Servo valve electromagnetic zero position automatic accurate quantification regulation and control device and method

A control device, servo valve technology, applied in the direction of measuring devices, electromechanical devices, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with embodiment.

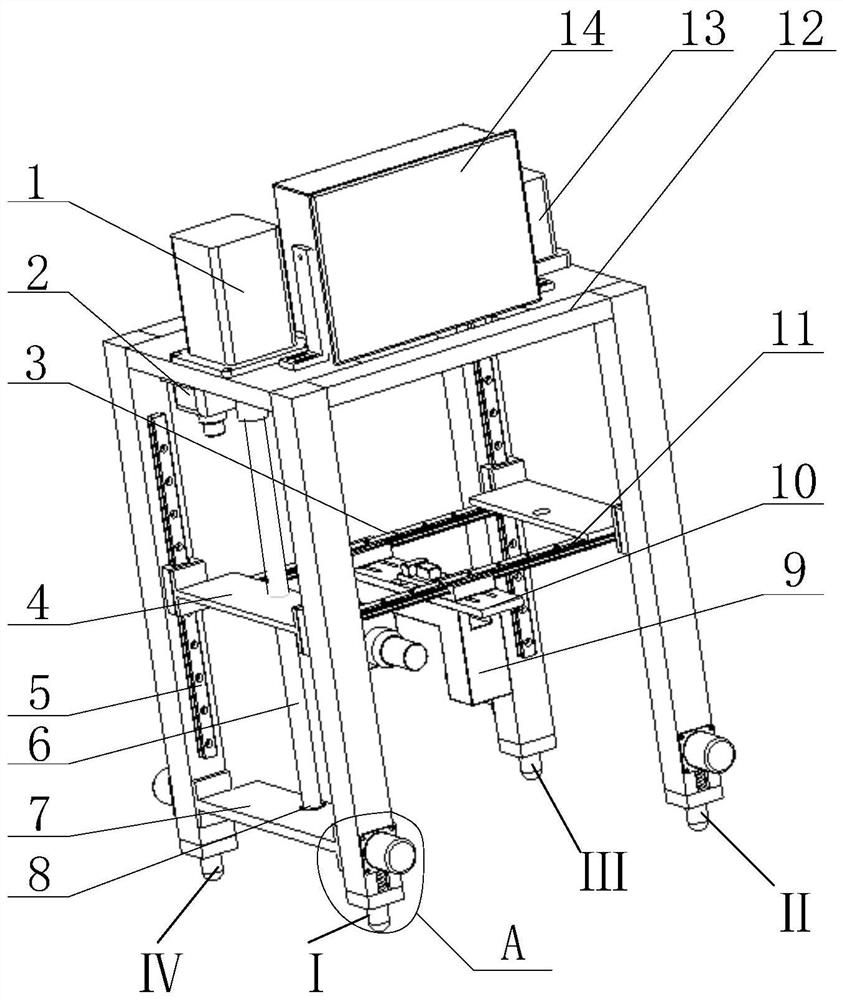

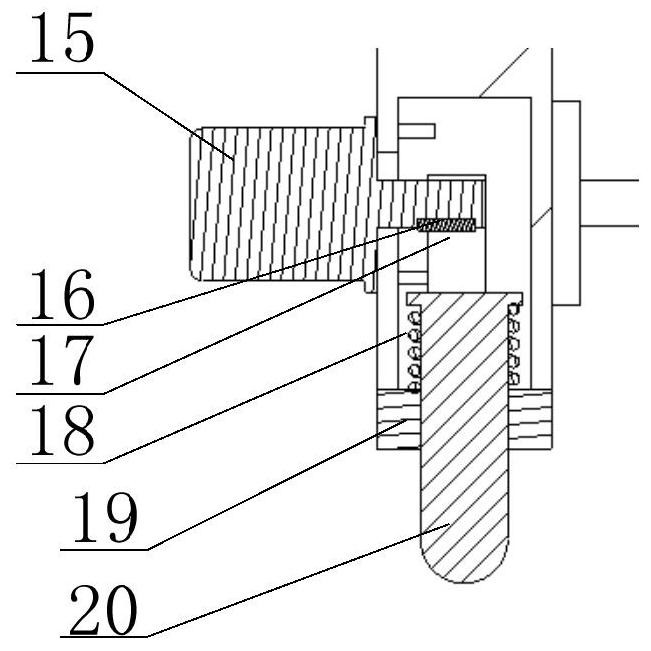

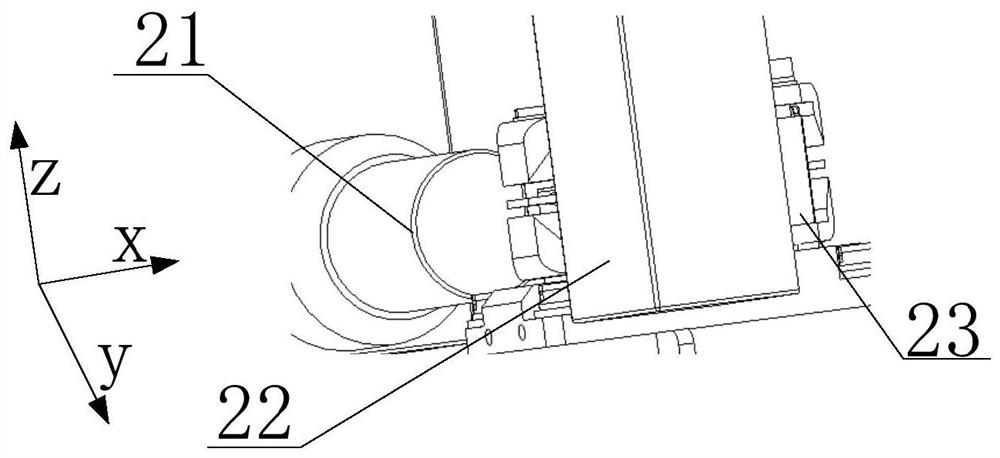

[0045] Such as Figure 1-3 As shown, the longitudinal position adjustment process: the upper computer sends a command signal, the lifting control motor 1 drives the rotation of the lifting screw 6, which can drive the longitudinal position of the lifting plate 4, and the laser displacement sensor 2 generates a feedback signal, so that the lifting adjustment forms a position closed-loop control , so as to automatically, quickly and accurately track the longitudinal position of the beam sensor 9 . In order to ensure the stability of the screw rotation, a directional bearing 8 is provided at its end; the four longitudinal adjustment slide rails 5 reduce the possibility of lifting stagnation and ensure the flexibility of movement.

[0046] Such as Figure 1-3 As shown, the horizontal position adjustment process: the upper computer sends out a command signal, the inclination adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com