Double-plug electric connector

A connector and board-end connector technology, applied in the direction of conductive connection, connection, two-part connection device, etc., can solve the problems of line disconnection, easy force disconnection, affecting normal use, etc., to achieve high mechanical stability, wiring The effect of simple connection and firm wire connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

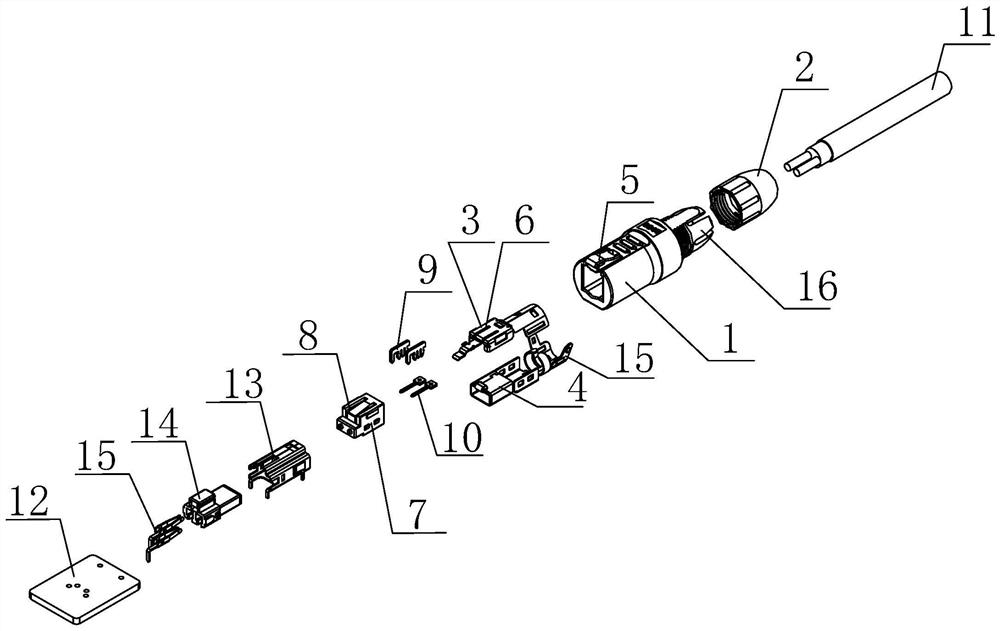

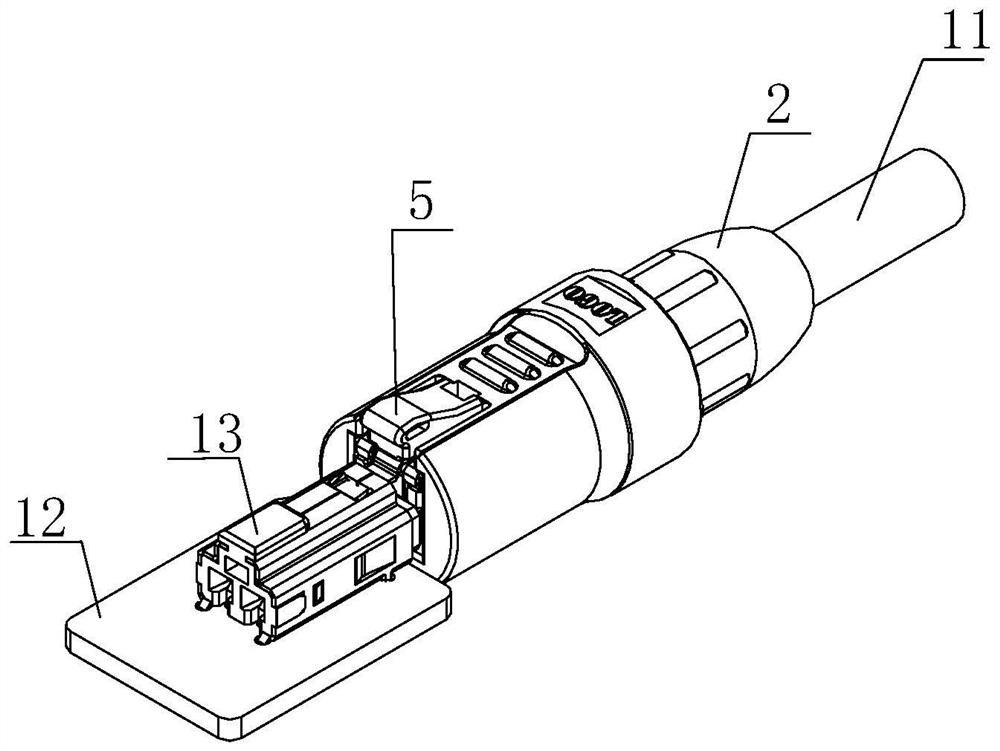

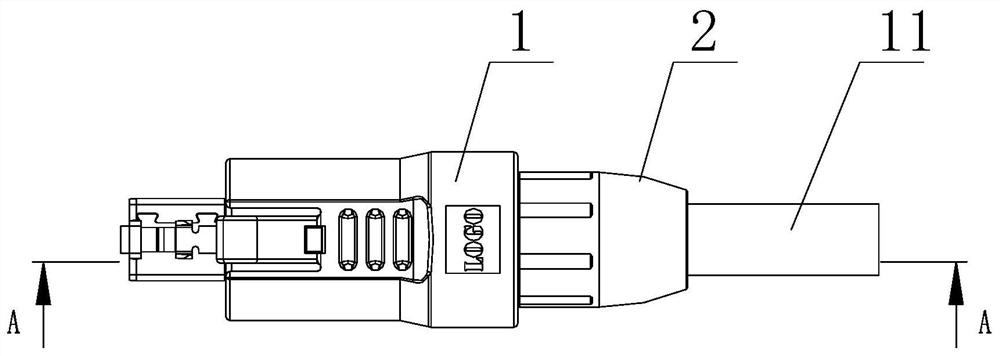

[0024] as attached Figure 1-5 As shown, a double-plug electrical connector includes a male end connector and a female end connector that are inserted into each other. The male end connector includes a cap body 1, and a cap ring is screwed to the rear of the cap body 1. 2. The inside of the hat body 1 is respectively provided with an upper shell 3 and a lower shell 4 which are engaged with each other, an elastic pressing part 5 is arranged above the hat body 1, and two sets of upper shells are arranged on the upper shell 3. Groove 6, the inside of the lower housing 4 is provided with a wire end connector body 7, and the wire end connector body 7 is provided with two sets of lower grooves 8 corresponding to the upper groove 6, corresponding to The upper groove 6 and the lower groove 8 are provided with a wire-end metal connecting piece 9, the upper edge of the wire-end metal connecting piece 9 is facing the lower end of the elastic pressing portion 5, and the wire-end metal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com