Method for efficiently separating zhongshengmycin from fermentation liquor

A technology for biotin and fermentation broth, applied in the field of high-efficiency separation of biotin, can solve the problems of many solid hazardous wastes, unfavorable environmental control, complicated preparation process, etc., to reduce production difficulty and quality control cost, and improve sustainable The effect of high development and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

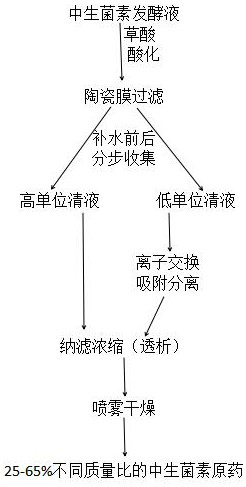

Image

Examples

Embodiment 1

[0036] 1) The fermented liquid is acidified with oxalic acid to pH 2.5-3.0, the ceramic clear liquid before and after adding water is filtered by the ceramic membrane, and collected into high-unit clear liquid tanks and low-unit clear liquid tanks respectively. The potency of bacterial residue is 500-800u / ml, The potency of materials is controlled in the range of 1500-3500u / ml and 5500-8500u / ml, the volume of ceramic clear liquid is 2.3-2.5BV, the yield of materials is controlled in the range of 35-40%, 55-60%, and the total yield is 94.5% above.

[0037] 2) The ion exchange resin model is LX-731-X1 modified resin, the production expansion coefficient is 1.5-2.0, and the packing volume is about 50%. Low unit tank materials enter the separation resin for adsorption, the adsorption feed volume rate is 0.2-1.0BV / h (effective rate 2-4kg / t.h -1 ), the pH of the adsorption end is 6.5-7.0, the total adsorption volume is 70-80BV, and the adsorption capacity is controlled at 130-140kg...

Embodiment 2

[0043] 1) to 3) steps are the same;

[0044] 4) Concentrated mother liquor of eluent and concentrated mother liquor of high unit supernatant are mixed according to (1:1-3:1), spray-dried, and the content of the original drug is 35-45%;

[0045] 5) The concentration of nanofiltration is more than 96%, the yield of spray drying is more than 86%, and the total yield of production is between 78-85%.

Embodiment 3

[0047] 1) to 3) steps are the same;

[0048] 4) After the high unit tank material and eluent are mixed, nanofiltration is concentrated to 40,000-55,000 units, spray-dried, and the content of the original drug is 45-55%;

[0049] 5) The concentration of nanofiltration is more than 96%, the yield of spray drying is more than 86%, and the total yield of production is between 78-85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com