Gas-liquid baffle separation device

A liquid separation and gas flow technology, which is applied in the field of devices for baffled separation of gas-liquid two-phase flow, can solve the problems of affecting separation efficiency, separation method and single application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

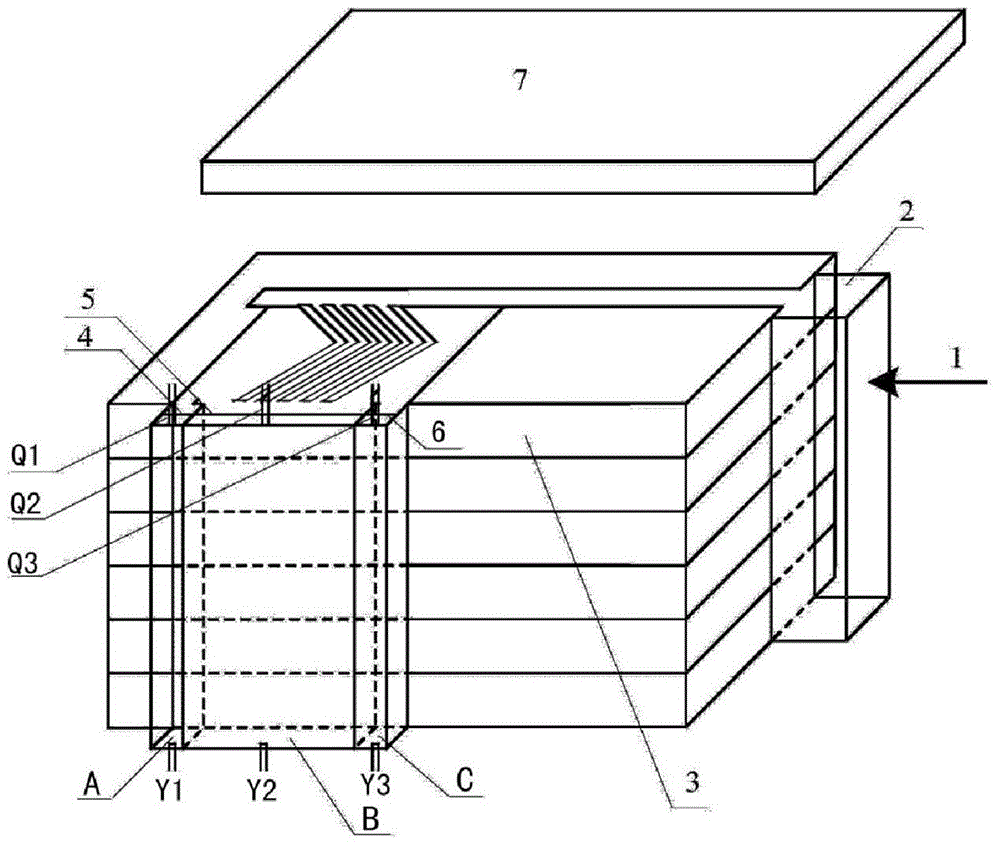

[0011] figure 1 is a schematic diagram of the baffled gas-liquid separation device of the present invention, figure 2 is a structural schematic diagram of the separator of the present invention, such as Figure 1 to Figure 2 shown. The baffle gas-liquid separation device of the present invention comprises a gas-liquid input port 1, an inlet distribution chamber 2, a pre-separator, a protection plate 7, and a separation chamber;

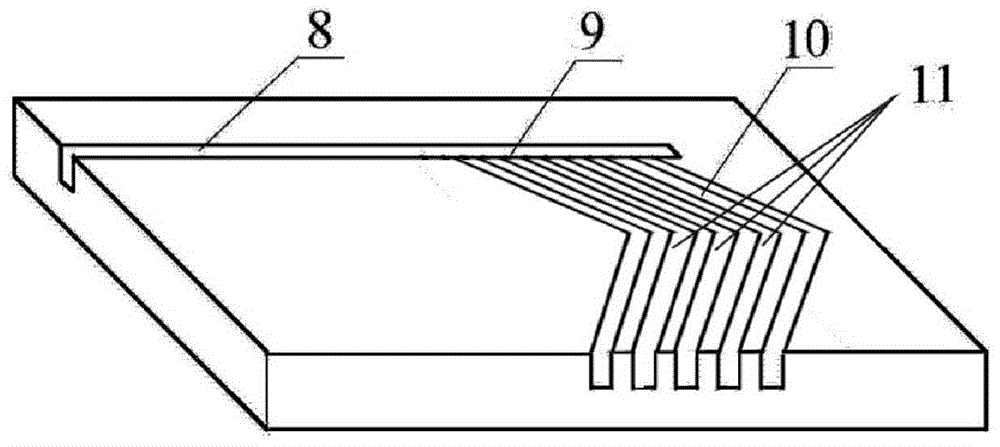

[0012] The above separation chambers include separation chamber A, separation chamber B, and separation chamber C. The upper end of each separation chamber is respectively provided with gas phase separation outlets Q1, Q2, Q3, and the lower end is respectively provided with liquid phase separation outlets Y1, Y2, Y3; wherein, the pre-separator is formed by stacking multiple partitions 3, and each partition 3 is provided with a main channel 8 of the input port and a plurality of sub-channels communicated with the above-mentioned main channel 8; each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com