Optical debugging vehicle platform

An optical and platform technology, applied in the field of on-board optical display equipment, can solve problems such as the inability to take into account the stability of the cockpit space and the rational use of the head-up display equipment, the inability to meet the road measurement requirements of the on-board head-up display equipment, and the effect of the use of the on-board head-up display equipment. , to achieve the effect of compact structure, minimized attention and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

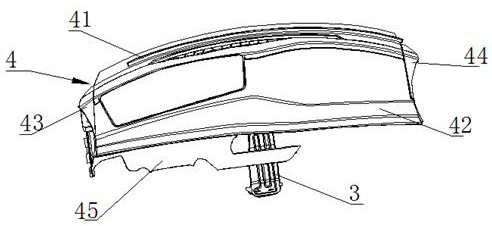

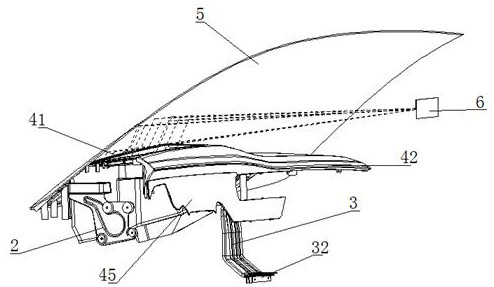

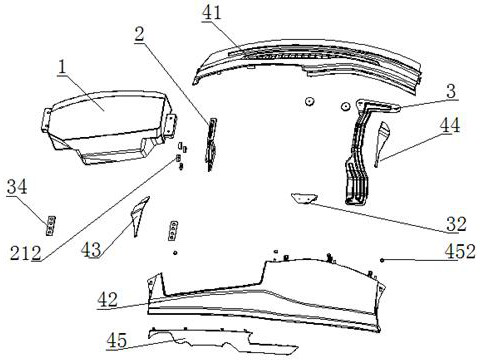

[0045] Such as Figure 1~Figure 15 , the present invention is an optical debugging vehicle platform, the optical debugging vehicle platform is refitted from a cockpit and an instrument panel of an automobile, and the automobile at least includes an A-pillar, an A-pillar panel, a cockpit, an instrument panel, and a main beam. The car platform includes an optical machine 1, a left bracket 2, a right bracket 3, a hatchback installation structure 4, a car windshield 5, and a virtual eye box position 6 behind the windshield;

[0046] The left bracket 2 includes a plate-shaped fixing portion 21 at the lower end, and the plate-shaped fixing portion is formed with a plurality of screw holes 211, and the left bracket is fixed on the A-pillar by setting bolts in the screw holes of the plate-shaped fixing portion. The upper end of the plate-shaped fixing portion extends rightward to a horizontal flange 22 with front and rear bar-shaped screw holes 221. The right bracket 3 is shaped to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com