Preparation method of high-flux polyimide composite ultrafiltration membrane

A technology of polyimide and ultrafiltration membrane, which is applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problem of low flux, and achieve the effect of simple operation, low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

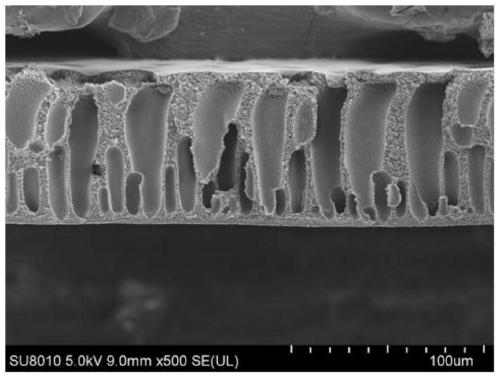

Image

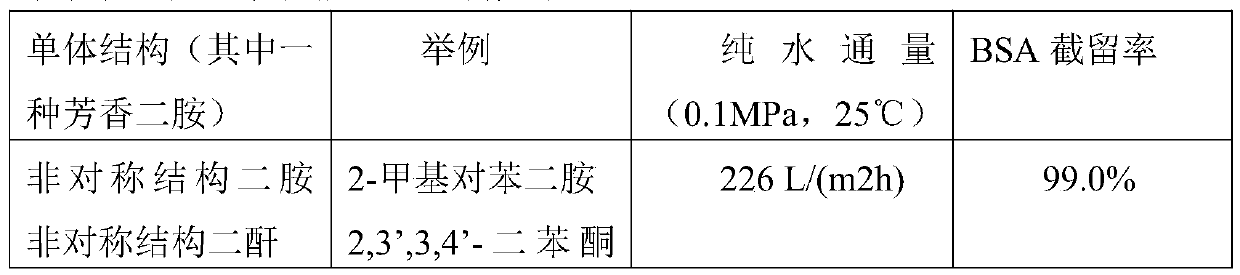

Examples

Embodiment 1

[0030] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application. Embodiment 1: a kind of preparation method of high flux polyimide composite ultrafiltration membrane, it may further comprise the steps:

[0031] Step (1): Dissolve dry 4,4'-diaminodiphenylmethane and p-phenylenediamine at a molar ratio of 1:1 in N-methylpyrrolidone, stir thoroughly for 2 hours, and then dry the Tetracarboxylic dianhydride and 3,3',4,4'-benzophenone tetracarboxylic dianhydride were added to the solution, and the polyamic acid solution was obtained after stirring and reacting at 70°C...

Embodiment 2

[0038] Embodiment 2: a kind of preparation method of high flux polyimide composite ultrafiltration membrane, it may further comprise the steps:

[0039] Step (1): Dissolve dry 3,3'-dimethyl-4,4'-diphenylmethanediamine and p-phenylenediamine at a molar ratio of 1:1 in N-methylpyrrolidone and stir well 1 hour, then add dry 3,3',4,4'-biphenyltetraic dianhydride and 4,4'-hexafluoroisopropylidene-phthalic anhydride to the solution, and stir at 40°C for reaction After 4 hours, a polyamic acid solution was obtained; wherein 3,3'-dimethyl-4,4'-diphenylmethanediamine or p-phenylenediamine and aromatic dianhydride (3,3',4,4'-linked The mol ratio of pyromellitic dianhydride and 4,4'-hexafluoroisopropylidene-phthalic anhydride) is 1:1.02;

[0040]Step (2): Add pyridine and acetic anhydride to the polyamic acid solution obtained in step (1), stir and react for 1 hour, then cool to room temperature, slowly add methanol dropwise under stirring until the color of the solution changes complet...

Embodiment 3

[0045] Embodiment 3: a kind of preparation method of high flux polyimide composite ultrafiltration membrane, it comprises the following steps:

[0046] Step (1): Dissolve dry 4,4'-diaminodiphenylmethane and p-phenylenediamine at a molar ratio of 1:1 in N,N-dimethylformamide, stir thoroughly for 1 hour, and then Dry pyromellitic dianhydride and 4,4'-hexafluoroisopropylidene-phthalic anhydride are added to the solution, and the polyamic acid solution is obtained after stirring and reacting at 90°C for 10 hours; where 4,4'- The molar ratio of diaminodiphenylmethane or p-phenylenediamine to aromatic dianhydride (pyromellitic dianhydride and 4,4'-hexafluoroisopropylidene-phthalic anhydride) is 1:1.02;

[0047] Step (2): Add triethylamine and propionic anhydride to the polyamic acid solution obtained in step (1), stir and react for 2 hours, then cool to room temperature, slowly add methanol with a volume concentration of 50% under stirring until the color of the solution Completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

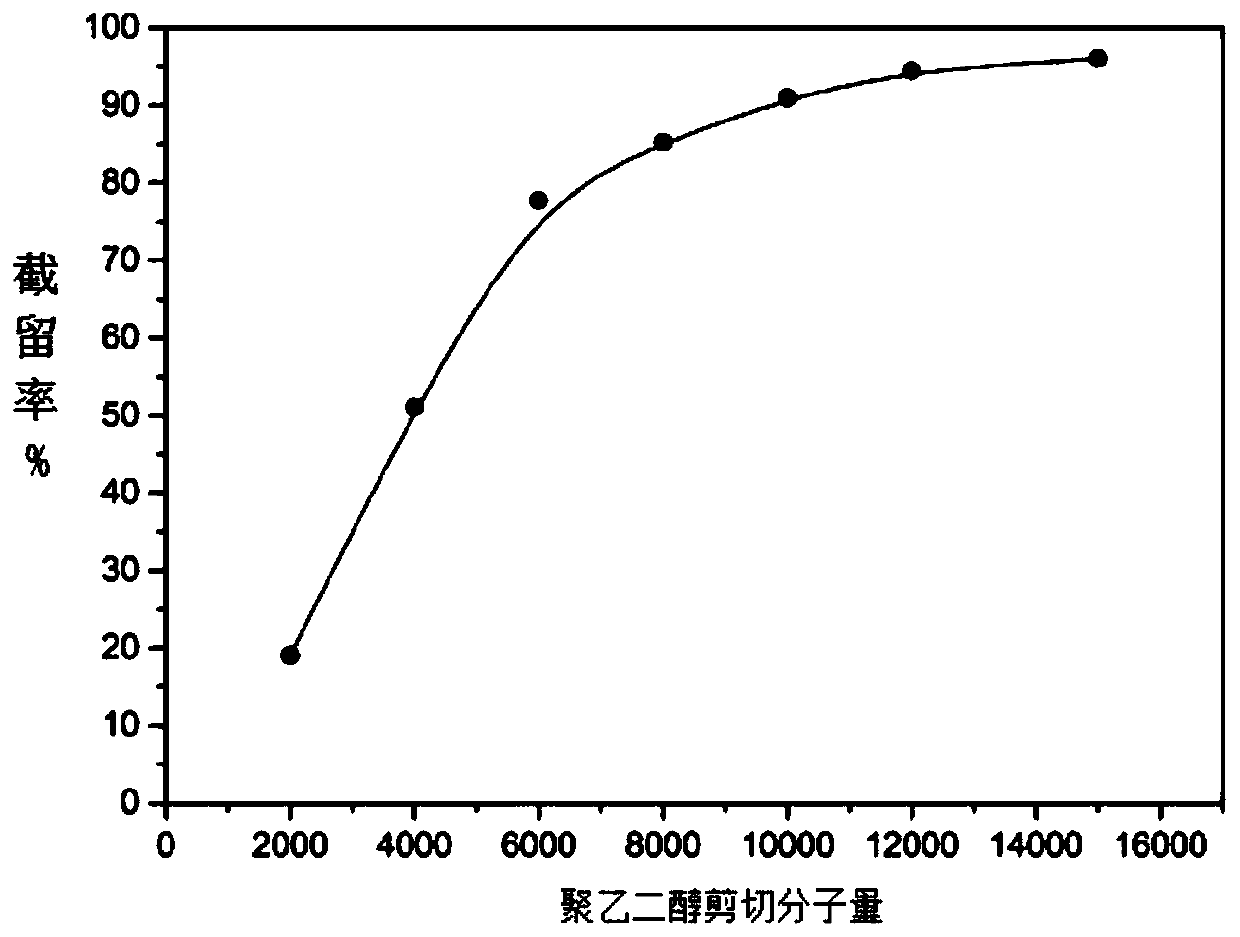

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com