Industrial robot base convenient to install

A technology of industrial robots and bases, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of laborious installation, time-consuming and laborious, etc., and achieve the effects of preventing elastic failure, facilitating installation, and preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

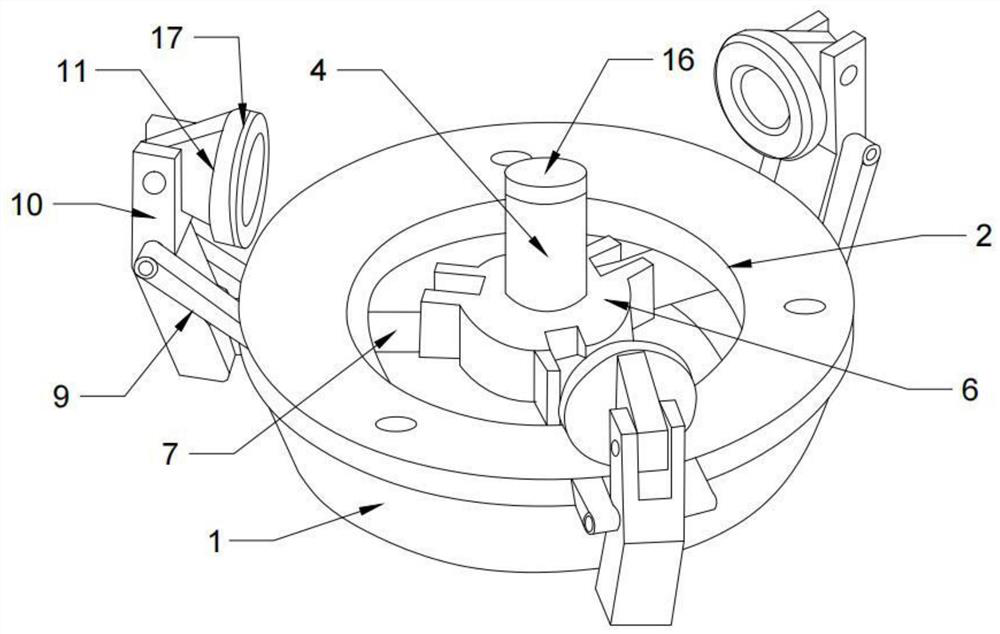

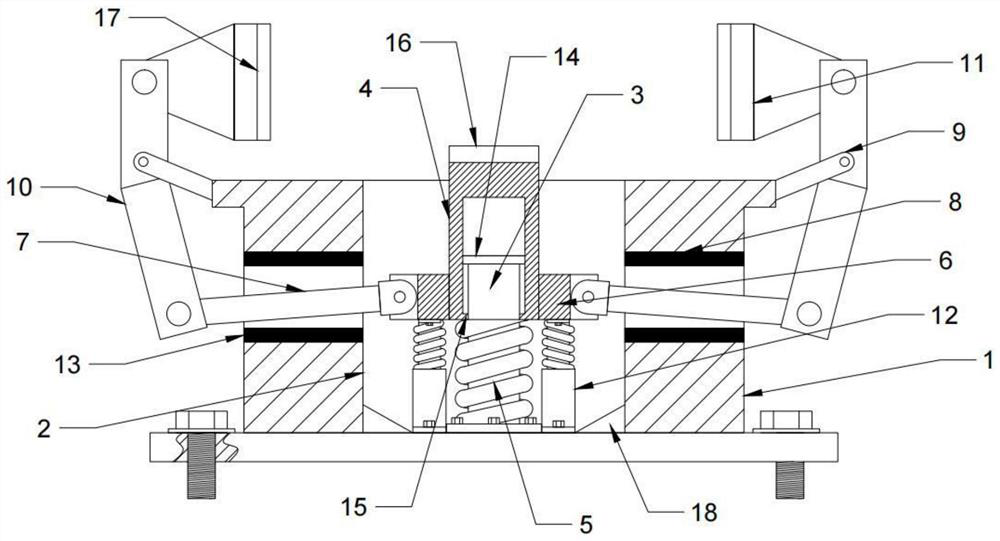

[0016] The present invention will be further described below with reference to the accompanying drawings.

[0017] Join figure 1 Adherent figure 2 An industrial robot for easy-to-mover, including a seat 1, and a cylindrical groove 2 is opened in the middle of the seat 1, and the column groove 2 is fixed in the middle of the bottom surface of the cylinder to fix the column 3, the column 3 Upper Sliding Conditions There is a lower press 4, and the column 3 is connected to a reset spring 5 located below the lower press 4, and the lower end is integrally formed with a hinge 6, the hinge plate. 6 Side on the side, there are several links 7, and a plurality of through holes 8 are uniformly opened on the side surface of the seat 1, and the support rod 9 is integrally formed on the upper side of the seat 1, each pair of support rods. 9 Turn a pressure rod 10 between the upper end, the link 7 is hinged to the lower end of the pressure rod 10 through the other end of the through hole 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com