Preparation method of instrument pressure guide pipe

A preparation method and technology of pressure guide tubes, which are applied in the field of instrument pressure guide tubes, can solve the problems of time delay, time-consuming preparation and installation process, etc., and achieve the effects of convenient size measurement, fast preparation, and easy piping direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

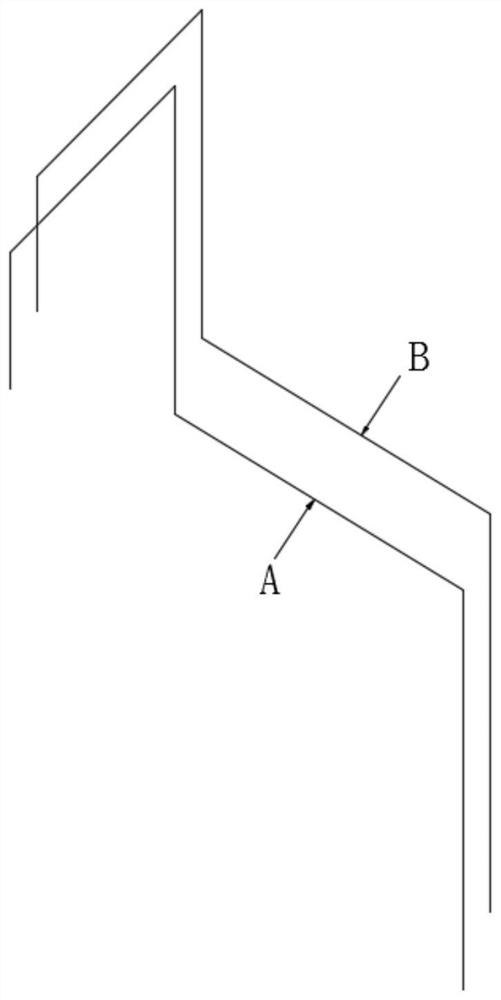

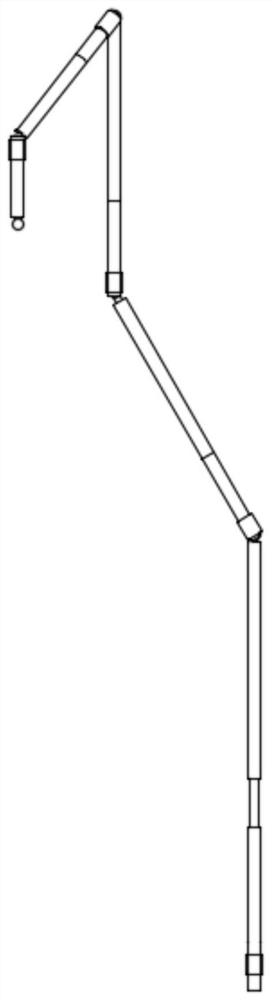

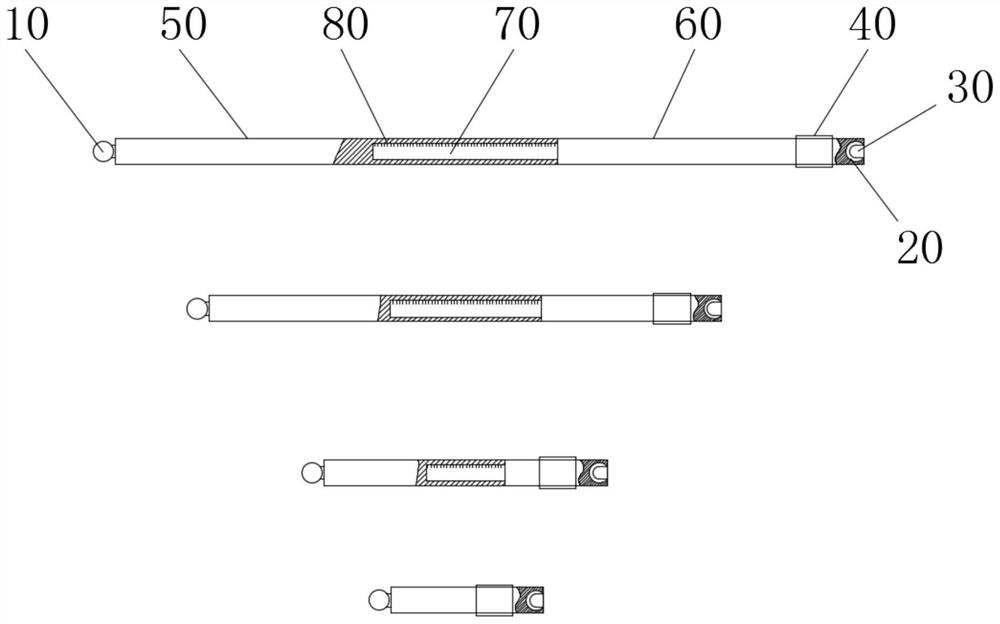

[0023] Such as figure 1 As shown, the preparation method of the instrument pressure guiding tube of the present embodiment includes the following steps:

[0024] Step (1): When preparing the on-site instrument pressure guiding pipe, determine the elevation and direction of the instrument piping pressure guiding pipe according to the actual conditions of the on-site process pipeline;

[0025] Step (2): Use the preparation tool to follow the direction of the process pipeline, and the preparation tool simulates the length and direction of the process pipeline. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com