A system and method for in-situ continuous neutralization of acid tailings leachate

A leachate and acidic technology, applied in the field of soil pollution treatment, can solve the problems of uncontrolled soil acidification in the lower layer, heavy metal pollution in groundwater acidification, and difficulty in determining the amount of alkaline mixture, etc., to achieve stable treatment effect and cost The effect of low and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

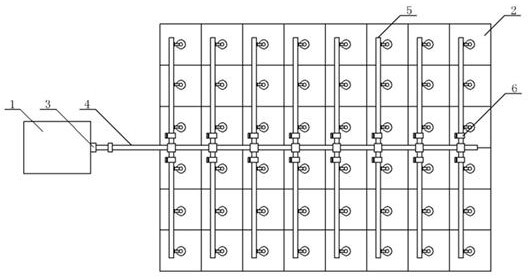

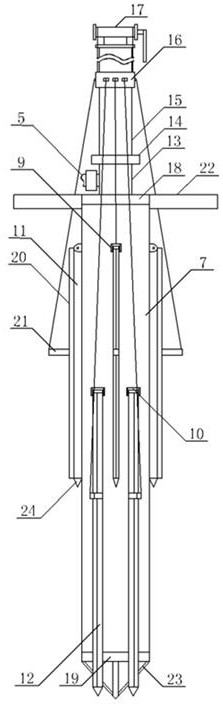

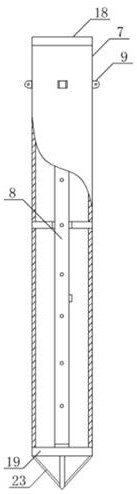

[0039] Such as Figures 1 to 4 As shown, the system for in-situ continuous neutralization of acid tailings leachate includes a liquid storage tank 1, a pipeline system and an alkaline treatment liquid irrigation device; the pipeline system includes a main valve 3, a main pipeline 4, a branch pipeline 5 and Branch valve 6, the alkaline treatment liquid watering device includes casing 7, watering pipe 8, first hinged seat 9, second hinged seat 10, first movable frame 11, second movable frame 12, liquid supply chamber 13, Pedestal 14, sliding column 15, sliding sleeve 16, rope winding device 17, upper end cover 18, lower end cover 19, cone platform 20, rope connection position 21, foot pedal 22, cone-shaped soil breaking frame 23 and cone-shaped soil breaking head 24 ;

[0040] Described reservoir 1 is connected main pipeline 4 by pump, and main pipeline 4 is provided with some branch pipelines 5, and each branch pipeline 5 pipelines connects each alkaline treatment liquid water...

Embodiment 2

[0048] Such as Figures 1 to 4 As shown, the system for in-situ continuous neutralization of acid tailings leachate includes a liquid storage tank 1, a pipeline system and an alkaline treatment liquid irrigation device; the pipeline system includes a main valve 3, a main pipeline 4, a branch pipeline 5 and Branch valve 6, the alkaline treatment liquid watering device includes casing 7, watering pipe 8, first hinged seat 9, second hinged seat 10, first movable frame 11, second movable frame 12, liquid supply chamber 13, Pedestal 14, sliding column 15, sliding sleeve 16, rope winding device 17, upper end cover 18, lower end cover 19, cone platform 20, rope connection position 21, foot pedal 22, cone-shaped soil breaking frame 23 and cone-shaped soil breaking head 24 ;

[0049] Described reservoir 1 is connected main pipeline 4 by pump, and main pipeline 4 is provided with some branch pipelines 5, and each branch pipeline 5 pipelines connects each alkaline treatment liquid water...

Embodiment 3

[0057] Such as Figures 1 to 4 As shown, the system for in-situ continuous neutralization of acid tailings leachate includes a liquid storage tank 1, a pipeline system and an alkaline treatment liquid irrigation device; the pipeline system includes a main valve 3, a main pipeline 4, a branch pipeline 5 and Branch valve 6, the alkaline treatment liquid watering device includes casing 7, watering pipe 8, first hinged seat 9, second hinged seat 10, first movable frame 11, second movable frame 12, liquid supply chamber 13, Pedestal 14, sliding column 15, sliding sleeve 16, rope winding device 17, upper end cover 18, lower end cover 19, cone platform 20, rope connection position 21, foot pedal 22, cone-shaped soil breaking frame 23 and cone-shaped soil breaking head 24 ;

[0058] Described reservoir 1 is connected main pipeline 4 by pump, and main pipeline 4 is provided with some branch pipelines 5, and each branch pipeline 5 pipelines connects each alkaline treatment liquid water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com