Printing ink preparation device

A technology for preparing device and printing ink, which is applied to mixers with rotary stirring devices, transportation, packaging, dissolving and other directions, and can solve the problems that the ink is not easy to stir and mix evenly, dangerous, and climbs on the stirring tank manually.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

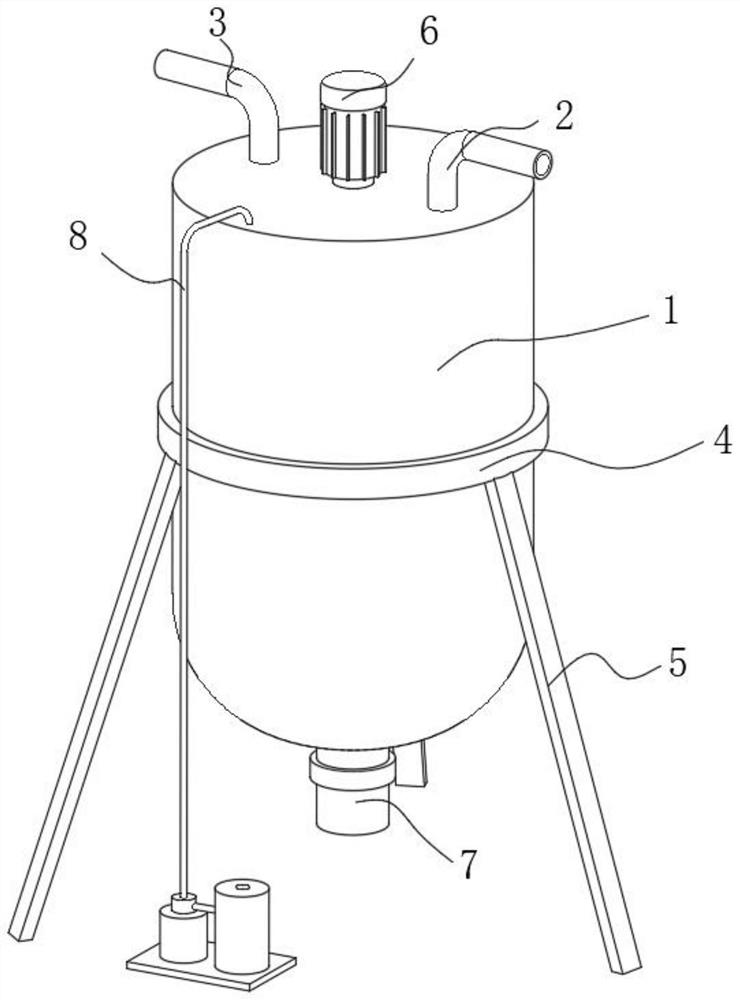

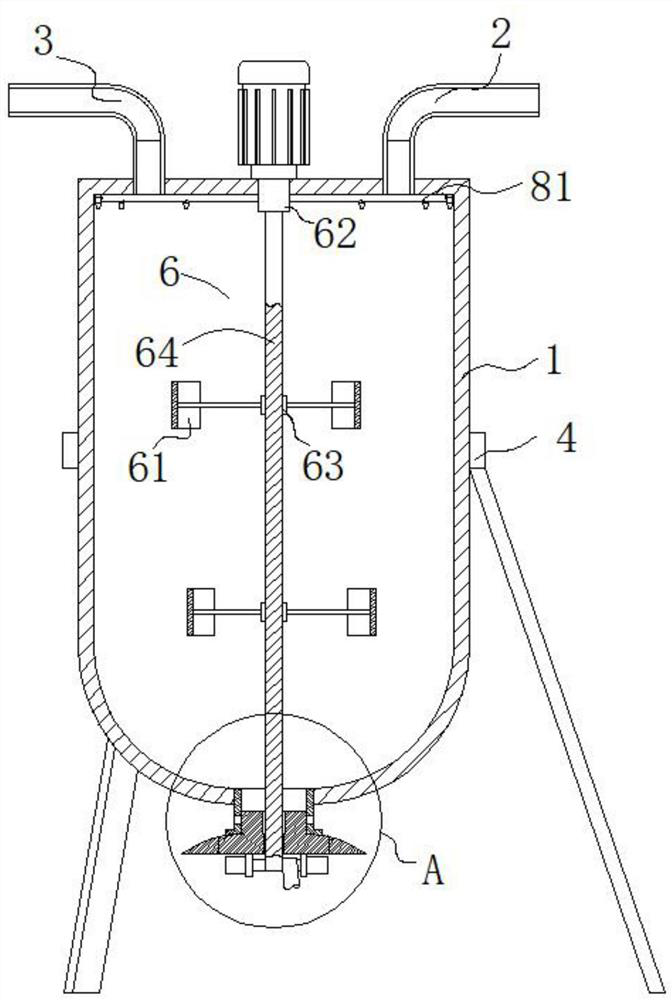

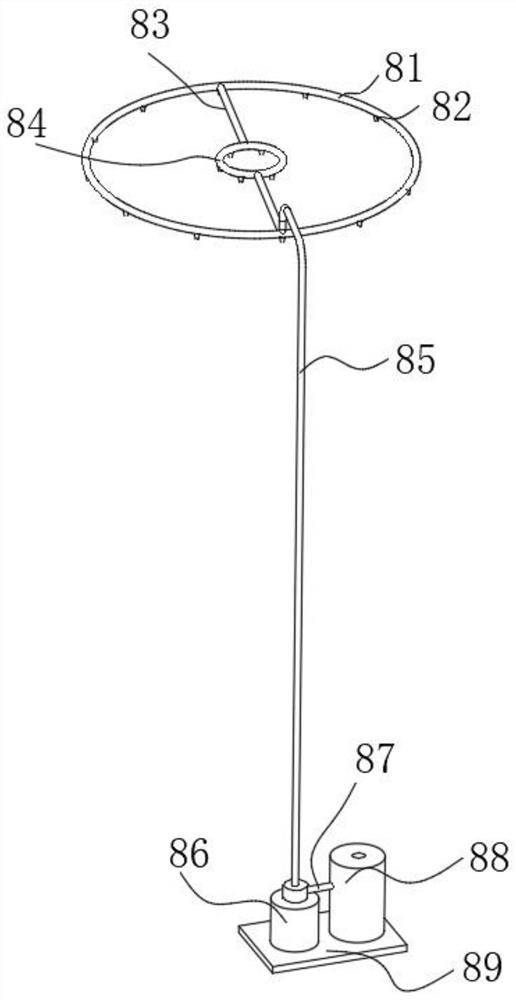

[0022] Such as Figure 1-5 As shown, a printing ink preparation device includes a stirring tank 1, the top of the stirring tank 1 is provided with a first feeding pipe 2 and a second feeding pipe 3, and the middle part of the outer wall of the stirring tank 1 is fixed with a fixing hoop 4; The upper hinge of the fixed hoop 4 is hinged with a telescopic foot 5, and the lower end of the telescopic foot 5 is hinged on the mounting base for supporting and deflecting the placement angle of the stirring tank 1; Stirring mechanism 6, the bottom of the stirring tank 1 is provided with a feeding mechanism 7; the feeding mechanism 7 is used to cooperate with the stirring mechanism 6 to change the trajectory of the ink being stirred in real time according to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap