Multifunctional single/compound doping particle lignin and basalt fiber feeding machine and use method

A technology of basalt fiber and lignin fiber, which is applied in the direction of road repair, road, on-site coagulation pavement, etc., can solve the problems of increasing the difficulty and unsatisfactory construction of the mixing building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

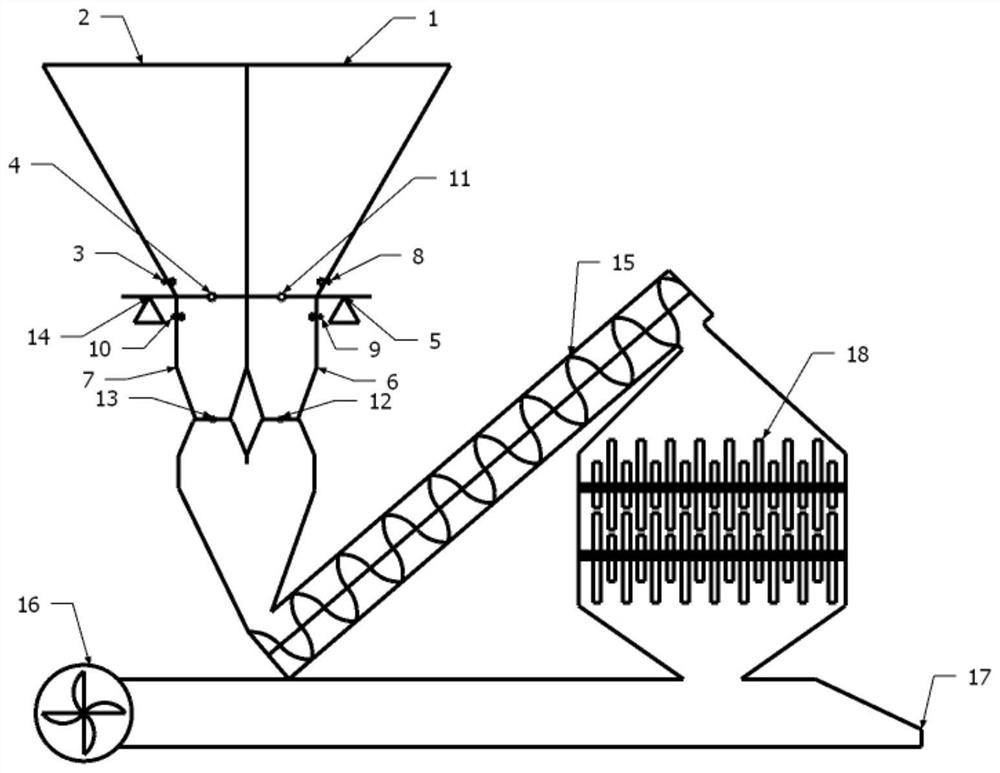

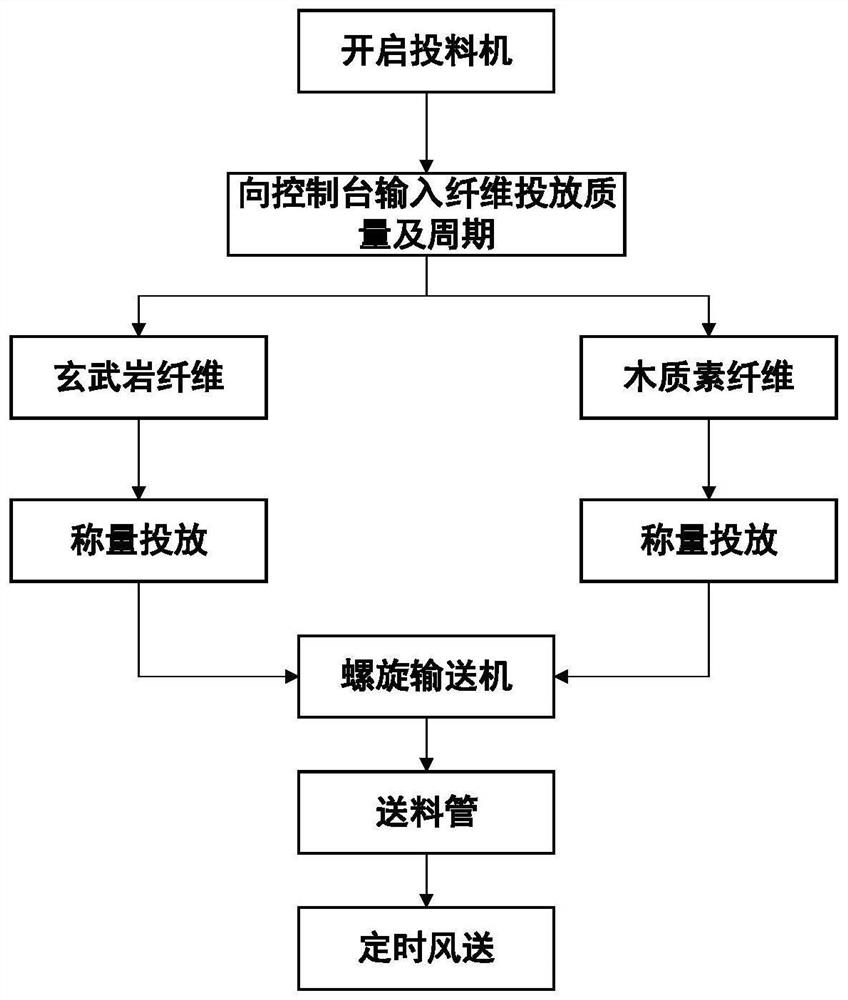

[0031] like figure 1 As shown, the multi-functional single compound granular lignin and basalt fiber feeder includes basalt fiber storage bin 1, granular lignin fiber storage bin 2, fiber storage bin level meter 3, and granular lignin fiber storage bin discharge Valve 4, basalt fiber weighing sensor 5, basalt fiber measuring chamber 6, granular lignin fiber measuring chamber 7, basalt fiber storage bin level gauge 8, basalt fiber measuring chamber level gauge 9, granular lignin fiber measuring chamber material Position gauge 10, basalt fiber storage bin discharge valve 11, basalt fiber metering chamber discharge valve 12, particle lignin fiber metering chamber discharge valve 13, particle lignin fiber weighing sensor 14, screw conveyor 15, air blower 16, Outlet 17, fiber fluffer 18. The above components constitute a fiber storage system, a fiber delivery system, a fiber fluffing system and a control system. Among them, the fiber storage bins 1 and 2 are connected to the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com