A rapid continuous automatic drilling machine and drilling method

A drilling machine, automatic technology, applied in drilling/drilling equipment, boring/drilling, metal processing machinery parts, etc., can solve the problems of high scrap rate, low efficiency, time-consuming, etc. The effect of saving human resources and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

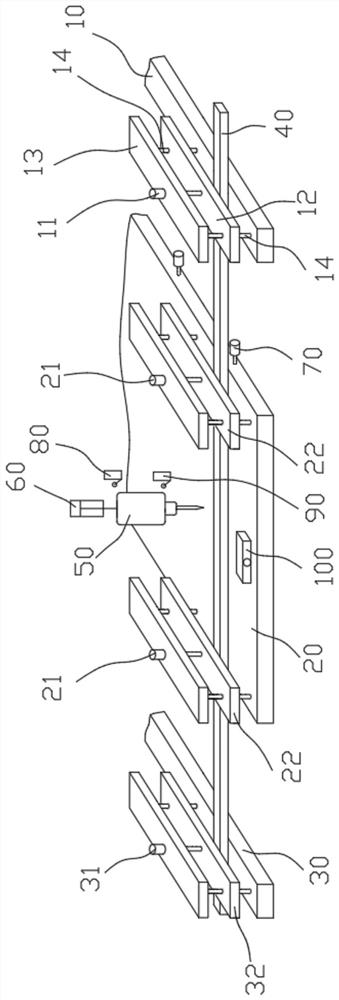

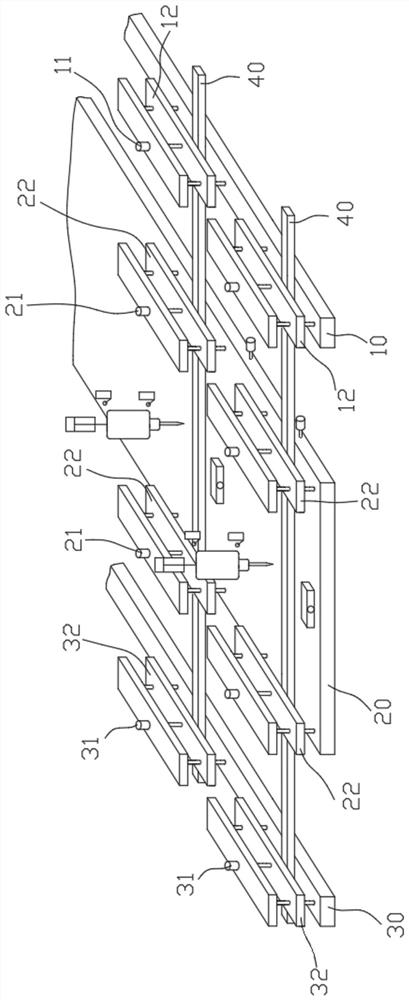

[0024] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0025] like Figure 1-3 As shown, the rapid continuous automatic drilling machine of this embodiment includes a front base 10, an intermediate base 20, a rear base 30, a pneumatic drill 50, a drill bit pressing cylinder 60 and a push cylinder 70, and the intermediate base 20 is arranged on the Between the front base 10 and the rear base 30 , the two ends of the elongated workpiece 40 are placed on the front base 10 and the rear base 30 respectively, and the middle of the elongated workpiece 40 is placed on the middle base 20 , the top of the front base 10 is fixed by the first bracket, the front cylinder 11 is fixed, and the piston rod of the front cylinder 11 drives the front pressure plate 12 to compress or loosen the long workpiece 40; the top of the rear base 30 is fixed by the second bracket. The cylinder 31, the second piston rod of the rear cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com