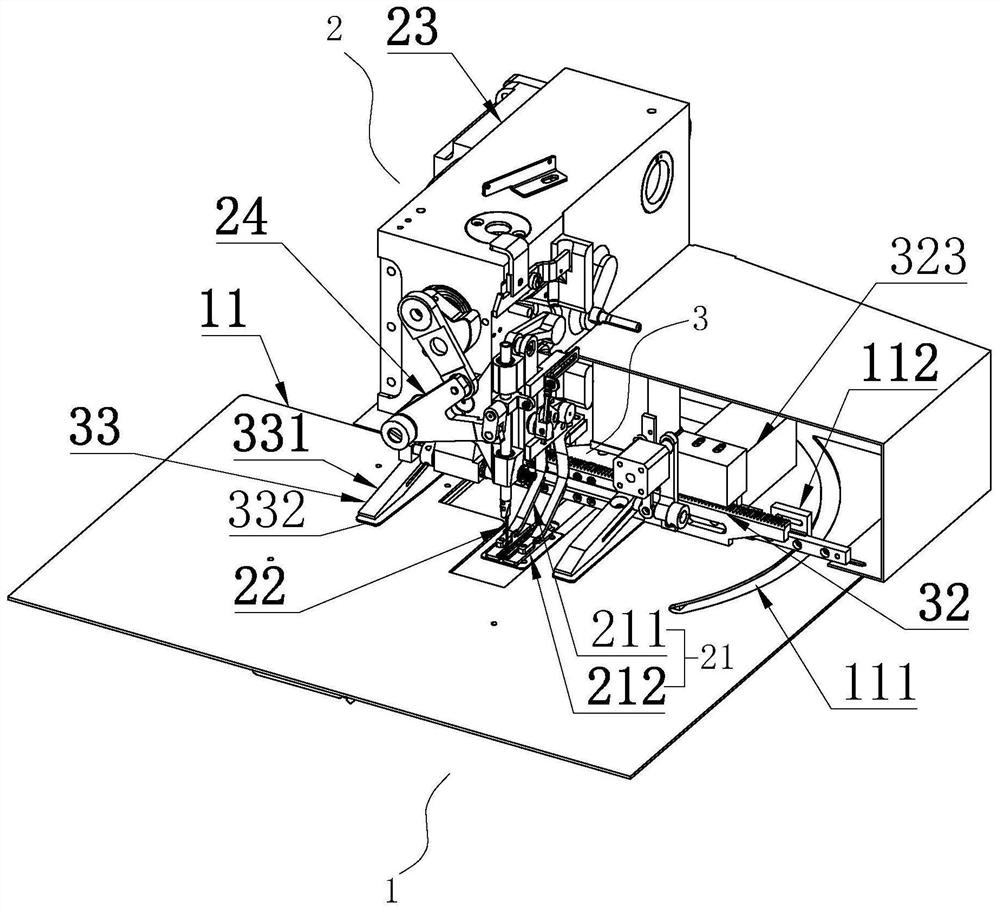

Automatic continuous sewing device of mock button hole machine

A technology of artificial eye machine and mobile device, which is applied in the direction of cloth feeding mechanism, cloth pressing mechanism, sewing equipment, etc., and can solve problems such as single function, low processing efficiency, and too long swing mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

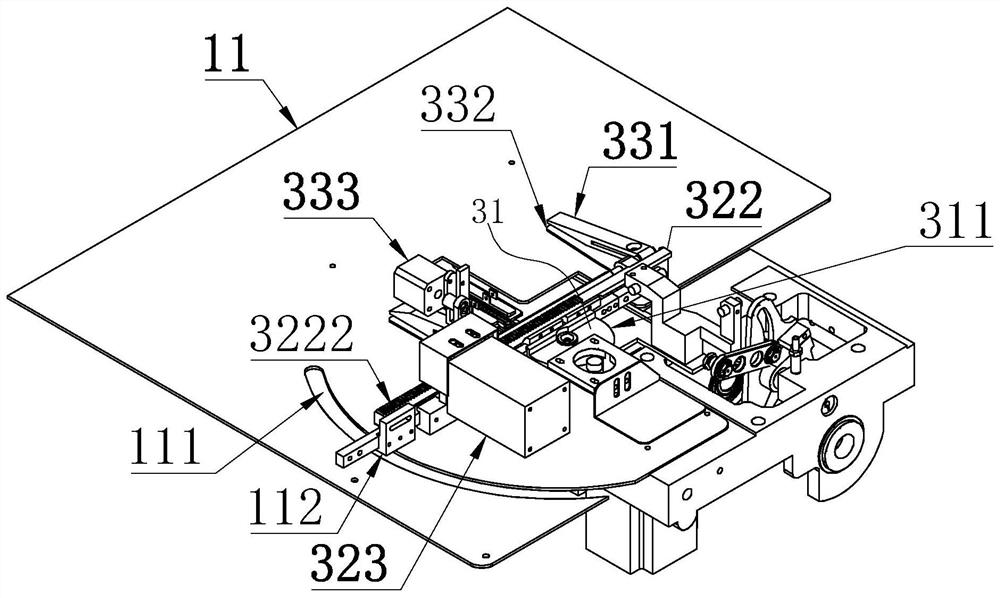

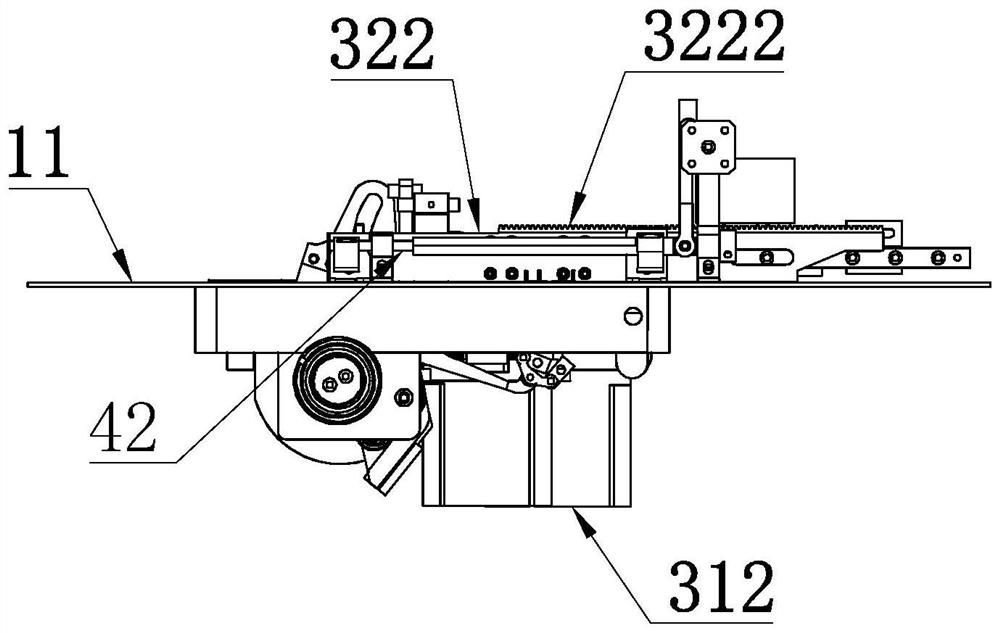

[0036] As an improved specific implementation, several pulleys 32211 are provided on the lower side of the sliding bar 3221 .

[0037] Through the above technical solution, the pulley 32211 is in conflict with the support groove 3211, which reduces friction, reduces power consumption of the reciprocating motor 323, saves energy and protects the environment, reduces wear and prolongs service life.

[0038] As an improved specific embodiment, the lower clamping plate 331 is provided with a lower protrusion 3311 , and the upper clamping plate 332 is provided with several upper protrusions 3321 , and the lower protrusions 3311 and the upper protrusions 3321 are dislocated.

[0039] Through the above technical solution, when the lower clamping plate 331 and the upper clamping plate 332 clamp the cloth, the upper protrusion 3321 and the lower protrusion 3311 are respectively located on the upper and lower sides of the cloth, and the upper protrusion 3321 and the lower protrusion 3311...

Embodiment approach

[0046] As an improved specific embodiment, the presser foot device 21 includes two pressing rods 211, the ends of the pressing rods 211 are provided with pressing plates 212, and the pressing plates 212 are located on both sides of the sewing needle 22 respectively. An accommodating area 213 is provided between the rods 211 , and the driving rod 43 , the push rod 44 and the clamping cylinder 333 are located in the accommodating area 213 .

[0047] Through the above-mentioned technical scheme, the two pressing rods 211 respectively drive the two pressing plates 212 to press the two sides of the sewing needle 22, so as to avoid skipped stitches during sewing and have high stability. At the same time, the driving rod 43, the push rod 44 and the clamping cylinder 333 are located In the accommodation area 213, it is located between the two clamping parts 334. When the program controls the clamping part 334 to clamp the cloth, the operation of the clamping cylinder 333 drives the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com