Preparation of photoelectric catalytic membrane for preparing hydrogen by decomposing water

A technology for photoelectric catalysis and water splitting, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, diaphragms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

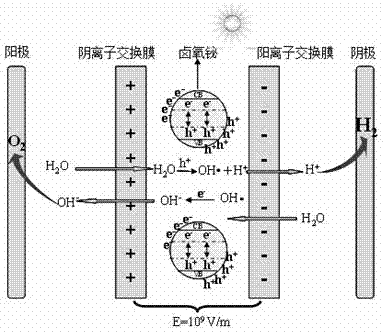

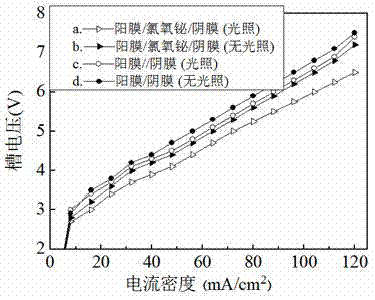

[0031] The preparation method of a photoelectric catalytic film for decomposing water to produce hydrogen is as follows.

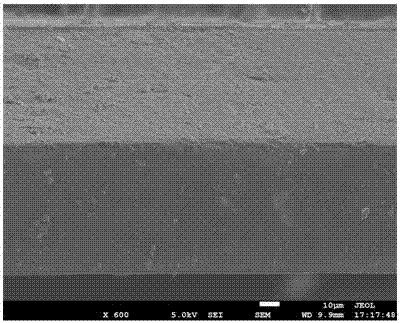

[0032] (1) Weigh 2.0 g of sodium cellulose acetate and 3.0 g of polyvinylpyrrolidone and mix them in a beaker, heat and stir to dissolve with distilled water, cast on a flat glass plate, dry in an oven at 20°C to form a film, and then use heavy metals Ion Ti 4+ Cross-link for 5 minutes, and then use the -PO 4 The solution is soaked for 5 minutes and dried at room temperature; a positive film with a thickness of 50 μm is obtained.

[0033] (2) Weigh 0.1 g of bismuth oxychloride catalyst uniformly dispersed in absolute ethanol under ultrasonic vibration, pour it on the surface of the positive film obtained in step (1) above, and air dry at 20°C to obtain a bismuth oxychloride film with a thickness of 0.05μm .

[0034] (3) Weigh 2.0 g of chitosan and 3.0 g of polyvinylpyrrolidone and mix them in a beaker, heat and stir to dissolve with 0.25% acetic acid aqueous...

Embodiment approach 2

[0038] The preparation method of a photoelectric catalytic film for decomposing water to produce hydrogen is as follows.

[0039] (1) Weigh 3.0 g sodium carboxymethyl cellulose and 4.0 g polyvinylpyrrolidone and mix them in a beaker, heat and stir to dissolve with distilled water, cast on a flat glass plate, dry in an oven at 25°C to form a film, and then Using heavy metal ion Ti 4+ Cross-link for 10 minutes, then use -PO 4 Soak the solution for 10 minutes and dry at room temperature to obtain a positive film with a thickness of 50 μm.

[0040] (2) Weigh 0.3 g of bismuth oxychloride catalyst uniformly dispersed in absolute ethanol under ultrasonic vibration, pour it on the surface of the positive film prepared in step (1) above, and air dry at 25°C to obtain a bismuth oxychloride film with a thickness of 0.05μm .

[0041] (3) Weigh 3.0 g of chitosan and 4.0 g of polyvinylpyrrolidone and mix them in a beaker, heat and stir to dissolve with 0.5% acetic acid aqueous solution, add g...

Embodiment approach 3

[0045] The preparation method of a photoelectric catalytic film for decomposing water to produce hydrogen is as follows.

[0046] (1) Weigh 5.0 g of sodium cellulose acetate and 6.0 g of polyvinylpyrrolidone, mix them in a beaker, heat and stir to dissolve with distilled water, cast on a flat glass plate, dry in an oven at 30°C to form a film, and then use heavy metals Ion Ti 4+ Cross-link for 15 minutes, then use -HSO 3 Soak the solution for 15 minutes and dry at room temperature to obtain a positive film with a thickness of 50 μm.

[0047] (2) Weigh 0.5 g of bismuth oxybromide catalyst uniformly dispersed in absolute ethanol under ultrasonic vibration, pour it on the surface of the positive film prepared in step (1) above, and air dry at 30°C to obtain a bismuth oxybromide film with a thickness of 0.05μm .

[0048] (3) Weigh 5.0 g of chitosan and 6.0 g of polyvinylpyrrolidone, mix them in a beaker, heat and stir to dissolve with 0.75% acetic acid aqueous solution, add succinal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com