Strong turbulence shearing micro-channel oil-water separation device

An oil-water separation device and microchannel technology, applied in liquid separation, separation method, immiscible liquid separation, etc., can solve the problems of low separation efficiency of small droplets, complex equipment structure, high energy consumption, etc., and achieve high-efficiency demulsification, Reduced transmission resistance, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

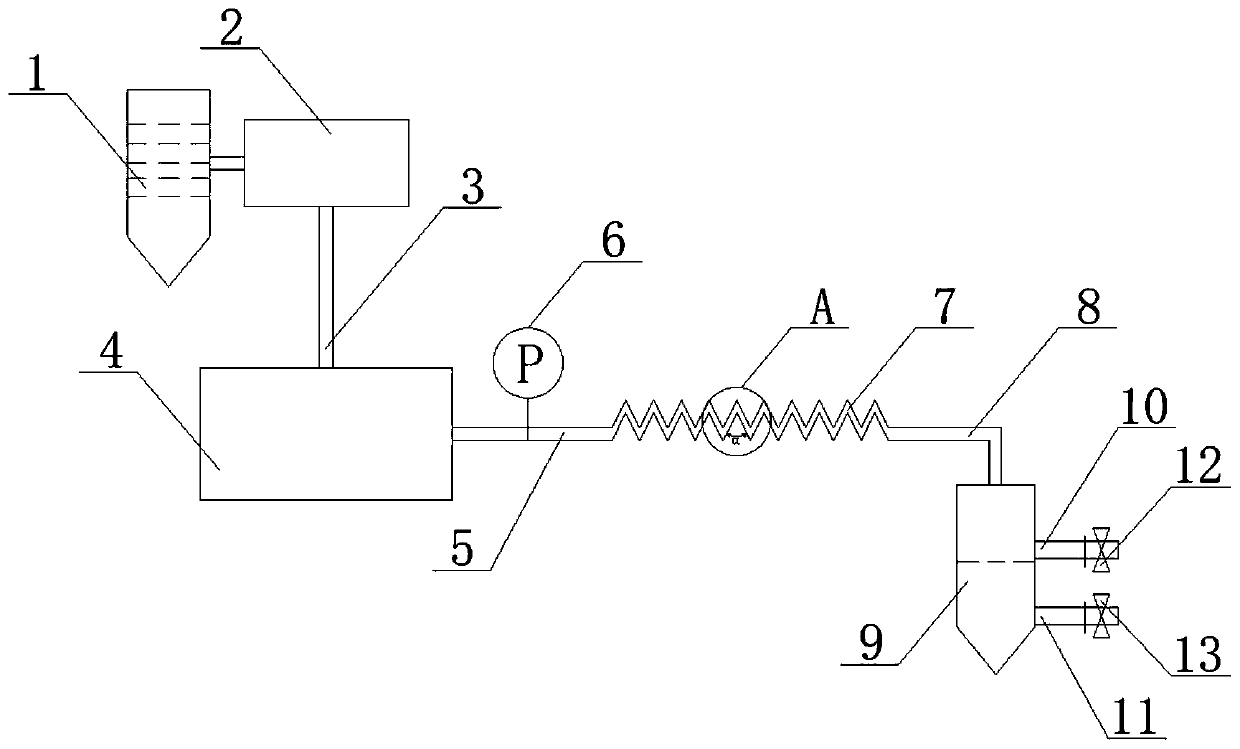

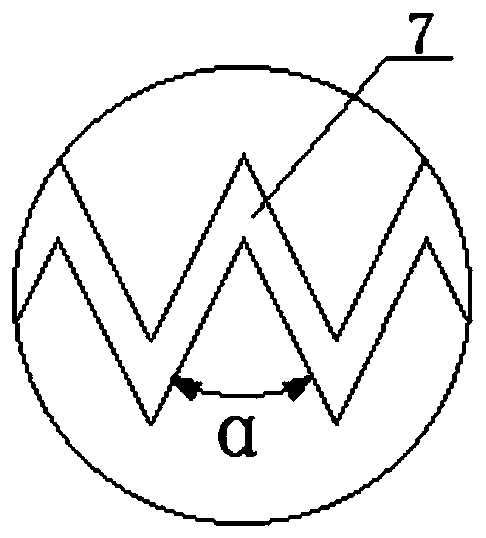

[0035] For a strong turbulent shear microchannel oil-water separation device, see figure 1 , the oily wastewater storage tank 1 is used to place oil and water, start the oily water delivery pump 2 to extract the oily water from the oily wastewater storage tank 1, and enter the pneumatic liquid booster pump 4 through the oily water delivery pipe 3, and the pneumatic liquid booster pump 4 is in the external low-pressure air Driven by the pressure, the oil-water mixture is effectively pressurized and then enters the microchannel 7 through the connecting pipe 5. At the same time, the pressure of the high-pressure liquid is detected by the pressure gauge 6. The high-pressure liquid generates a strong turbulent shear flow field in the microchannel 7, realizing High-efficiency demulsification of the oil-water two-phase, the liquid after demulsification enters the oil-water separation tank 9 through the liquid collection pipe 8 for collection, and what is collected is the liquid in whi...

Embodiment 2

[0038] For a strong turbulent shear microchannel oil-water separation device, see figure 1 , the oily wastewater storage tank 1 is used to store oil and water, start the oily water delivery pump 2 to extract the oily water from the oily wastewater storage tank 1, and enter the pneumatic liquid booster pump 4 through the oily water delivery pipe 3, and the pneumatic liquid booster pump 4 is externally low pressure Driven by the air, the oil-water mixture is effectively pressurized and then enters the microchannel 7 through the connecting pipe 5. At the same time, the pressure of the high-pressure liquid is detected by the pressure gauge 6. The high-pressure liquid generates a strong turbulent shear flow field in the microchannel 7. Realize the high-efficiency demulsification of the two phases of oil and water. The liquid after demulsification enters the oil-water separation box 9 through the liquid collection pipe 8 for collection. The liquid in the upper layer is oil and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com