Manual grinding and polishing microsection auxiliary set and auxiliary tool

A technology of metallographic sectioning and auxiliary tools, applied in the direction of measuring devices, sampling, instruments, etc., can solve the problems of small size, influence on observation and analysis, inconvenient to hold, etc., to ensure stable and consistent force, easy to observe and analyze, The effect of not easy to let go

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

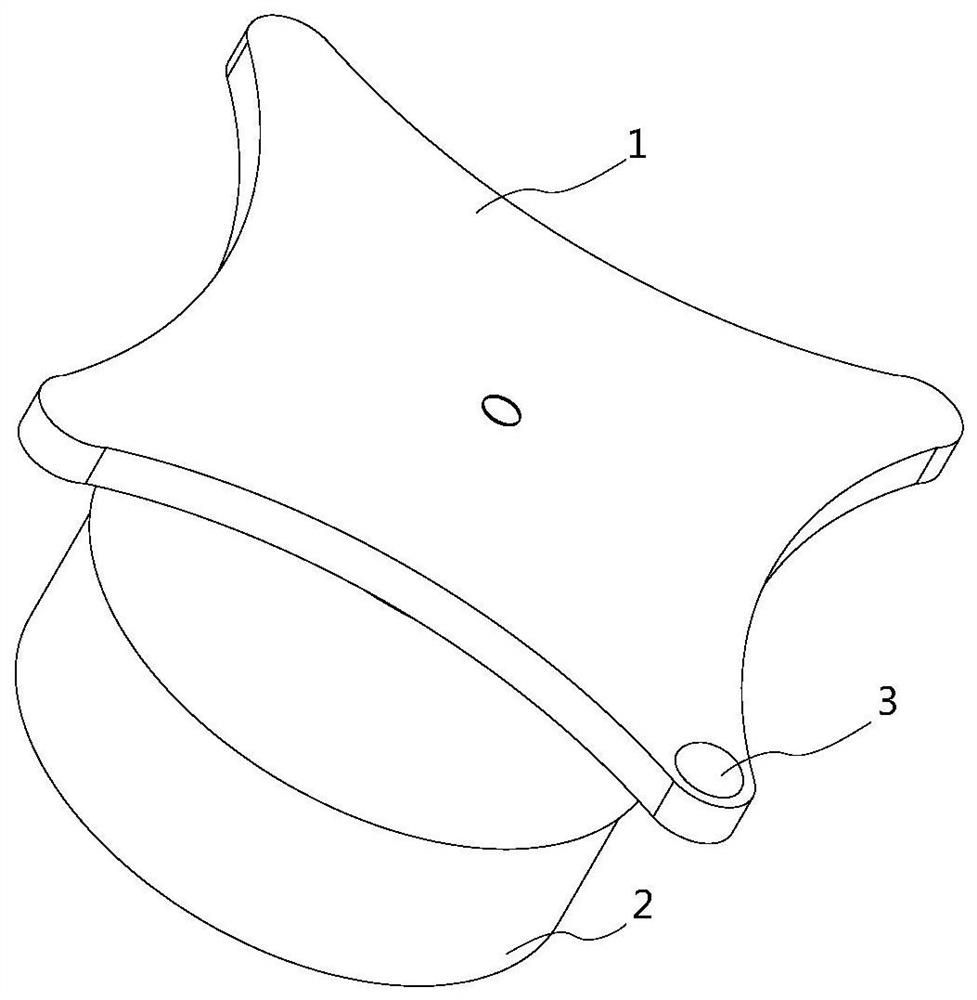

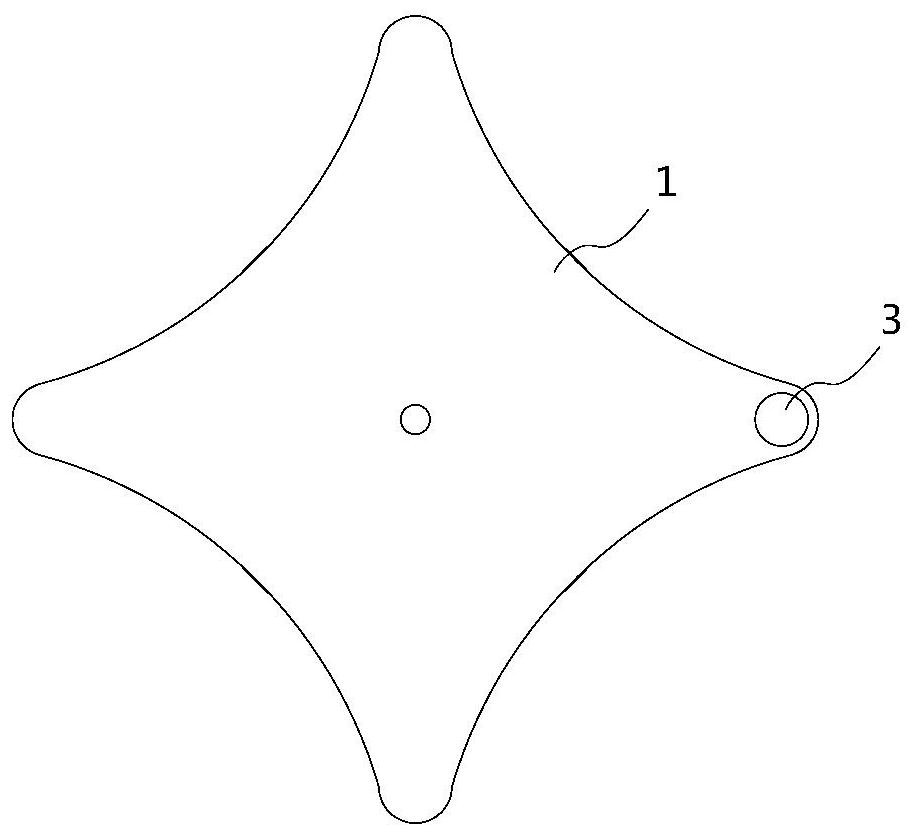

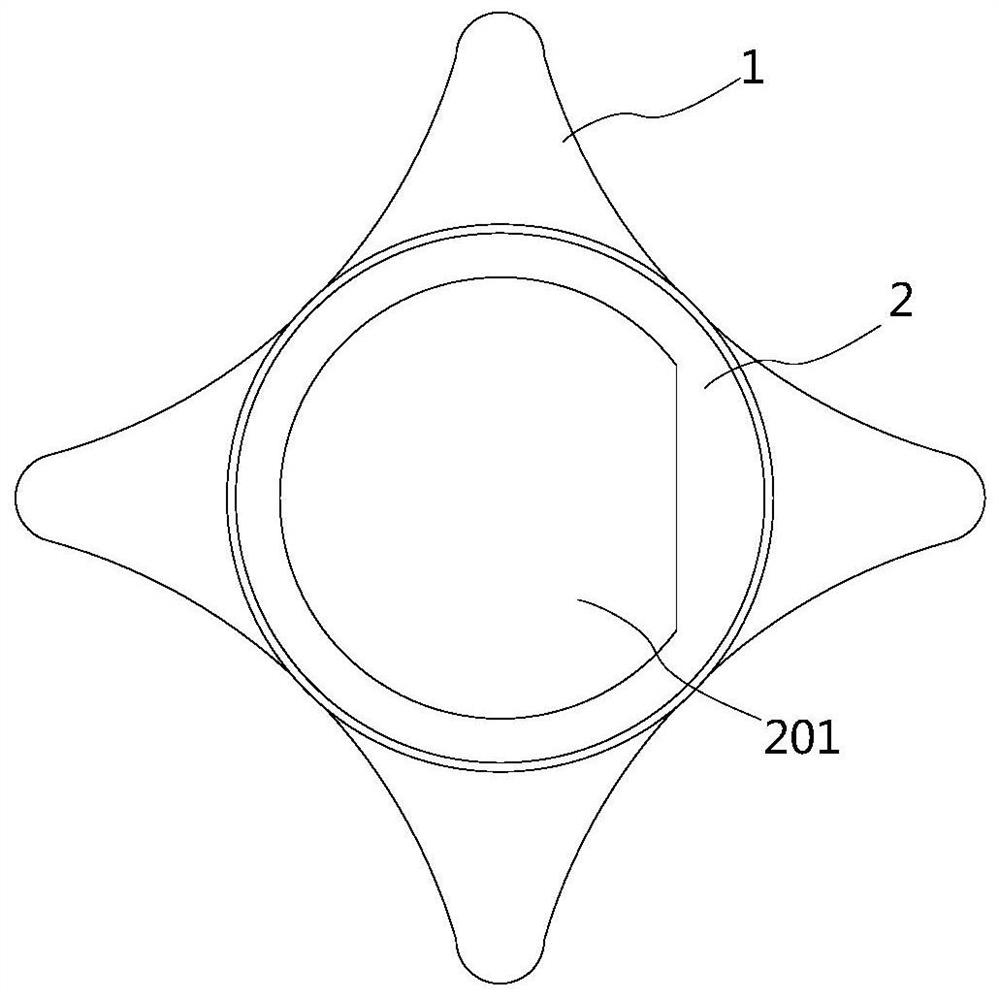

[0035] One of the cores of the present invention is to provide a manual grinding and polishing metallographic section auxiliary tool. The structure design of the manual grinding and polishing metallographic section auxiliary tool makes it easy to hold, and it is convenient to keep the metallographic section stable during grinding and polishing. Avoid hands-off and multiple plane problems during grinding and polishing.

[0036] Another core of the present invention is to provide a manual grinding and polishing metallographic section auxiliary set including the above-mentioned manual grinding and polishing metallographic section auxiliary tool.

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap