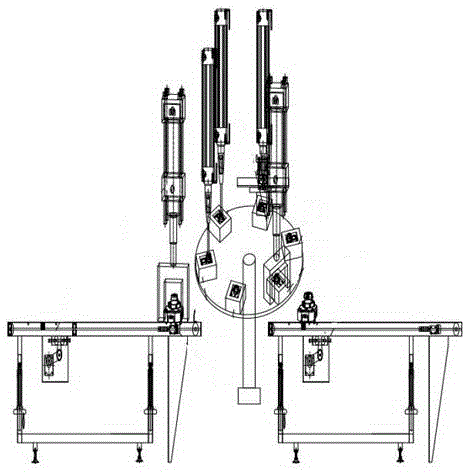

Automatic assembling machine

An automatic assembly machine and automatic assembly technology, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of not taking product inspection into account, product quality cannot be guaranteed, and unfavorable market promotion, etc., to ensure normal operation and guarantee Accuracy and safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

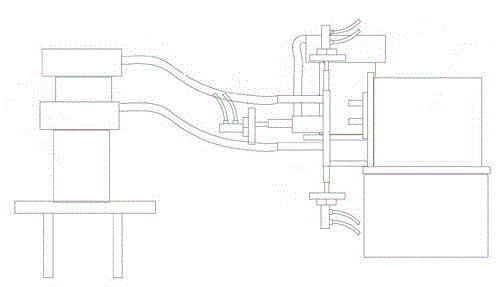

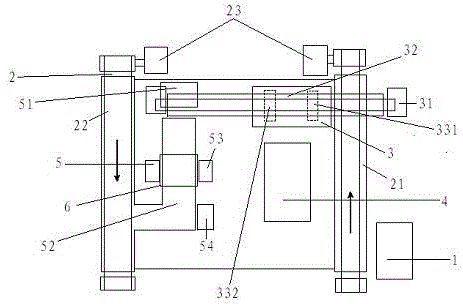

Embodiment 1

[0029] Place the workpiece to be processed on the transmission mechanism, and the product conveyor belt drives the workpiece to move forward. When the sensor on the up and down moving device 23 senses that the workpiece moves to a predetermined position, the electrical control cabinet 1 controls the up and down moving device 23 to move down and drive The guide rail 32 fixed on it descends, and the grabber installed on the guide rail 32 descends thereupon to grab the workpiece to be processed. Since the grabber includes the first gripper 331 and the second gripper 332, The distance between the first gripper 331 and the second gripper 332 is 1 / 2 of the guide rail 32, and because the second workpiece placement platform of the rubber-covering mechanism 4 and the center of the guide rail 32 of the grasping mechanism 3 Correspondingly, when the grabber grabs down, the workpieces located on the product input belt 21 and the second workpiece placement table can be grabbed and moved to ...

Embodiment 2

[0033] If the workpiece detected by the detection device 53 is unqualified, the defective product grasping mechanism 63 is activated, and the gripper grabs down to take out the defective workpiece from the detection channel 52 and moves it up. After the gripper moves to the top of the slide plate according to the direction of the guide groove, When the gripper is released, the defective workpiece slides down into the recycling box, avoiding the confusion of qualified and unqualified products, reducing the manual inspection process, reducing production costs and effectively improving product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com