Application of a powder photocatalyst on the surface of a bipolar membrane in CO2 reduction

A photocatalyst, bipolar membrane technology, applied in electrodes, cells, electrolytic components, etc., can solve the problems of easy agglomeration of powder, difficult to recycle, low photo-generated electron-hole separation efficiency, etc., to improve solubility, solve easy agglomeration, The effect of increasing the transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

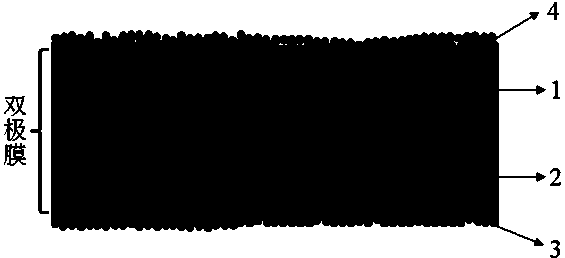

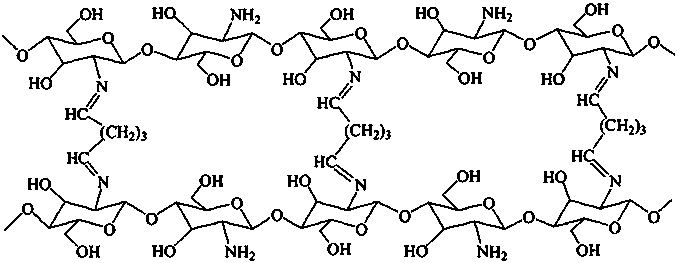

[0033] The bipolar membrane with powder state photocatalysis attached to the surface is used as the diaphragm of the cathode chamber and the anode chamber (wherein the cation exchange membrane constituting the bipolar membrane is attached with Ag 2 O semiconductor photocatalyst powder, TiO is attached to the surface of the anion exchange membrane constituting the bipolar membrane 2 semiconductor photocatalyst powder), the Ag 2 O semiconductor photocatalyst powder material as a cathode, the TiO 2 The semiconductor photocatalyst powder material is used as the anode, the catholyte material is 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, the anolyte is 0.5 M KOH, a xenon lamp is used as the simulated sunlight light source, and the applied voltage is Under the action of 0.5 V, the cathode chamber performs photocatalytic CO 2 Reduction, the anode chamber carries out the water oxidation reaction.

[0034] After the experiment, the catholyte was collected, the CO con...

Embodiment approach 2

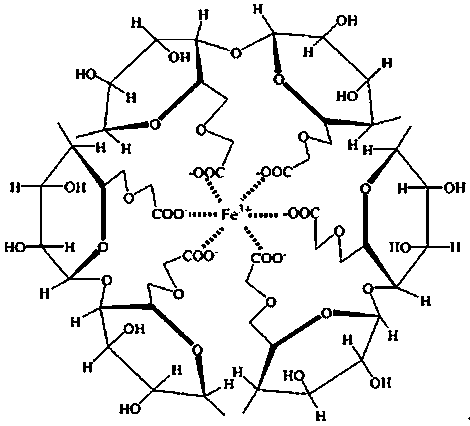

[0036] The bipolar membrane with powder state photocatalysis attached to the surface is used as the diaphragm of the cathode chamber and the anode chamber (wherein the cation exchange membrane constituting the bipolar membrane is attached with Ag 2 O semiconductor photocatalyst powder, with Fe attached to the surface of the anion exchange membrane constituting the bipolar membrane 2 o 3 semiconductor photocatalyst powder), the Ag 2 O semiconductor photocatalyst powder material as a cathode, the Fe 2 o 3 The semiconductor photocatalyst powder material is used as the anode, the catholyte material is 1-butyl-3-methylimidazolium chloride ionic liquid, the anolyte is 1.0 M KOH, the xenon lamp is used as the simulated sunlight light source, and the applied voltage is 0.8 V. Next, the cathode chamber performs photocatalytic CO 2 Reduction, the anode chamber carries out the water oxidation reaction.

[0037] After the experiment, the catholyte was collected, the CO content genera...

Embodiment approach 3

[0039] The bipolar membrane with powder state photocatalysis attached to the surface is used as the diaphragm of the cathode chamber and the anode chamber (wherein, the surface of the cation exchange membrane constituting the bipolar membrane is attached with CoO semiconductor photocatalyst powder, and the surface of the anion exchange membrane constituting the bipolar membrane is adhered ZnO semiconductor photocatalyst powder), CoO semiconductor photocatalyst powder material is used as cathode, ZnO semiconductor photocatalyst powder material is used as anode, catholyte material is N-ethylpyridine hexafluorophosphate ionic liquid, anolyte is 0.5 M NaOH, using a xenon lamp as a simulated sunlight light source, under the action of an applied voltage of 1.0 V, the cathode chamber was used for photocatalytic CO 2 Reduction, the anode chamber carries out the water oxidation reaction.

[0040] After the experiment, the catholyte was collected, the CO content generated was calibrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com