Compression Elastic Metal Cage Mandrel

A compressive elastic, metal technology, applied in the field of compressive elastic metal cage core mold, can solve the problems of reducing the seismic force of the core mold, easy to produce slurry leakage, damage, etc., achieve better coverage and filling density, and enhance shock resistance. and anti-compression, prevent structural damage and deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

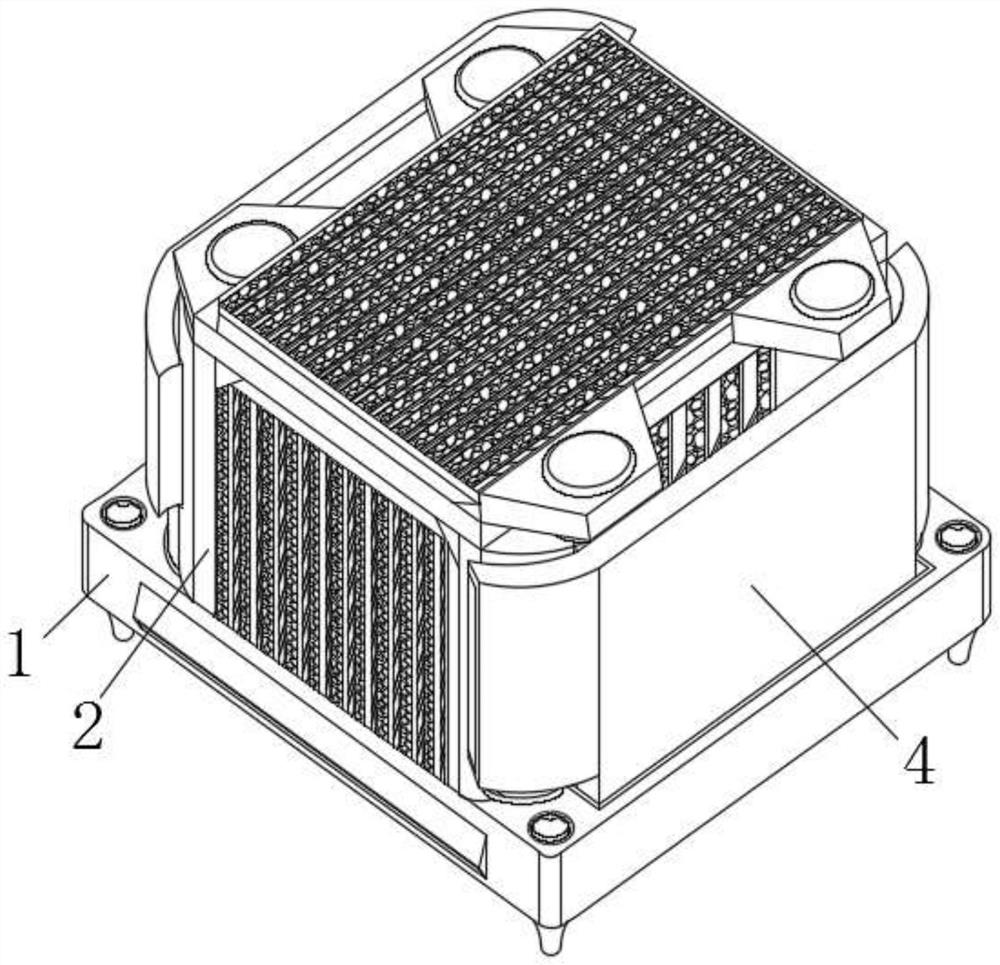

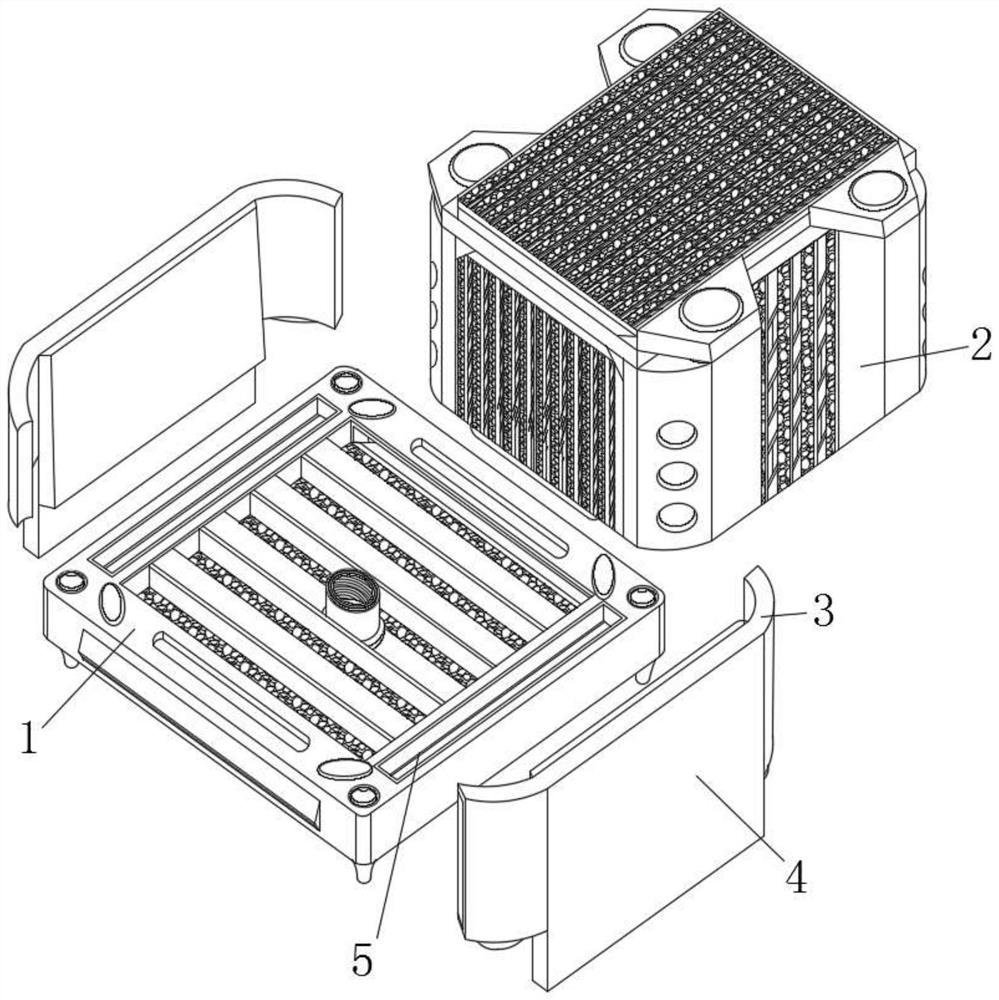

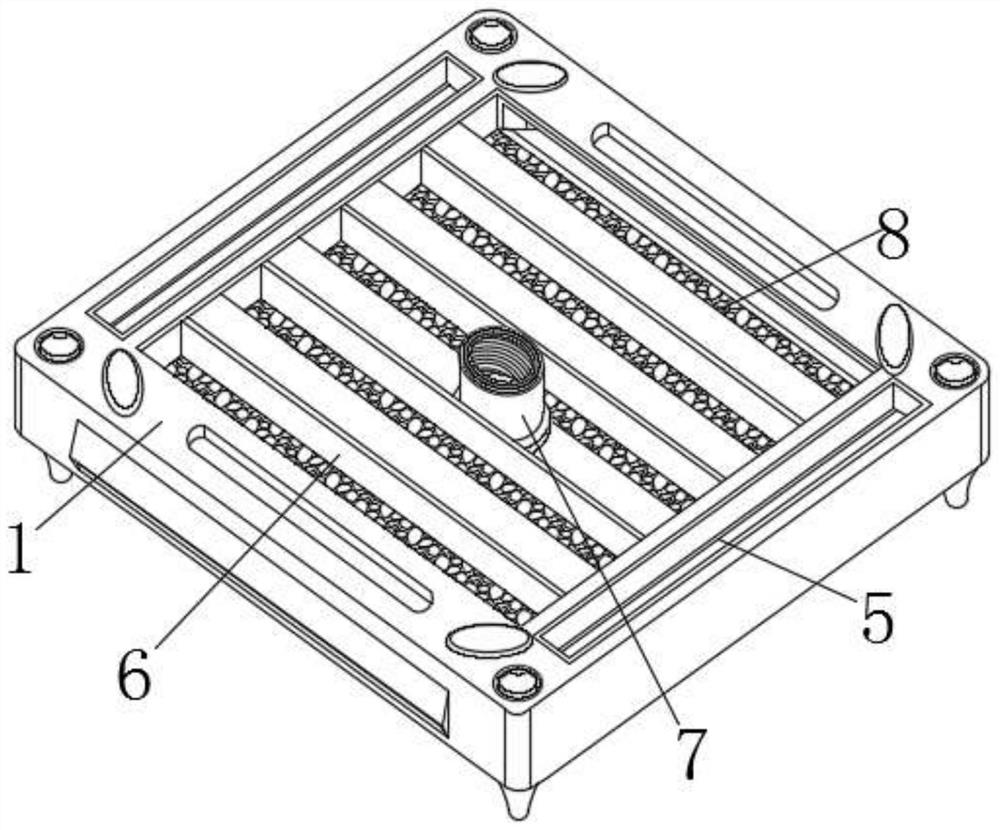

[0037] Example 1, as Figure 1-4 As shown, during the splicing of the box base 1 and the metal mesh box body 2, the metal mesh box body 2 is pre-joined with the box base 1 through the structural cooperation of the butt groove and the butt plate, and then the reinforcement plate 4 and the pre-embedded slot 5 are clamped. The combination and fixation promotes the overall bonding of the reinforcing plate 4 with the arc-shaped bonding plate 3 and the side reinforcement beams 10 on the outside of the metal mesh box body 2, so as to fix the spliced metal mesh box body 2 to prevent the metal mesh box body 2 from being biased. Dislocation increases the structural strength of the device assembly. When the upper mandrel 9 and the lower mandrel 8 are pouring concrete, the penetration of the lower mandrel 8 and the connection and cooperation of the through grooves can facilitate the uniform laying of the concrete on the grooves 6. On the inside, increase the pouring effect of concrete. ...

Embodiment 2

[0038] Example 2, as Figure 5-7 As shown in the figure, when the construction personnel step on the top of the metal mesh box body 2 and the upper core mold 9, the connection and cooperation between the upper core mold 9 and the fixed plate 113 force the spring 115 and the compression block 114 below the fixed plate 113. Interlocked with each other to form an elastic buffering and shock absorption function, and the surfaces of the fitting plate 112 and the buffer plate 111 above the fixing plate 113 are fitted with mutually matching card grooves to contact and fit the shock-absorbing balls, so that the fixing plate 113 can reduce the elastic buffering effect. A layer of reset and compressive effect is applied under the linkage of the shock to increase the stability of the structure, so that the four sets of flange beams 11 and the surface of the upper core mold 9 form an elastic platform. Under the action of the elastic platform , so that the impact force and stepping pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com