecules and heavy metals in industrial wastewater is greatly improved, the problem of low separation efficiency of a traditional polyphenylene sulfide membrane is solved, and the method has a wide application prospect in the field of industrial wastewatertreatment.

Owner:CHINA PETROLEUM & CHEM CORP

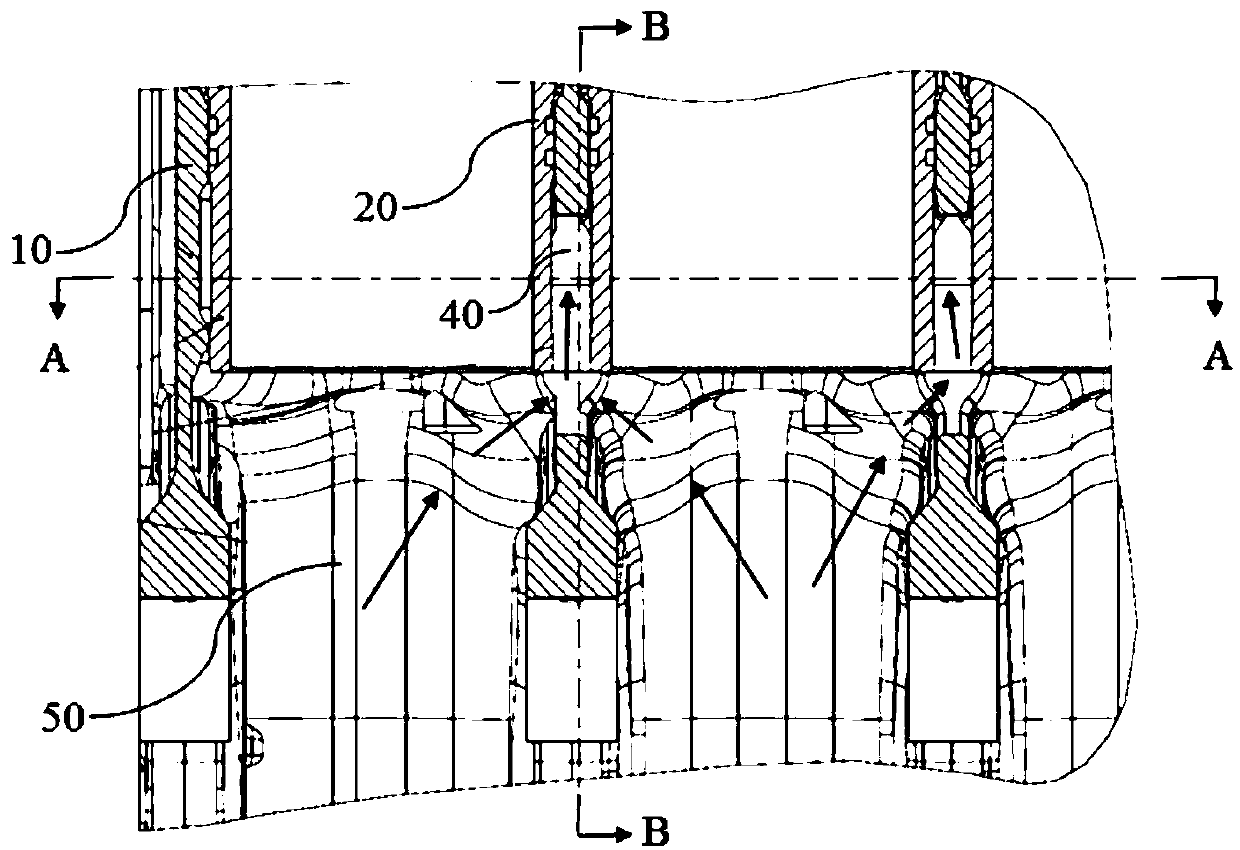

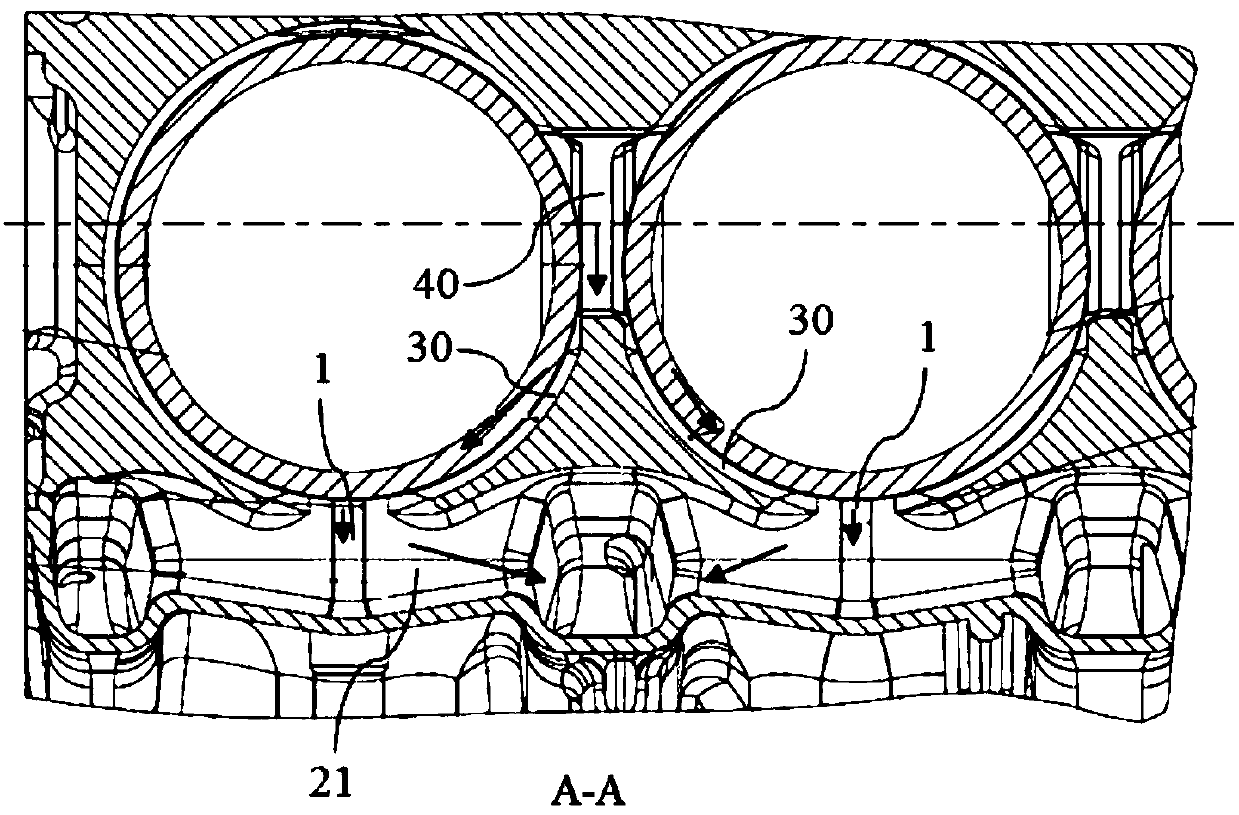

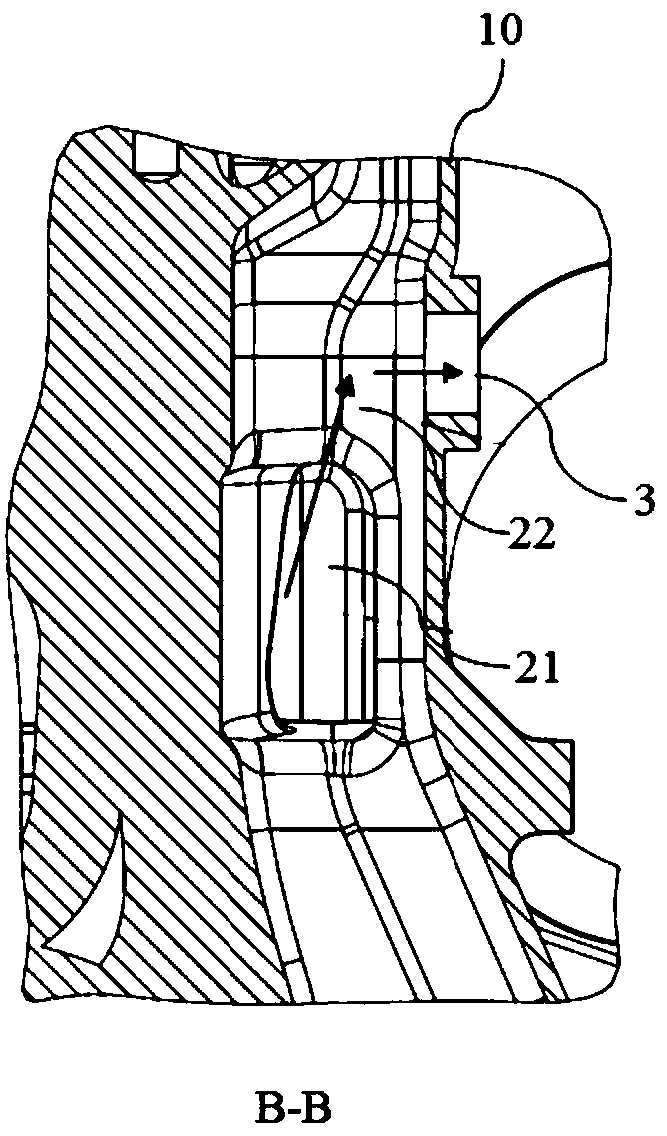

Gas taking structure of oil-gas separator and engine

ActiveCN108678835AAir intake position is highSolve the problem of low separation efficiencyMachines/enginesCrankcase ventillationEngineeringCrankcase

The invention provides a gas taking structure of an oil-gas separator and an engine. The gas taking structure is arranged on a cylinder body of the engine, the gas taking structure comprises an oil-gas inlet, a gas taking channel arranged in the cylinder body and a gas taking port, the gas taking channel comprises an oil-gas pre-separation cavity and an oil-gas rising cavity which are communicatedwith each other, the oil-gas inlet is arranged at an air inlet end of the oil-gas pre-separation cavity, a gas outlet end of the oil-gas pre-separation cavity is connected with an air inlet end of the oil-gas rising cavity, an air outlet end of the oil-gas rising cavity is connected with the gas taking port, and the gas taking port is arranged at an upper part of the cylinder body and connected with an air inlet of the oil-gas separator; the oil-gas in a crankcase can enter the oil-gas pre-separation cavity through the oil-gas inlet for oil and gas pre-separation, and the pre-separated oil-gas can rise to the gas taking port through the oil-gas rising cavity and enter the oil-gas separator through the gas taking port for oil-gas separation. According to the gas taking structure of the oil-gas separator and the engine of the invention, a pre-separation structure is integrated on the cylinder body, and the gas taking position is high, so that the oil content can be reduced, and the separation efficiency can be improved.

Owner:WEICHAI POWER CO LTD

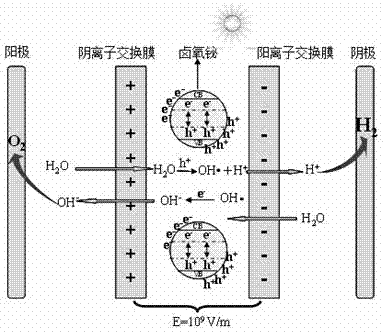

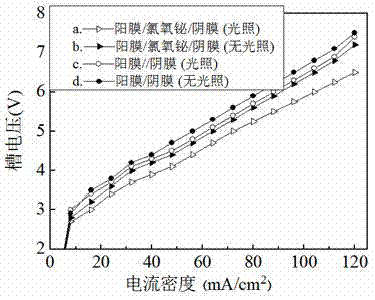

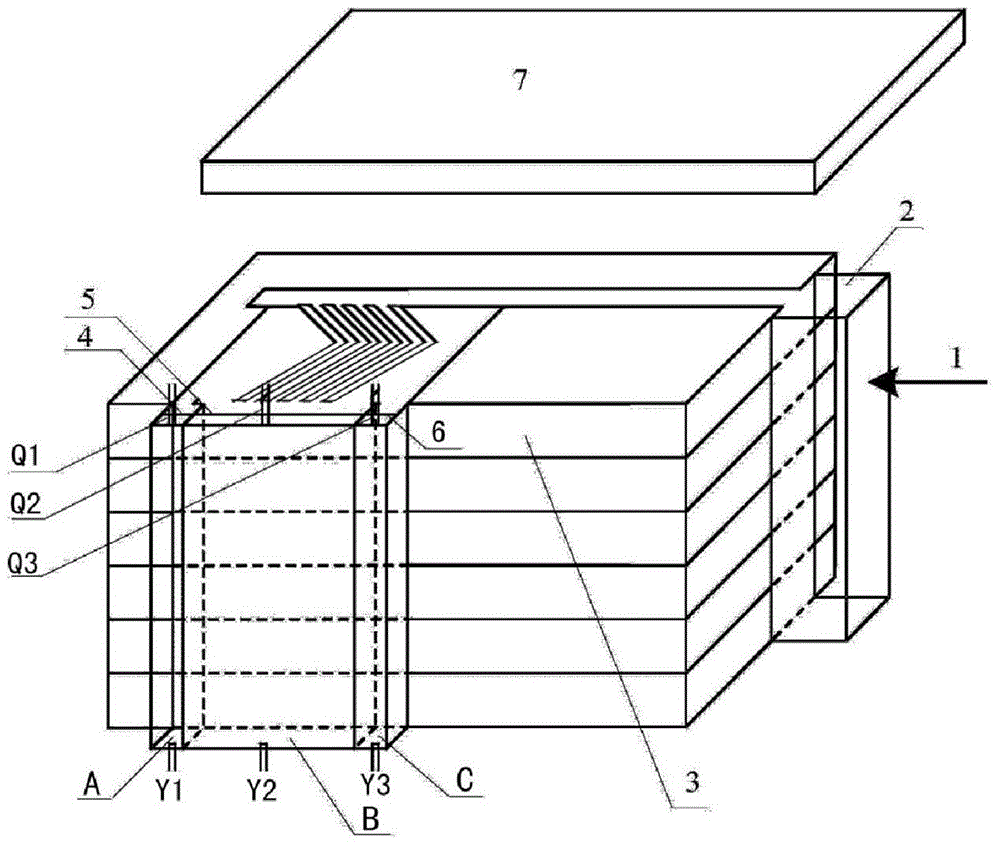

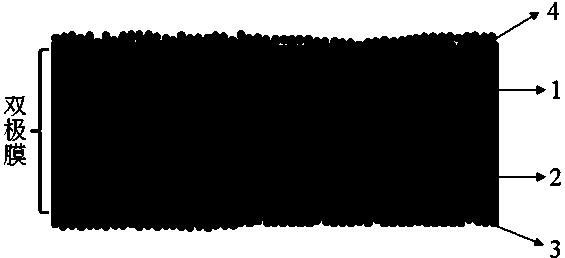

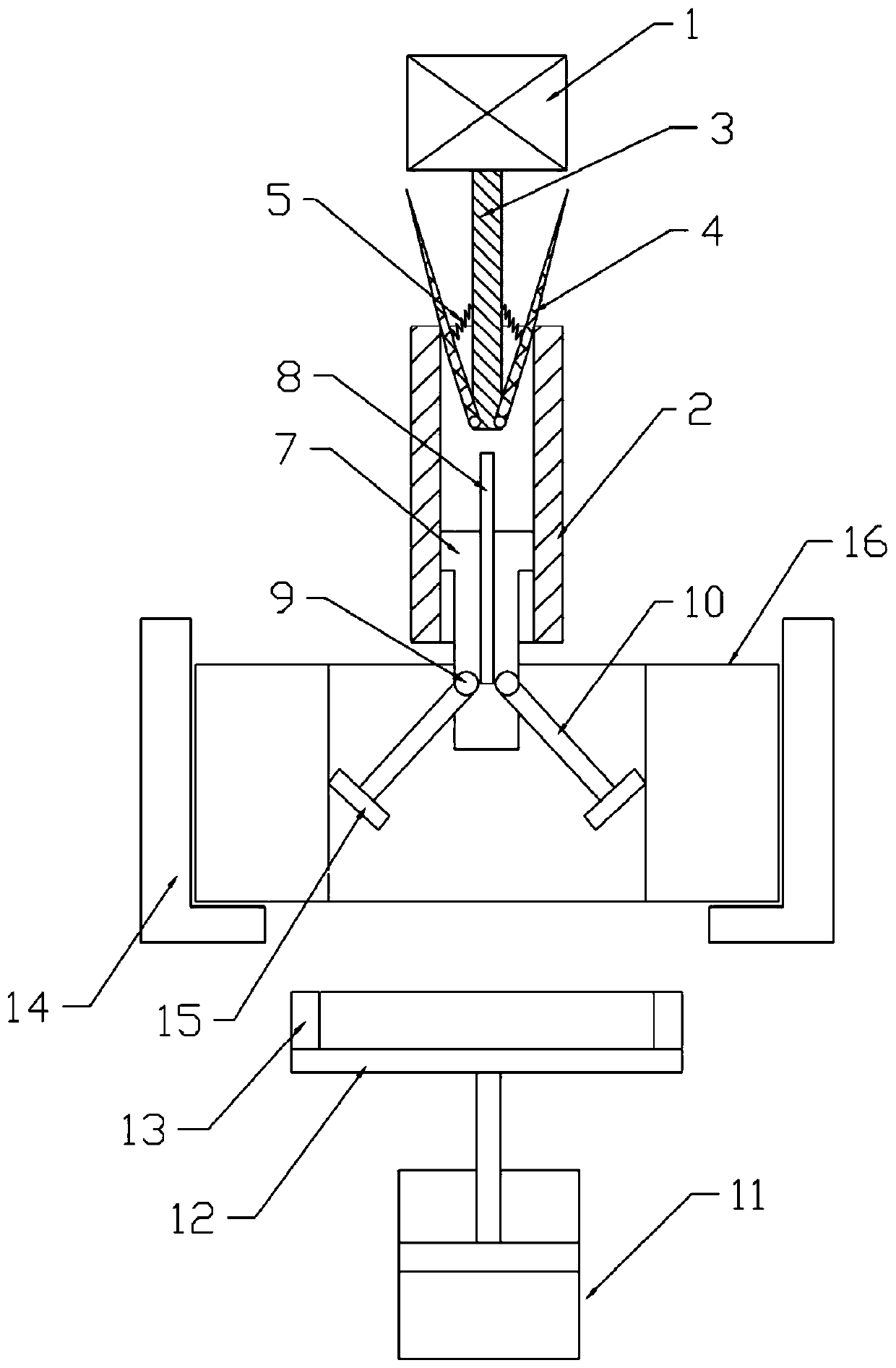

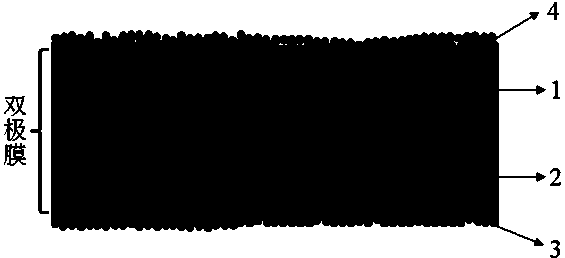

Application of a powder photocatalyst on the surface of a bipolar membrane in water splitting

ActiveCN107012475BEasy reunionSolve the problem of low separation efficiencyCellsElectrodesDecompositionElectrolyte

An application of a bipolar film surface powder state photocatalyst in water splitting, the application is based on a cation exchange membrane with a surface-loaded P-type semiconductor photocatalyst powder and an anion-exchange membrane with a surface-loaded N-type semiconductor photocatalyst powder as bipolar film, and constitute the cathode chamber and the anode chamber diaphragm, the P-type semiconductor photocatalyst powder material is used as the cathode, and the N-type semiconductor photocatalyst powder material is used as the anode. A xenon lamp was used as the light source, and the photocatalytic water splitting hydrogen production was continuously carried out under the action of an applied voltage of 0.5-2.0 V. In the present invention, the catalyst in powder state is attached to both sides of the bipolar membrane for photoelectric catalytic water splitting to produce hydrogen. The voltage and hydrogen production efficiency remain basically unchanged, realizing the efficient and continuous operation of semiconductor powder state photocatalyst to decompose water to produce hydrogen.

Owner:TAIYUAN NORMAL UNIV

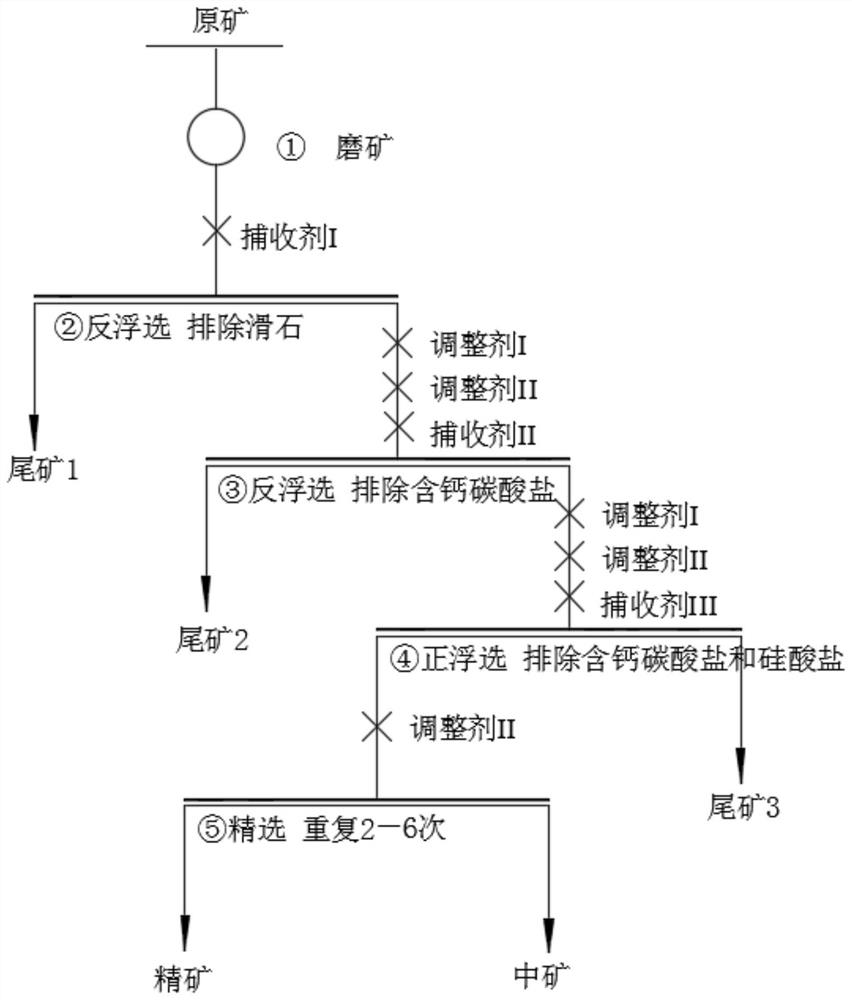

Method for refining magnesite

The invention relates to a method for refining magnesite, and belongs to the technical field of magnesite mineral processing. The method comprises the steps: firstly removing talc silicate minerals through reverse flotation; then removing most of calcium-containing carbonate gangue through reverse flotation; performing direct flotation to remove silicate minerals and calcium-containing carbonate minerals; and finally, obtaining magnesite concentrate through concentration. According to the method, a reverse-reverse-forward flotation method is adopted, and reagents in the flotation process are combined so that the floatability difference between the magnesite and gangue minerals is increased, and the problem of separation of calcium and magnesium in the magnesite refining process is solved.The low-carbon organic acid and the inorganic strong acid are combined, the sorting property of magnesium and calcium is effectively improved through directional complexing of organic acid radical ions, and mineral purification is achieved through the anion collecting agent. The method has the advantages that magnesite raw ore with poor quality can be used for obtaining high-quality concentrate products, the boundary grade of the selected raw ore is increased, and comprehensive utilization of mineral resources is facilitated.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

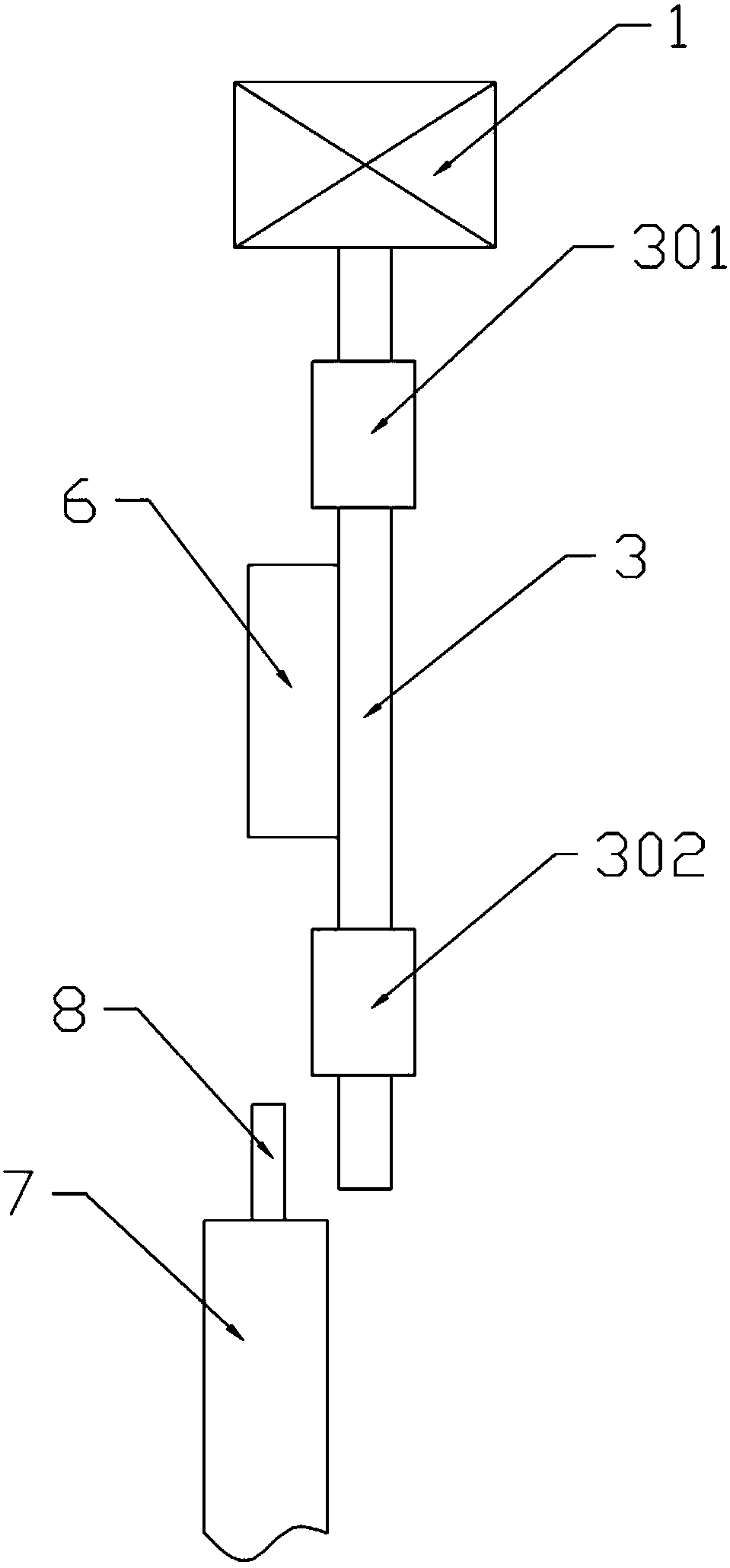

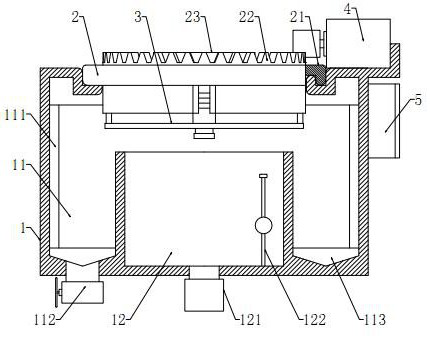

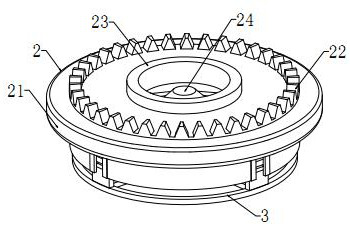

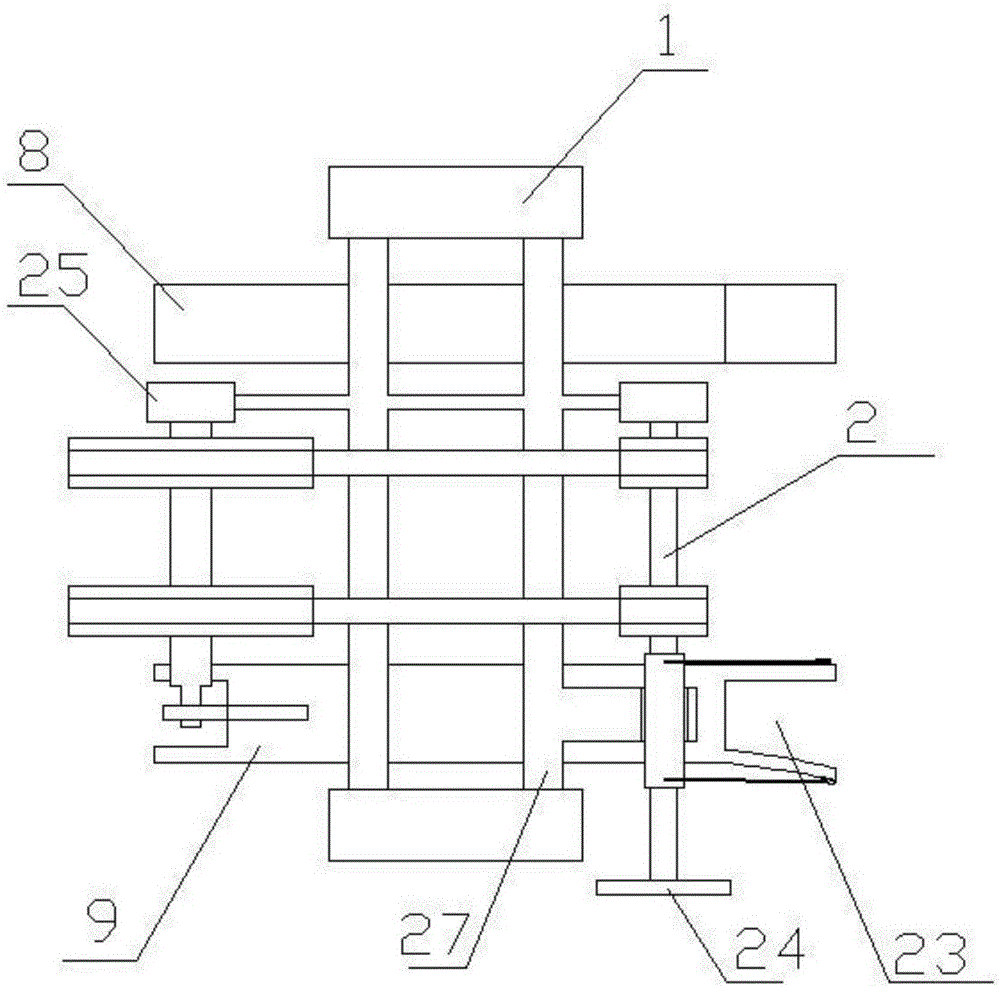

Small medical syringe rapid destruction machine

PendingCN112275787AIncomplete solution to fusingFix the needleSolid waste disposalRadiationUv disinfectionEngineering

The invention discloses a small medical syringe rapid destruction machine. The mall medical syringe rapid destruction machine comprises a supporting assembly, a clamping assembly, a heating assembly and a disinfection assembly. The supporting assembly comprises a box body, a top cover, a first partition plate, a second partition plate and a bottom plate. The clamping assembly comprises two supporting seats, a clamping rod, an elastic piece, a fixing head and a character grinding mechanism, the clamping rod is installed between the two supporting seats in a sliding manner, the elastic piece isinstalled on the outer side of the clamping rod in a sleeving manner, and the fixing head is installed at one end of the clamping rod. The heating assembly comprises a variable-frequency heating controller, an electromagnetic heating coil and two heat insulation bases, the variable-frequency heating controller is installed on the upper wall of the second partition plate, and the electromagnetic heating coil is electrically connected with the variable-frequency heating controller. The disinfection assembly comprises a drawer and an ultraviolet disinfection lamp, the drawer is slidably installedon the upper wall of the bottom plate, and the ultraviolet disinfection lamp is installed in the drawer. By means of the small medical syringe rapid destruction machine, separation and destruction ofdisposable syringes are effectively achieved, and unified collection and disinfection of the syringes are also achieved.

Owner:TAIZHOU POLYTECHNIC COLLEGE

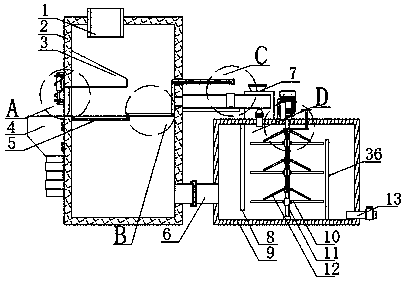

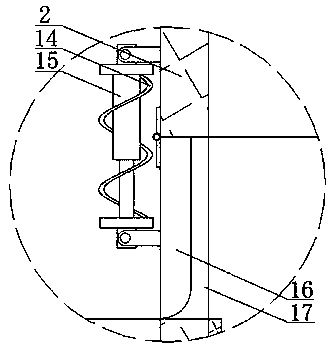

A kind of method and its equipment of synthesizing methyl isobutyl ketone by acetone two-step method

ActiveCN108002995BReduce the problem of high DAA contentReduce generationOrganic compound preparationEnergy inputMethyl isobutyl ketoneFluid phase

The invention discloses a method and equipment for synthesizing methyl isobutyl ketone by a two-step method from acetone. The method comprises: a. the raw material acetone is condensed and dehydrated in a catalytic rectification tower to generate DAA and MSO, and is fed to the side line of the catalytic rectification tower Extract products rich in MSO and water; b. The DAA-containing material is extracted from the side line of the catalytic rectification tower and enters the DAA decomposition reactor. The DAA in the material is converted into acetone and MSO, and the product is flash separated to obtain acetone-rich gas phase and The liquid phase containing MSO and water is recycled back to the tower respectively; c, the liquid phase product described in step a is cooled and phase-separated to obtain an organic phase rich in MSO and an aqueous phase containing a small amount of organic matter, and the aqueous phase enters the recovery tower to recover organic matter; d 1. The organic phase described in step c is hydrogenated to generate MIBK, and the hydrogen gas is recovered by flash evaporation and then enters the MIBK refining tower, and the MIBK product is extracted from the side line. The whole process conversion rate of acetone in the invention reaches 99.0%, and the purity of the product MIBK can reach 99.5%.

Owner:长成新能股份有限公司 +1

A method for separating and culturing rabbit adipose stem cells

ActiveCN104818246BDigest thoroughlyImprove separation efficiencySkeletal/connective tissue cellsStem cell cultureCryopreservation

The invention discloses a method for separating and culturing rabbit fat stem cells. It includes the following steps: (1) aseptically obtain rabbit adipose tissue; (2) prepare a small piece of fat tissue; (3) digest the adipose tissue with trypsin, and separate the upper layer solution and the lower layer precipitate; (4) the upper layer solution Digest by time gradient method; (5) collect adipose stem cells, mix with adipose stem cell culture medium, inoculate and culture; (6) in vitro culture of adipose stem cells; (7) detect and freeze. In the cell separation method, the tissue digestion is not complete enough, and the cell separation efficiency is low. The separation method of adipose stem cells is optimized, which makes the adipose tissue digestion more thorough, improves the cell separation efficiency, and thus provides a better source of adipose stem cells.

Owner:深圳尤尼智康医疗科技有限公司

Split type polluted waste water treatment equipment

InactiveCN110357315ARapid solid-liquid separationEasy to transportTreatment involving filtrationMultistage water/sewage treatmentWater treatmentWastewater disposal

The invention discloses split type polluted waste water treatment equipment. The split type polluted waste water treatment equipment comprises a casing; a fixed block and a first sieve plate are fixedon the side wall of one inner end of the casing sequentially from top to bottom; a sliding groove is formed at the upper end of the first sieve plate; a sliding block is arranged in the sliding groove; a second sieve plate is fixed at the upper end of the sliding block; a moving groove is formed at the upper end of the second sieve plate; a moving block is arranged in the moving groove; a baffleis fixed at the upper end of the moving block; an oil cylinder is arranged on one side of the casing in a run-through way; the tail end of a piston rod of the oil cylinder runs through the casing andis fixed on one side of the baffle; and a closing mechanism is arranged on the baffle. The split type polluted waste water treatment equipment can solve the problem of low separation efficiency of solid garbage well, can separate solid and liquid rapidly, can guarantee solid garbage separation quality, can treat impurities of waste water well and can improve the waste water treatment quality.

Owner:山东格润内泽姆环保科技有限公司

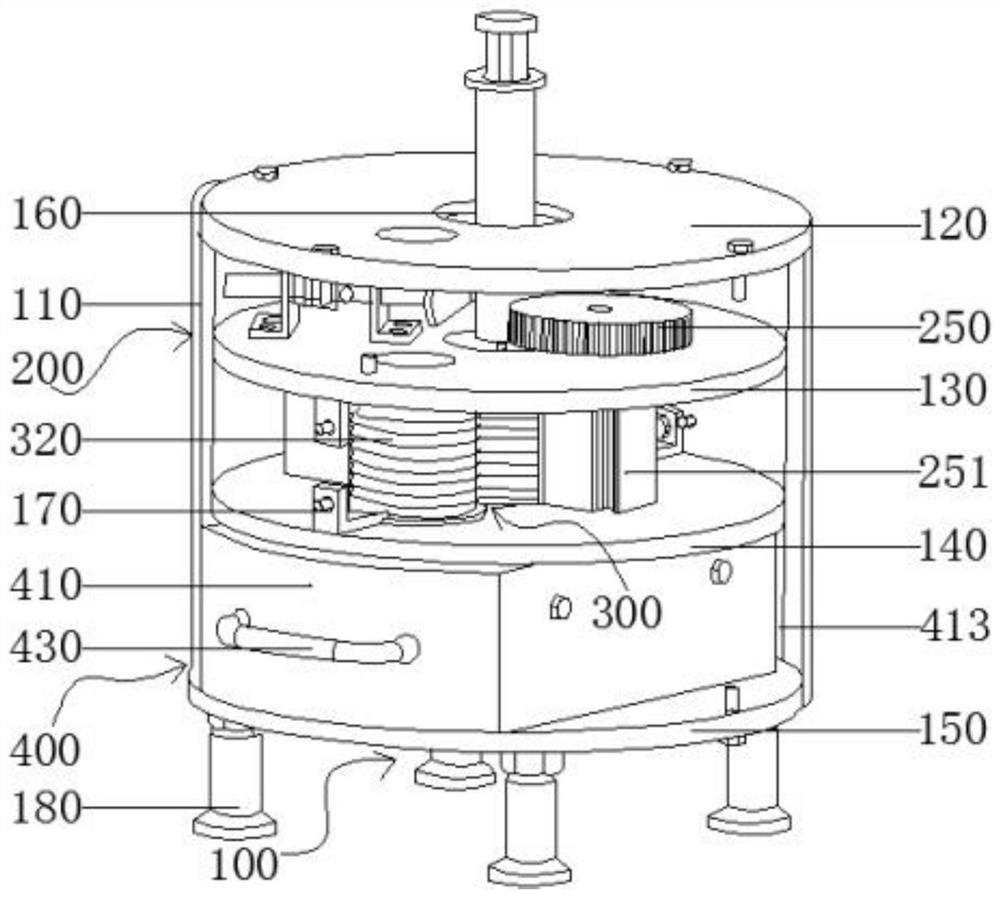

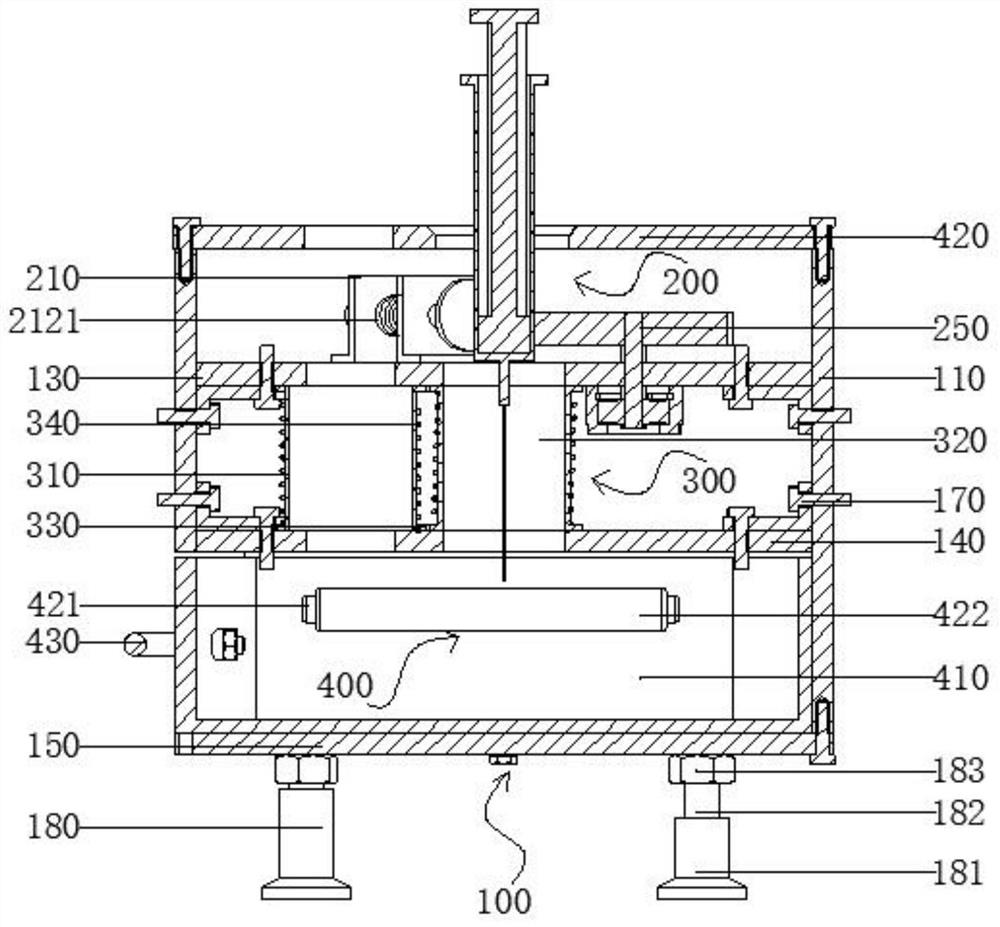

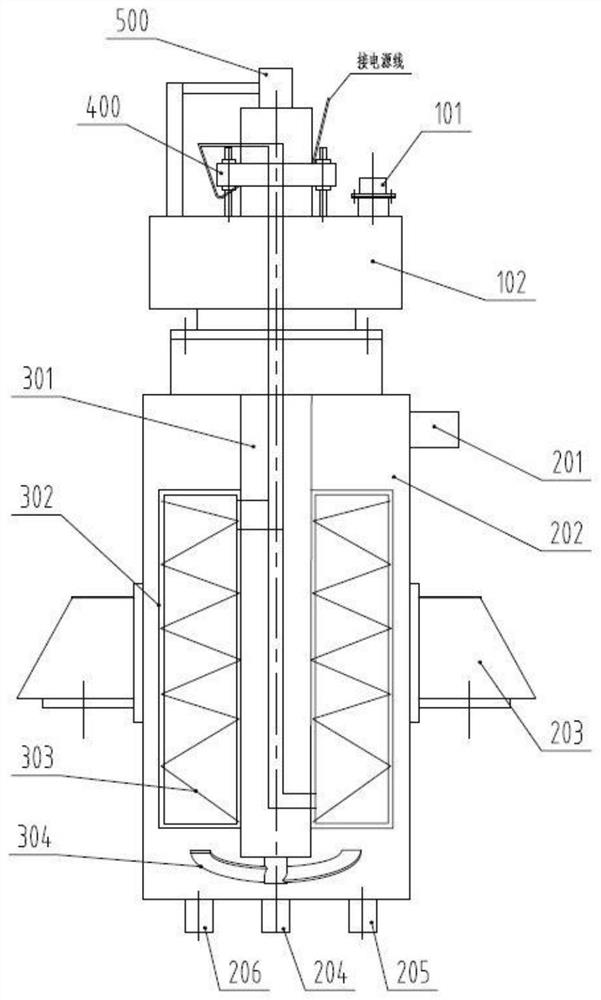

Magnetic separator with controllable magnetic force and for oil-water separation, and oil-water separation method thereof

PendingCN113620394ASolve the problem of low separation efficiencyMagnetic field controllableFatty/oily/floating substances removal devicesWater/sewage treatment by magnetic/electric fieldsMagnetic tension forceMagnetic separator

The invention discloses a magnetic separator with controllable magnetic force and for oil-water separation, and an oil-water separation method thereof. The magnetic separator comprises a shell provided with a feeding port and a discharging port and a rotating mechanism installed in the shell, wherein the rotating mechanism comprises a rotating shaft and blades installed in the circumferential direction of the rotating shaft, and magnetic-force-adjustable electromagnetic coils are installed in the blades. According to the invention, the electromagnetic coils are arranged in the blades and connected with a power source, and the magnetic force of the electromagnetic coils is controlled through the power source, so the surfaces of the blades are provided with magnetic fields of different sizes so as to realize attraction of oil and magnetic substances respectively; the oil and magnetic substances are released in sequence and discharged through a discharging port, so separation and collection of water, oil and the magnetic substances are completed; and the problem that separation efficiency is not high due to the fact that attraction equipment needs to be replaced when different substances are separated through an existing magnetic separator is solved.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

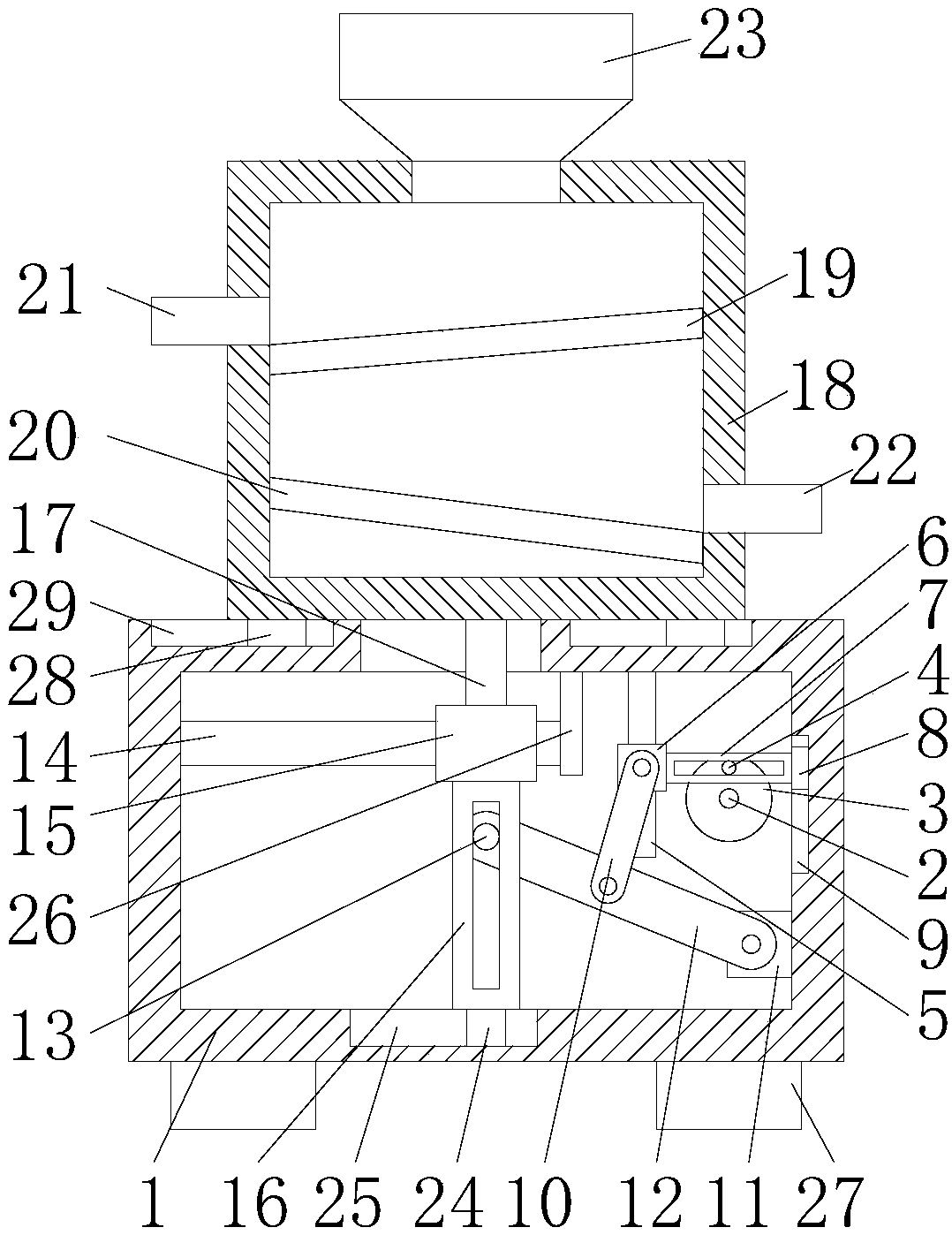

Crystal separation device for high-purity oxalic acid in dyeing and finishing auxiliary for textile

PendingCN108325827ASolve the problem of low separation efficiencyImprove practicalitySievingScreeningEngineeringOxalic acid

The invention discloses a crystal separation device for high-purity oxalic acid in a dyeing and finishing auxiliary for textile. The crystal separation device comprises a base box. A motor is fixedlyconnected to the right side of the back face of the inner wall of the base box. The output end of the motor is fixedly connected with a disk. A transmission bar is fixedly connected to the top of thefront side of the disk. According to the crystal separation device for the high-purity oxalic acid in the dyeing and finishing auxiliary for textile, the base box, the motor, the disk, the transmission bar, a first unthreaded rod, a first sliding ring, a transmission frame, a first sliding block, a first sliding groove, a connecting plate, a fixing block, a rotary plate, a transmission column, a second unthreaded rod, a second sliding ring, a movable frame, a movable rod, a separation box, a screen, a partition plate, a first discharging pipe, a second discharging pipe and a hopper are used incooperation, so that the problem of low separation efficiency of an existing crystal separation device is solved. The crystal separation device for the high-purity oxalic acid in the dyeing and finishing auxiliary for textile has the advantage of efficient separation, saves a large quantity of time for users and can be used by the users conveniently, and the practicability of the crystal separation device is improved.

Owner:YANCHENG INST OF IND TECH

Petroleum coking wastewater treatment device

InactiveCN111908698AEfficient and convenient EfficiencyImprove efficiencyFatty/oily/floating substances removal devicesWater contaminantsOil separationWater storage tank

The invention provides a petroleum coking wastewater treatment device, and relates to the field of petroleum coking wastewater treatment. The petroleum coking wastewater treatment device comprises a water storage tank, an oil-water separation device, an ammonia nitrogen reaction tank and a purification tank, wherein the water storage tank is fixedly mounted on the right side of a base, and a cooling layer is arranged on the inner wall of the water storage tank. According to the petroleum coking wastewater treatment device, through the oil-water separation device arranged on the base, wastewater is heated by the heating box, oil is activated to float upwards to be layered with the wastewater, then deoiled wastewater is discharged through a wastewater discharge port by virtue of an isolationplate arranged on the left side, and dirty oil is left in the water-oil separation cavity and is extracted by virtue of an oil skimmer; the problem that an existing petroleum wastewater device is nothigh in dirty oil separation efficiency is effectively solved, the ammonia nitrogen neutralization tank and the air pump are arranged in the ammonia nitrogen neutralization tank, a proper alkaline solution is added, ammonia nitrogen elements can generate ammonia gas more quickly when making contact with air, and the ammonia nitrogen removal efficiency is improved efficiently, conveniently and rapidly.

Owner:岳文智

Bead wire separation device

The invention relates to a tire bead wire separating device, and belongs to the technical field of solid waste treatment. The tire bead wire separating device comprises a machine frame, wherein a motor, a fixing tube and a clamping device are installed on the machine frame from top to bottom, the motor is connected with a telescopic rod, and the telescopic rod is provided with a first telescopic section, a second telescopic section and cutters from top to bottom; the cutters are hinged to the telescopic rod, springs are connected between the cutters and the telescopic rod, and a push rod is connected to the side wall of the telescopic rod; a support rod is arranged in the fixing tube, the support rod is connected with a rack in a sliding mode, two gears are rotationally connected to the support rod, the gears are meshed with the rack, and the gears are coaxially connected with supporting bars; and a pulling device is arranged below the clamping device, the pulling device comprises an air cylinder, a working table is connected to the air cylinder, and electromagnets are connected to the working table. According to the technical scheme, a waste tire does not have relatively large deformation in the pulling process, furthermore, the whole pulling process is mechanical, the separating efficiency is high, the effect is good, and the practicability is high.

Owner:重庆九橡化大橡胶科技有限责任公司

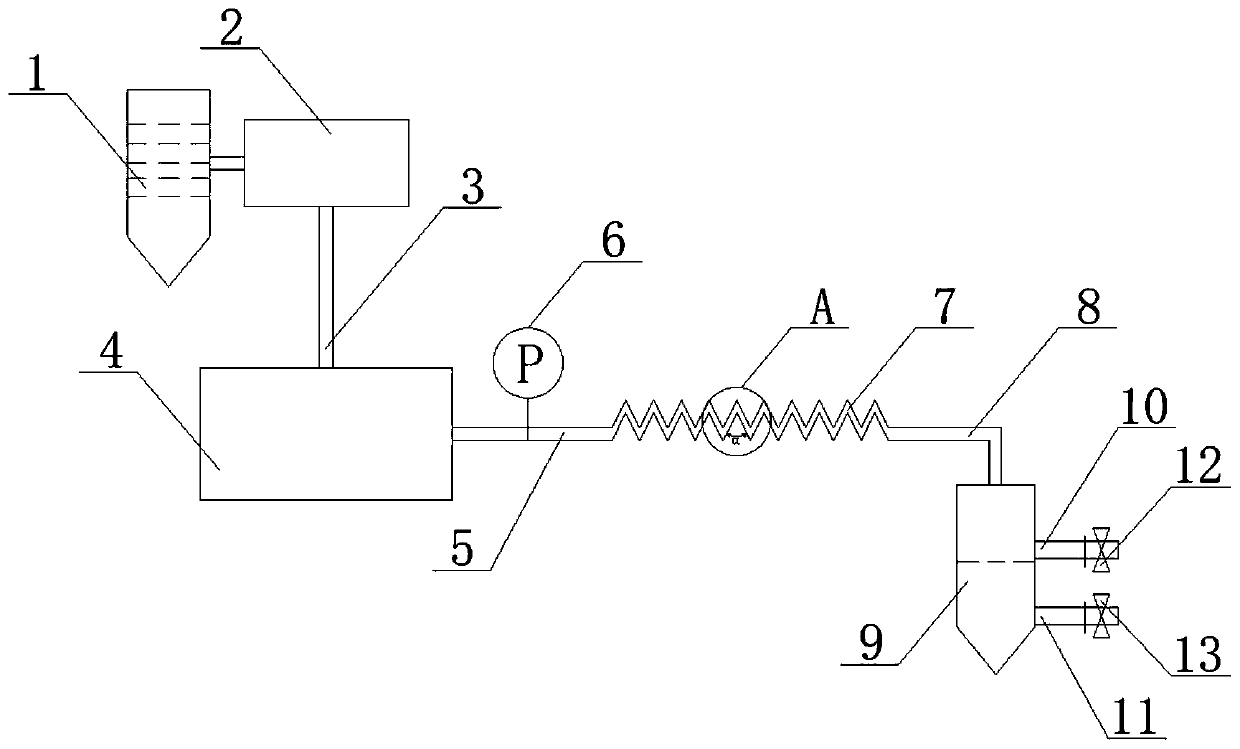

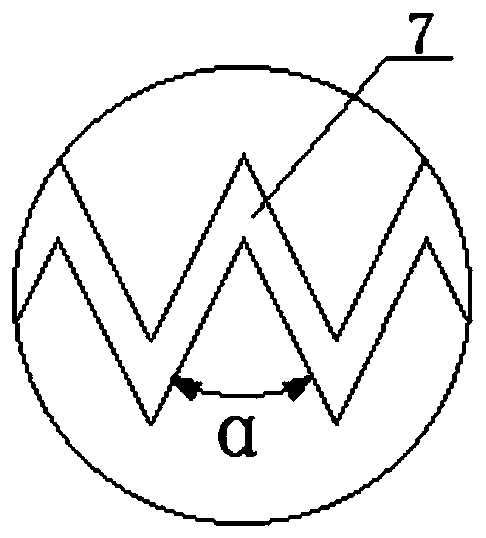

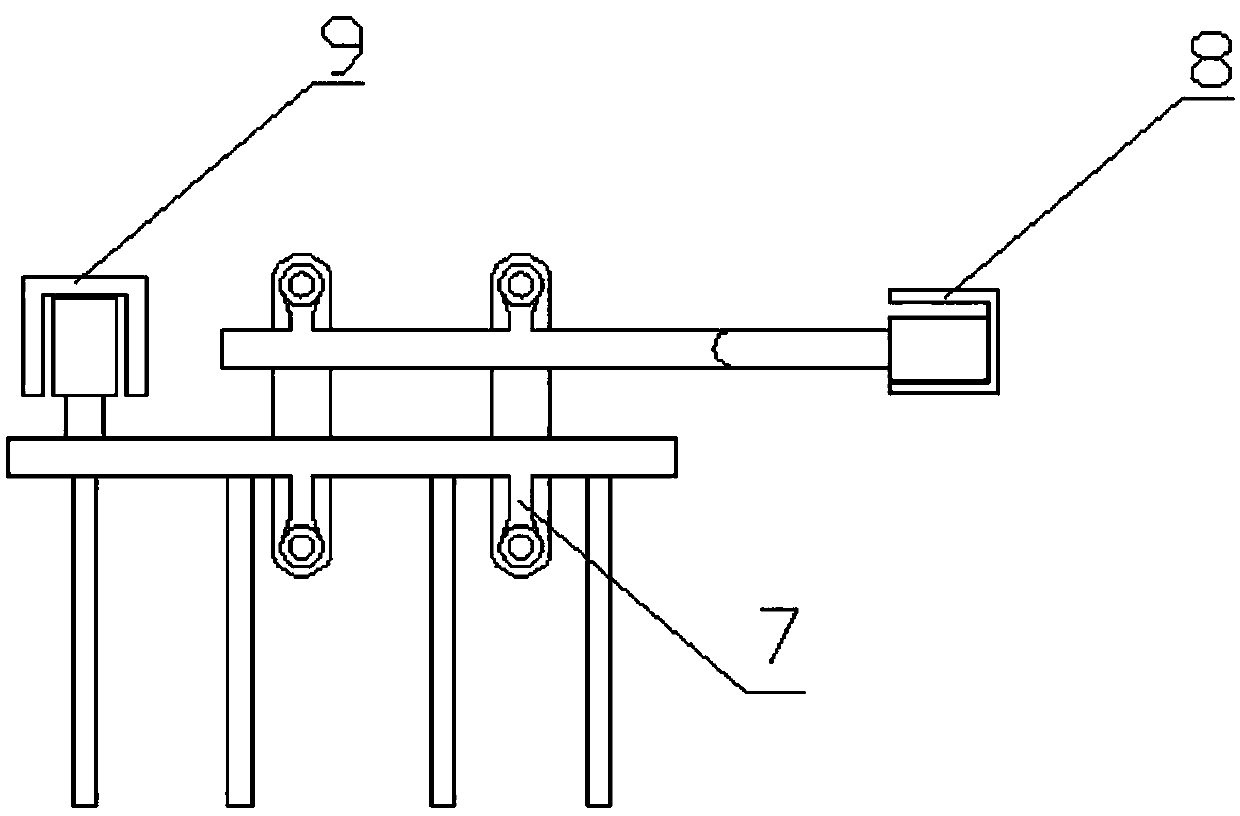

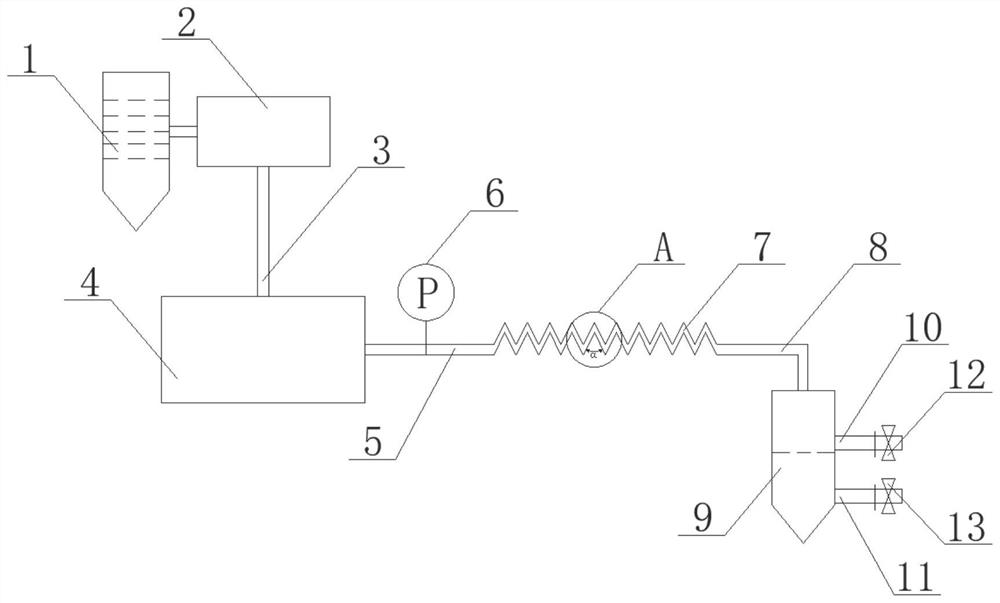

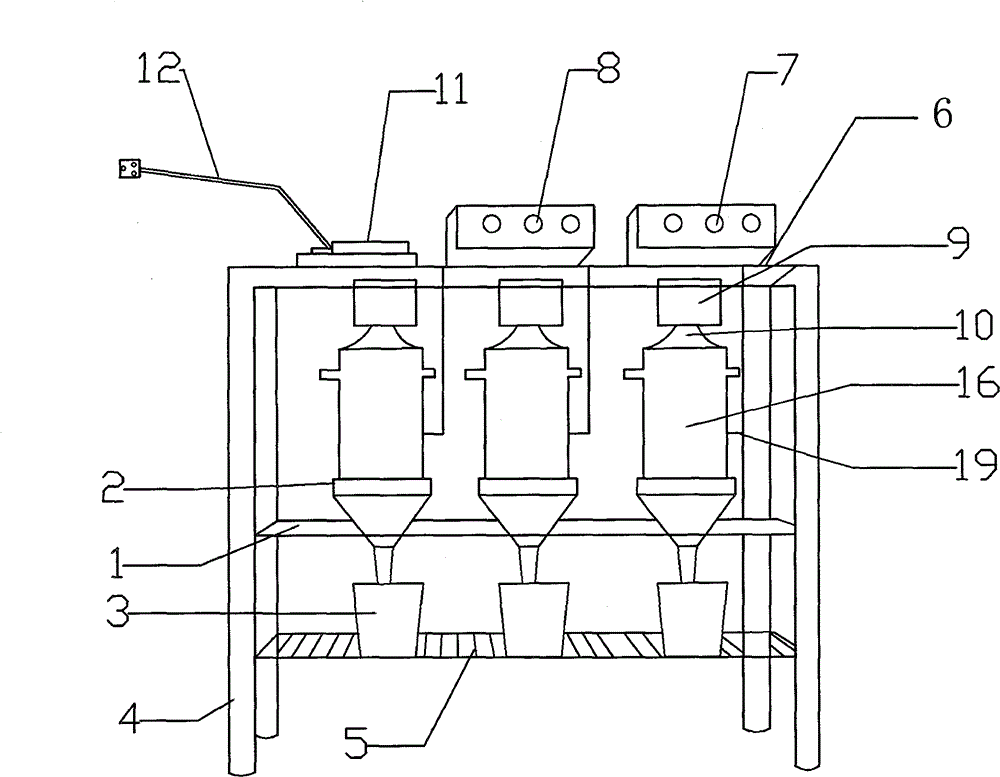

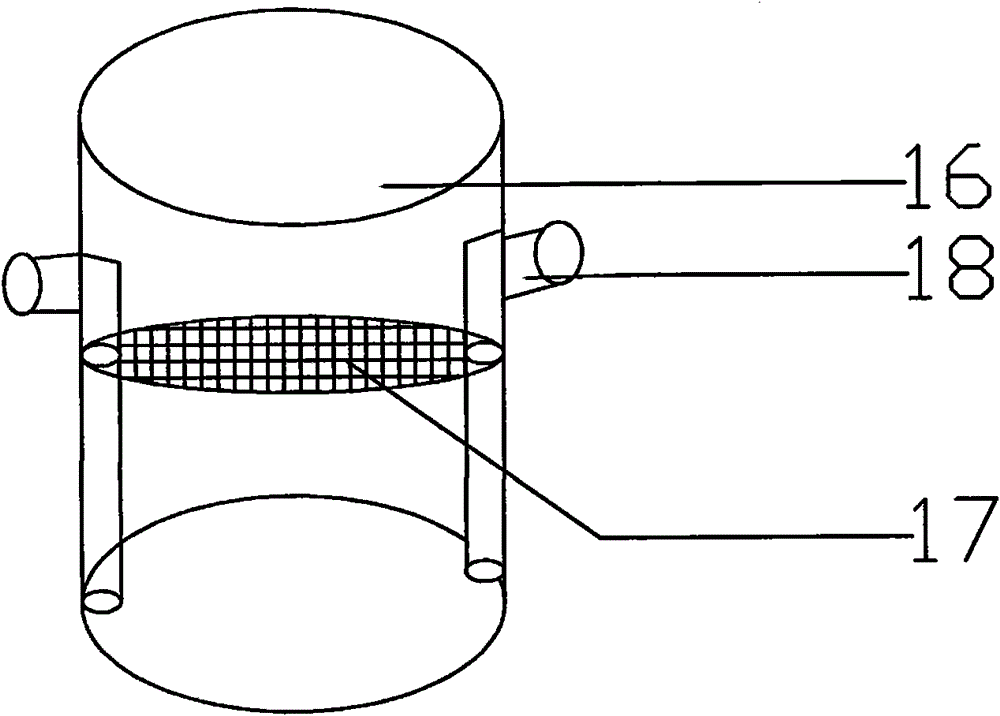

Strong turbulence shearing micro-channel oil-water separation device

The invention provides a strong turbulence shearing micro-channel oil-water separation device. The device comprises an oily wastewater storage tank (1), an oil-water delivery pump (2), an oil-water delivery pipe (3), a pneumatic liquid booster pump (4), a connecting pipe (5), a micro-channel (7), a liquid collecting pipe (8) and an oil-water separation tank (9) which are sequentially connected inseries, a pressure gauge (6) is arranged on the connecting pipe (5), an oil-phase liquid outlet (10) and a water-phase liquid outlet (11) are respectively formed in the oil-water separation tank (9),an oil-phase switching valve (12) is arranged at the front end of the oil-phase liquid outlet (10), and a water-phase switching valve (13) is arranged at the front end of the water-phase liquid outlet(11). The device disclosed by the invention has the advantages of small equipment investment, high oil-water separation efficiency and capability of realizing continuous operation in the purificationprocess of oily sewage and the like, and can be widely applied to efficient purification treatment on various oily and dusty wastewater.

Owner:SOUTHEAST UNIV +1

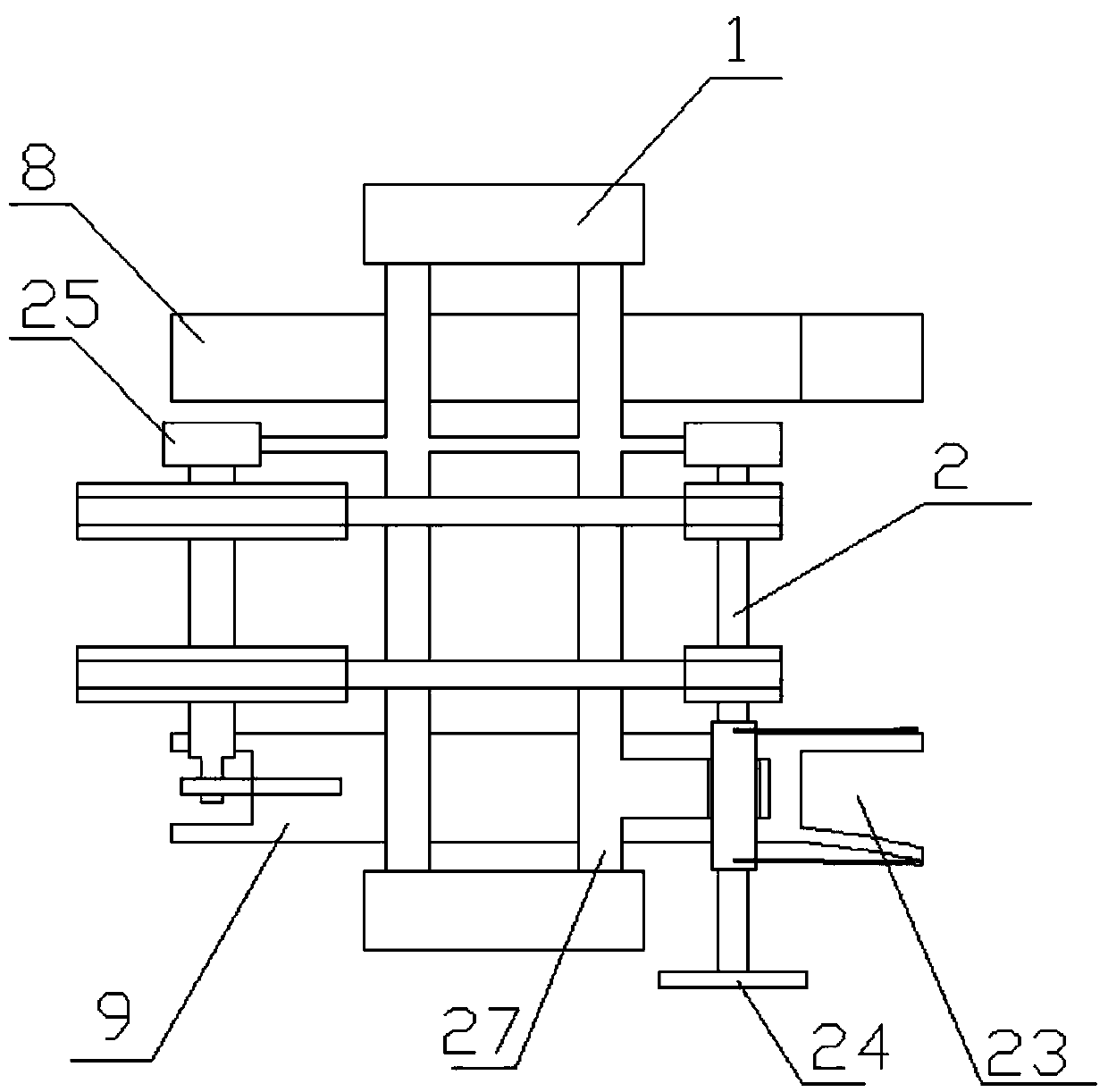

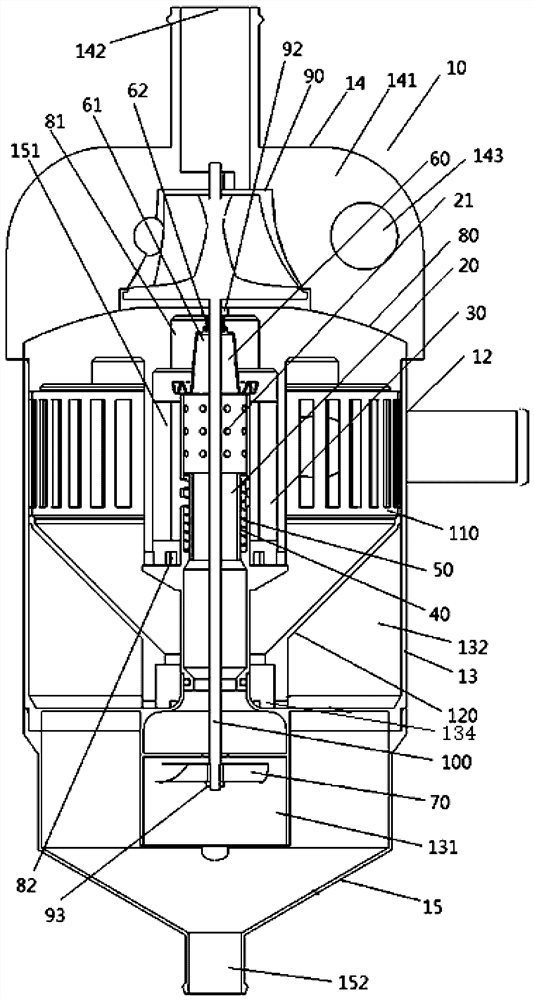

Environment-friendly sewage residue-liquid separation treatment equipment for concrete

ActiveCN111804021ASolve the problem of low separation efficiencyReasonable structureCentrifugal force sediment separationHeating arrangementSewageElectromagnetic valve

The invention discloses environment-friendly sewage residue-liquid separation treatment equipment for concrete. The equipment comprises a separation barrel, a separation turntable, a switch control mechanism, a power device and a controller. A wastewater and aggregate mixture is injected into the separation turntable, the power device drives the separation turntable to rotate to separate aggregates in the wastewater, a wastewater outlet is opened through the switch control mechanism to discharge wastewater into an inner barrel, then an aggregate outlet is opened through the switch control mechanism to discharge aggregate, a liquid level meter in the inner barrel detects the liquid level of the wastewater, an electromagnetic valve is opened to empty the wastewater when the inner barrel is about to be full, and an electric heating plate heats and dries the aggregates. The environment-friendly sewage residue-liquid separation treatment equipment for concrete is reasonable in structure, has the advantages of convenient use, high efficiency, no pollution and the like, and effectively solves the problem that an existing concrete mixer is low in sewage residue-liquid separation treatmentefficiency.

Owner:广州初曲科技有限公司

Method for purifying high-purity hydrogen or high-purity chlorosilane with phosphorus-containing impurities

ActiveCN106517094BSolve the problem of limited removal abilitySolve the problem of decreased adsorption capacityHydrogen separationHalogenated silanesMolecular sieveCombinatorial chemistry

The invention discloses a method for purifying high-purity hydrogen or high-purity chlorosilane with phosphorus-containing impurities, comprising the following steps: heating the high-purity hydrogen with phosphorus-containing impurities to 500-800°C, and reacting the phosphorus-containing impurities in the high-purity hydrogen with hydrogen Generate phosphine, and then adsorb the phosphine through molecular sieves to obtain purified high-purity hydrogen. The phosphorus-containing impurities in the high-purity hydrogen containing phosphorus impurities are converted into phosphine by heating, so that all kinds of phosphorus-containing impurities are reduced and reacted to form the same substance phosphine, because the molecular sieve has a large impact on the gas passing through it. Selective adsorption of phosphine, thereby improving the adsorption capacity of phosphine in high-purity hydrogen with phosphorus impurities, thus greatly improving the purity of purified high-purity hydrogen, and further improving the production of purified high-purity hydrogen as raw materials The quality of the polysilicon reduces the impurity content in the polysilicon.

Owner:XINTE ENERGY

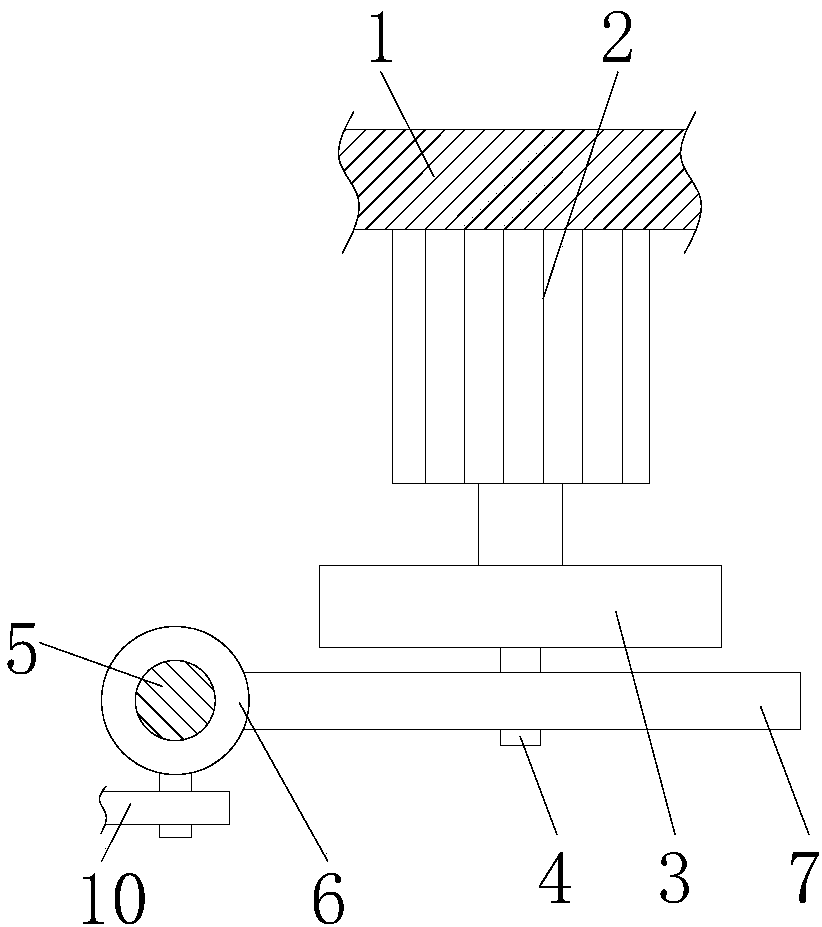

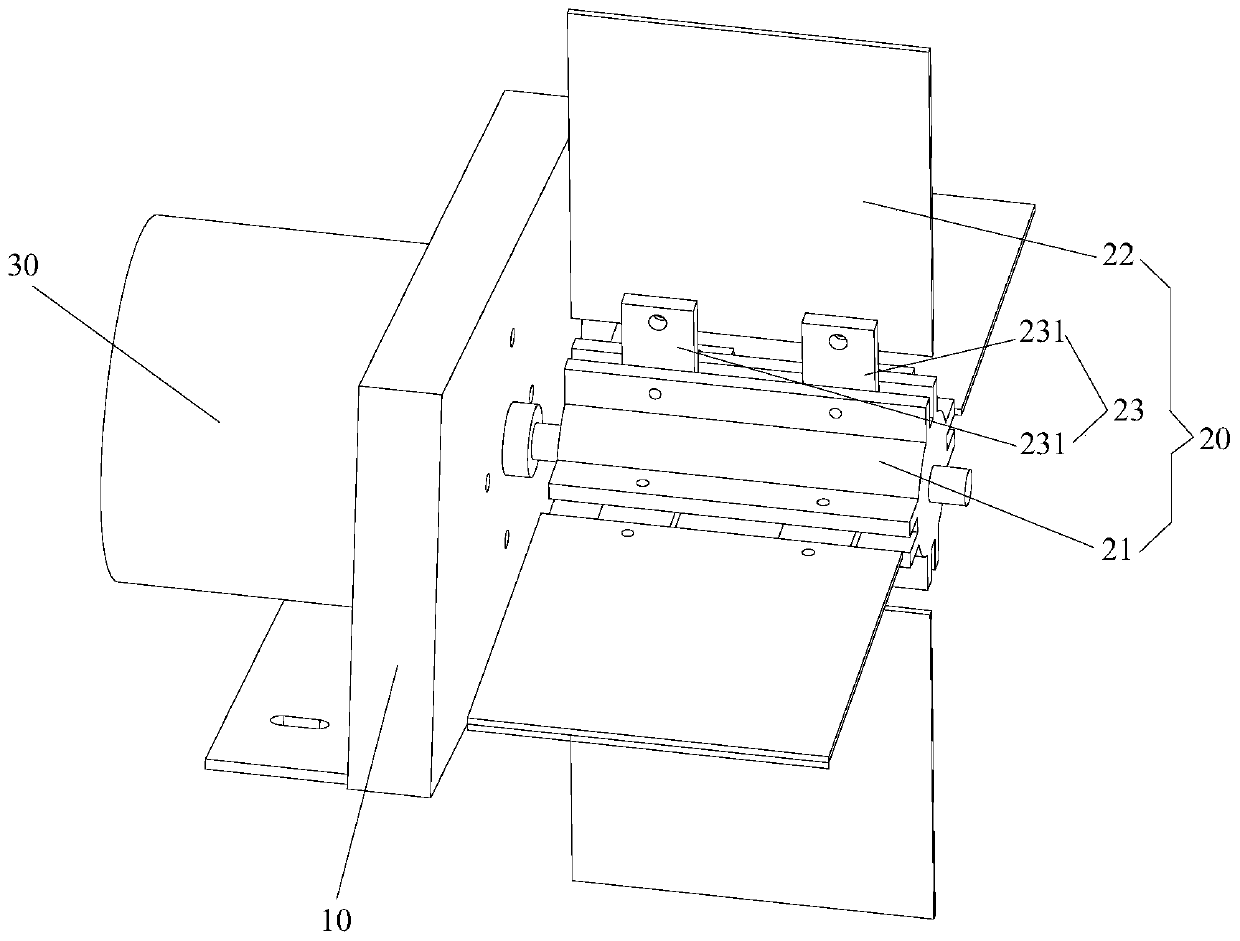

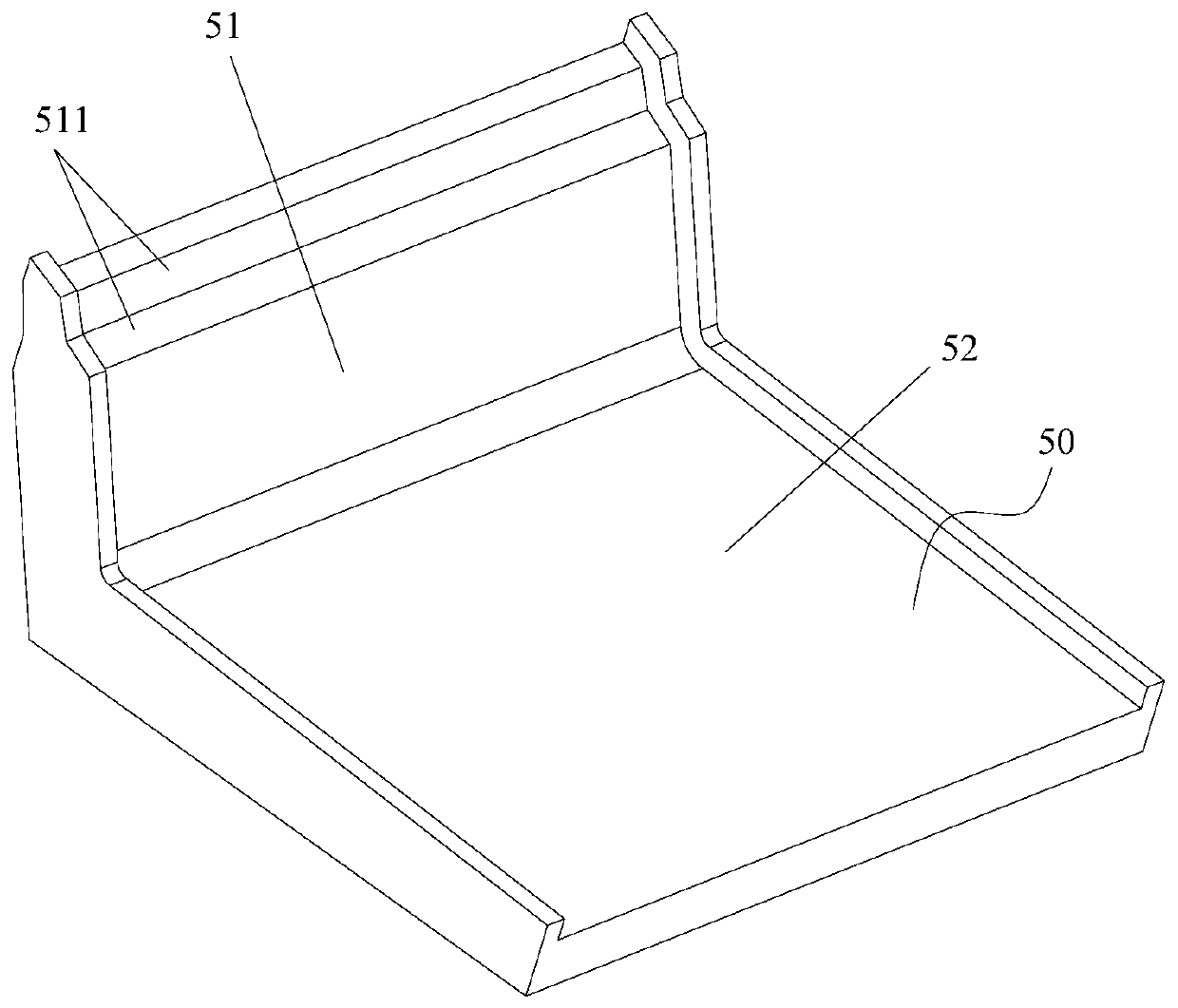

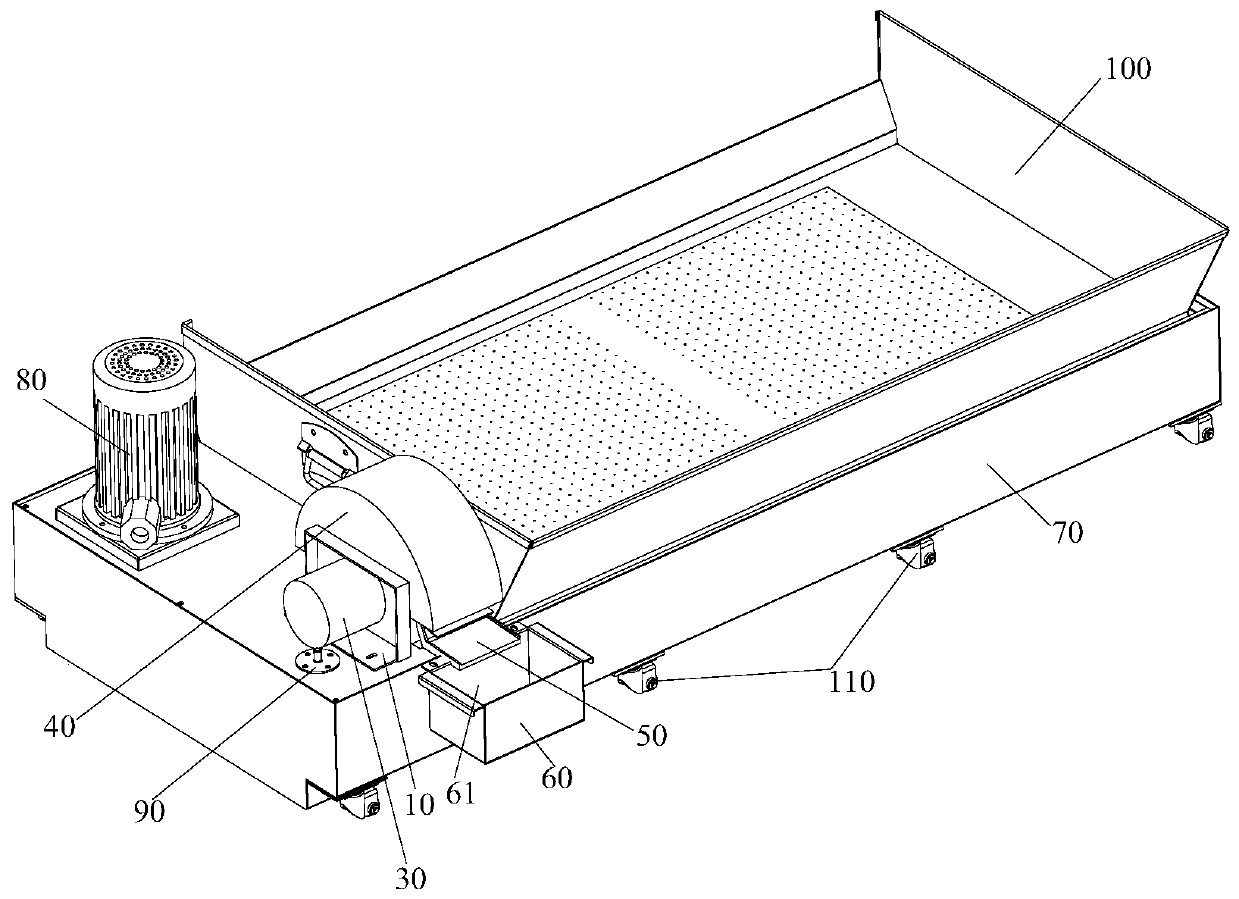

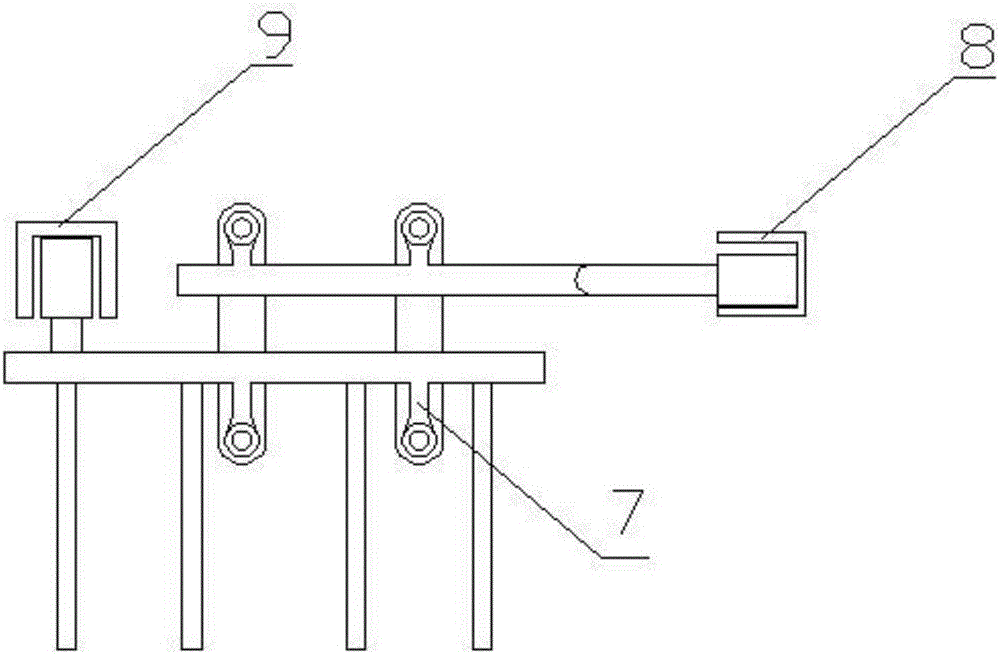

A kind of loosening device of separating sieve

InactiveCN106717592BSolve the problem of low separation efficiencyImprove separation efficiencyThreshersDrive shaftPlane parallel

The invention discloses a loosening device of a separating screen. The loosening device comprises a supporting frame, wherein a driving shaft and a driven shaft are arranged on the supporting frame, rails are arranged on the supporting frame, the rails comprise a fixed first rail and a movable second rail, a first driving mechanism is arranged on the supporting frame, the first driving mechanism is connected with the driving shaft and the driven shaft, a plurality of rake tooth assemblies are arranged on the first driving mechanism in a sleeving mode, the first driving mechanism can drive the rake tooth assemblies to move in a plane parallel to the first rail, and the second rail is hinged to an oscillating mechanism which can enable the second rail to oscillate horizontally. The loosening device of the separating screen provided by the application has the advantages of simple structure, stable operation, good separating effect and small mechanism vibration and also has a good separating effect on separating and loosening straw with larger humidity.

Owner:蒋和忠

Application of a powder photocatalyst on the surface of a bipolar membrane in CO2 reduction

ActiveCN107099815BMaintain alkaline conditionsSolve difficult to recycleCellsElectrodesSolubilityHydrogenation reaction

A bipolar film surface powder state photocatalyst in the application of CO2 reduction is to use the surface-loaded powder state photocatalytic bipolar film as the diaphragm of the cathode chamber and the anode chamber, and the surface of the cation exchange membrane of the bipolar film is loaded with P-type Semiconductor photocatalyst powder; the surface of the anion exchange membrane of the bipolar membrane is loaded with N-type semiconductor photocatalyst powder, the P-type semiconductor photocatalyst powder is used as a cathode, the N-type semiconductor photocatalyst powder is used as an anode, a xenon lamp is used as a light source, and an external voltage is applied Under the action, the photoelectric catalytic CO2 reduction is carried out, and the water oxidation reaction is carried out in the anode chamber. The water dissociation in the middle interface layer of the bipolar membrane not only provides continuous H+ for CO2 reduction, but also does not cause hydrogen evolution reaction due to high H+ concentration. At the same time, the ionic liquid improves the solubility of CO2 and the transfer rate of protons, improving the efficiency of CO2 reduction. .

Owner:TAIYUAN NORMAL UNIV

Oil-water separation device and machine tool water tank with same

PendingCN111569472ASolve the problem of low separation efficiencyEasy separation efficiencyMagnetic separationLiquid separationMachine toolOil water

The invention provides an oil-water separation device and a machine tool water tank with the same. The oil-water separation device comprises a seat body; a separation structure which comprises a rotating part and a plurality of blades arranged on the rotating part, the blades being arranged at intervals in the circumferential direction of the rotating part and used for stirring an oil-water mixture to be separated; a driving structure which is arranged on the seat body, and is in driving connection with the rotating part to drive the rotating part to drive the blades to rotate; wherein at least part of each blade is made of a lipophilic material. The oil-water separation device effectively solves the problem of low separation efficiency of oil-water separation devices in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

A strong turbulent shear microchannel oil-water separation device

ActiveCN111298481BEfficient demulsificationSolve the problem of low separation efficiencyNon-miscible liquid separationThermodynamicsOil separation

The invention provides a strong turbulent shearing microchannel oil-water separation device, which comprises an oily wastewater storage tank (1), an oil-water delivery pump (2), an oil-water delivery pipe (3), and a pneumatic liquid booster pump ( 4), connecting pipe (5), microchannel (7), liquid collecting pipe (8) and oil-water separation box (9); a pressure gauge (6) is provided on the connecting pipe (5), and on the oil-water separation box ( 9) The oil phase liquid outlet (10) and the water phase liquid outlet (11) are respectively provided on the top, the oil phase switch valve (12) is installed at the front end of the oil phase liquid outlet (10), and the water phase liquid outlet (11) The front end is equipped with a water phase switch valve (13); the device of the present invention has the advantages of small equipment investment, high oil-water separation efficiency, continuous operation of the purification process of oily sewage, etc., and can be widely used in various Efficient purification treatment of oily and dusty wastewater.

Owner:SOUTHEAST UNIV +1

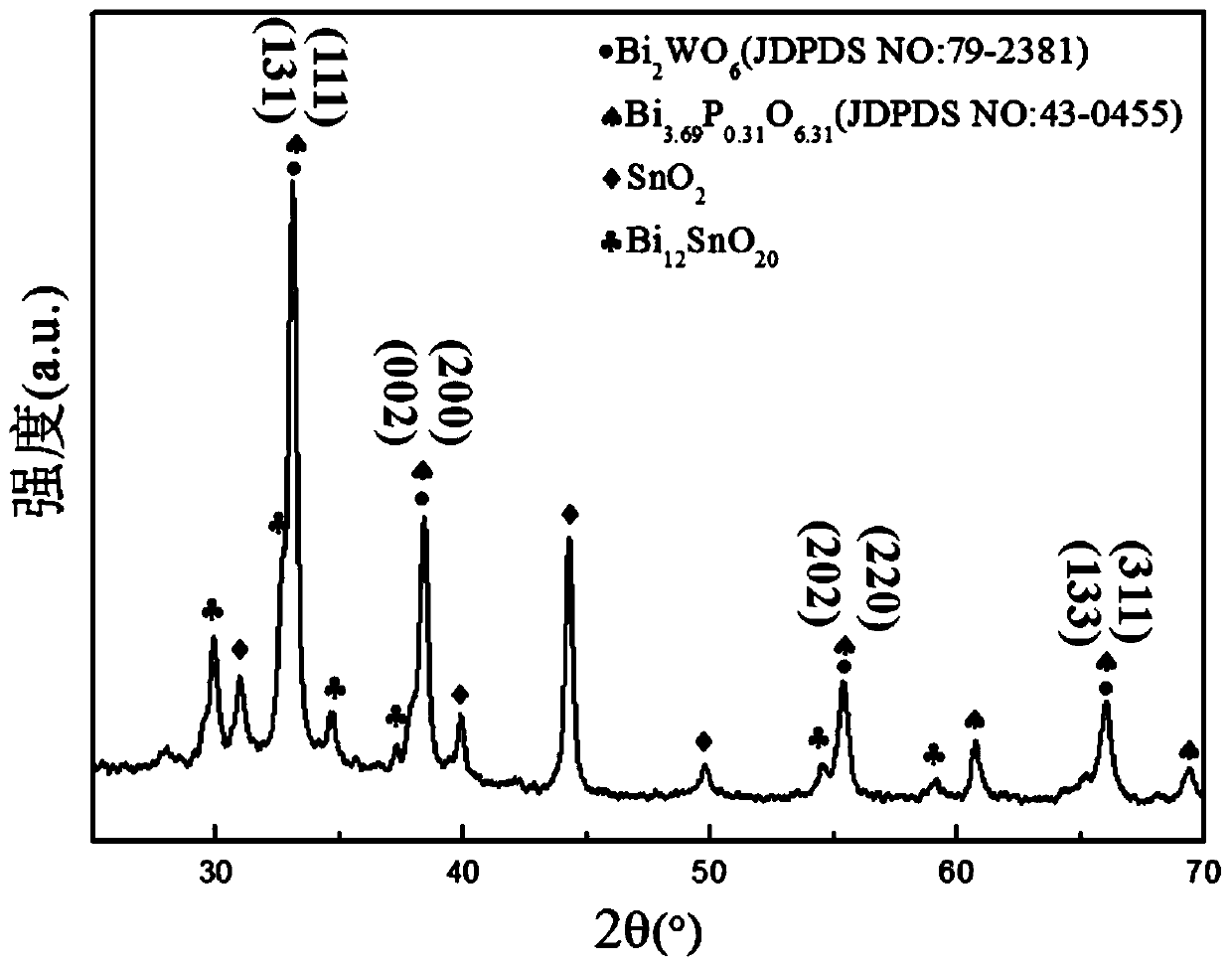

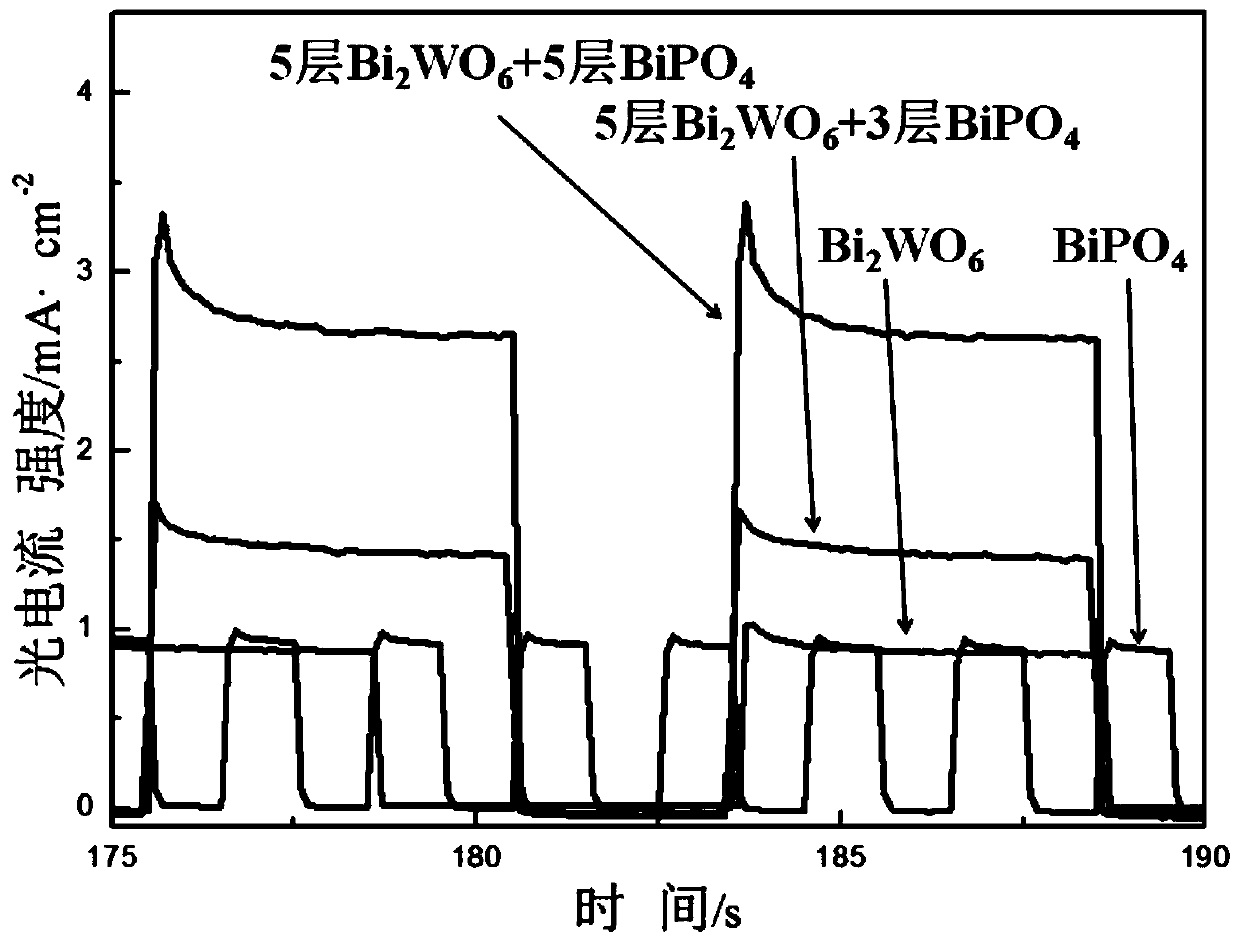

A kind of bismuth tungstate/bismuth phosphate composite thin film and its preparation method and application

ActiveCN106944111BImprove separation efficiencySolve the problem of low separation efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationComposite filmTungstate

The invention discloses a bismuth tungstate / bismuth phosphate composite film and its preparation method and application. Bi is first spin-coated layer by layer on the substrate. 2 WO 6 sol and annealed, when Bi 2 WO 6 After the film reaches a certain thickness, BiPO is spin-coated layer by layer. 4 Sol and anneal at a certain temperature to obtain Bi 2 WO 6 / BiPO 4 Composite film. The present invention adopts the sol-gel process, has simple equipment requirements, and mild experimental conditions. The prepared sol can remain stable for a long time, and the sol concentration is accurately controllable. The prepared bismuth tungstate / bismuth phosphate composite film has good performance under simulated sunlight. 1.423~2.649mA / cm 2 Photoresponse current, Bi 2 WO 6 Films and BiPO 4 The photoresponse current of the film is 2 to 3 times higher. Bi prepared by the present invention 2 WO 6 / BiPO 4 Composite films have broad application prospects in the field of photocatalysis.

Owner:SHAANXI UNIV OF SCI & TECH

Oil-gas separator and crankcase forced ventilation system with same

ActiveCN114483256AChange areaIncrease pressureInternal combustion piston enginesCrankcase ventillationThermodynamicsEngineering

The invention provides an oil-gas separator and a crankcase forced ventilation system with the oil-gas separator, the oil-gas separator comprises a casing and a first gas inlet and a first gas outlet which are arranged on the casing, and the oil-gas separator further comprises a gas inlet pipe arranged in the casing, and a gas outlet pipe arranged in the casing and provided with a first end communicated with the first gas inlet; a plurality of communicating holes are formed in the pipe wall of the air inlet pipe, the communicating holes are sequentially formed in the axial direction of the air inlet pipe, and the air inlet pipe communicates with the first air outlet through the communicating holes; the oil-gas separation piece is arranged in the machine shell, and the oil-gas separation piece is used for separating oil drops in the gas; and the sliding sleeve is arranged in the air inlet pipe, and the sliding sleeve does reciprocating rectilinear motion in the axial direction of the air inlet pipe according to the air inlet amount of the air inlet pipe so as to block different numbers of communicating holes. According to the oil-gas separator, the problem that in the prior art, an oil-gas separator is low in separation efficiency is solved.

Owner:WEICHAI POWER CO LTD

Loosening device of separating screen

InactiveCN106717592AImprove the efficiency of carding and separating riceSolve the problem of low separation efficiencyThreshersDrive shaftPlane parallel

The invention discloses a loosening device of a separating screen. The loosening device comprises a supporting frame, wherein a driving shaft and a driven shaft are arranged on the supporting frame, rails are arranged on the supporting frame, the rails comprise a fixed first rail and a movable second rail, a first driving mechanism is arranged on the supporting frame, the first driving mechanism is connected with the driving shaft and the driven shaft, a plurality of rake tooth assemblies are arranged on the first driving mechanism in a sleeving mode, the first driving mechanism can drive the rake tooth assemblies to move in a plane parallel to the first rail, and the second rail is hinged to an oscillating mechanism which can enable the second rail to oscillate horizontally. The loosening device of the separating screen provided by the application has the advantages of simple structure, stable operation, good separating effect and small mechanism vibration and also has a good separating effect on separating and loosening straw with larger humidity.

Owner:蒋和忠

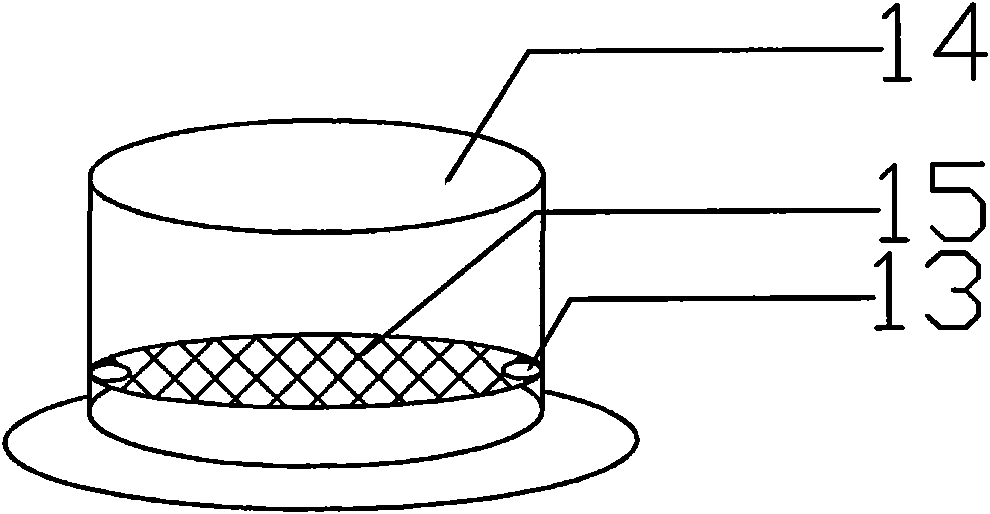

Combined type soil animal separator

InactiveCN101695675BEfficient separationControl roasting intensityLaboratory glasswaresCovering systemEngineering

The invention relates to the technical field of agriculture, and in particular provides a combined type soil animal separator, which can separate various soil animals effectively. The structure of the combined type soil animal separator comprises a separating rack of which the top is provided with a top cover system; the separating rack is provided with a hopper position perforated plate; a hopper is arranged on the hopper position perforated plate; a material bin of the separator is arranged above the hopper; and a soil animal collector is arranged below the hopper. Compared with the prior art, the combined type soil animal separator has the characteristics of rational design, simple structure, high separation efficiency, strong comparability, adjustment and selectivity, capability of controlling temperature and time automatically, capability of being applied to a plurality of sample sizes and the like.

Owner:广东省农业科学院土壤肥料研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com