Unattended Automatic Tunneling System for Gas High Outburst Roadway

A technology of power system and roadway, applied in the field of excavation system, can solve problems such as unsafe production, coal and gas outburst accidents, casualties, etc., and achieve the effects of good mobility, flexible operation and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

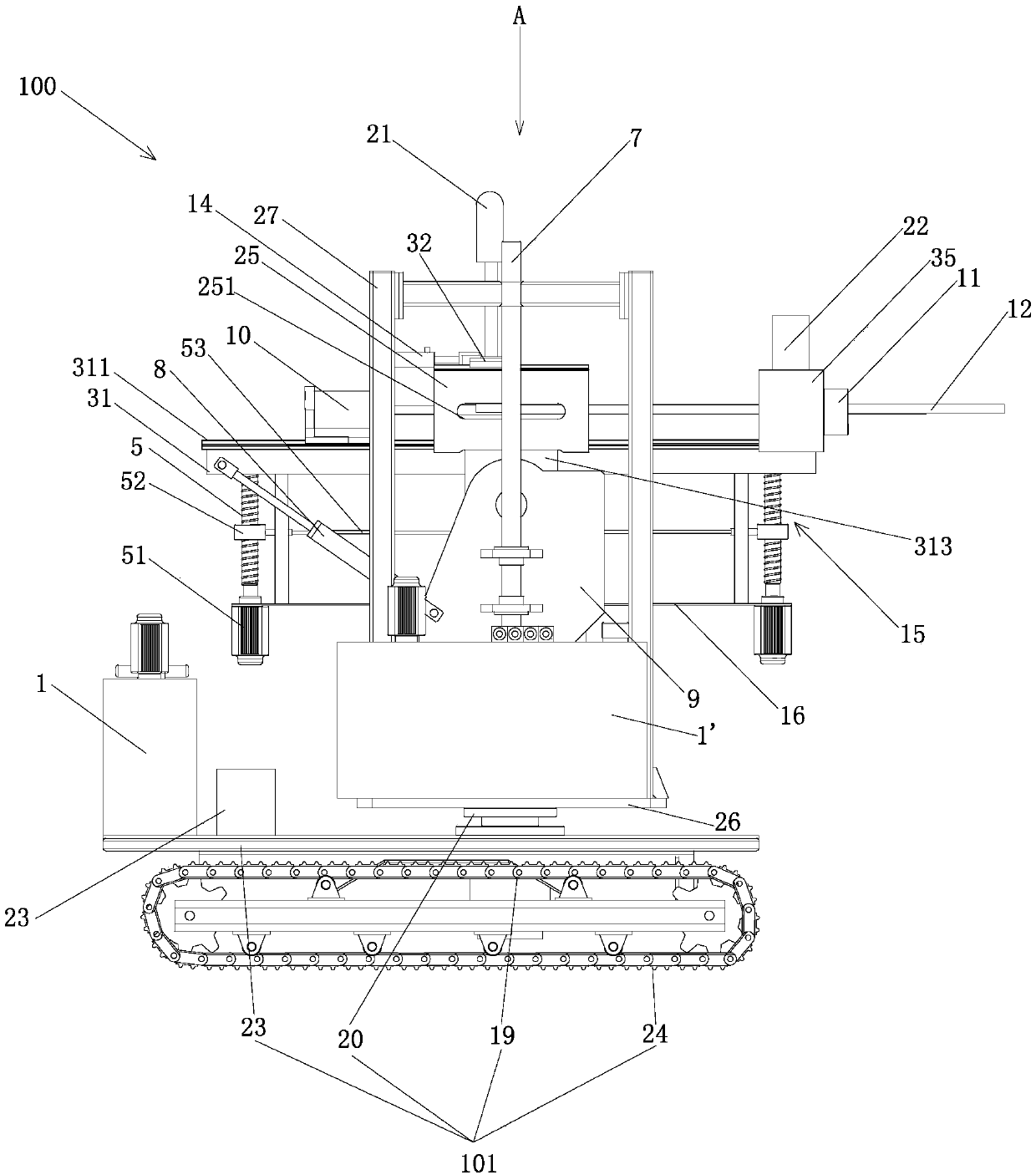

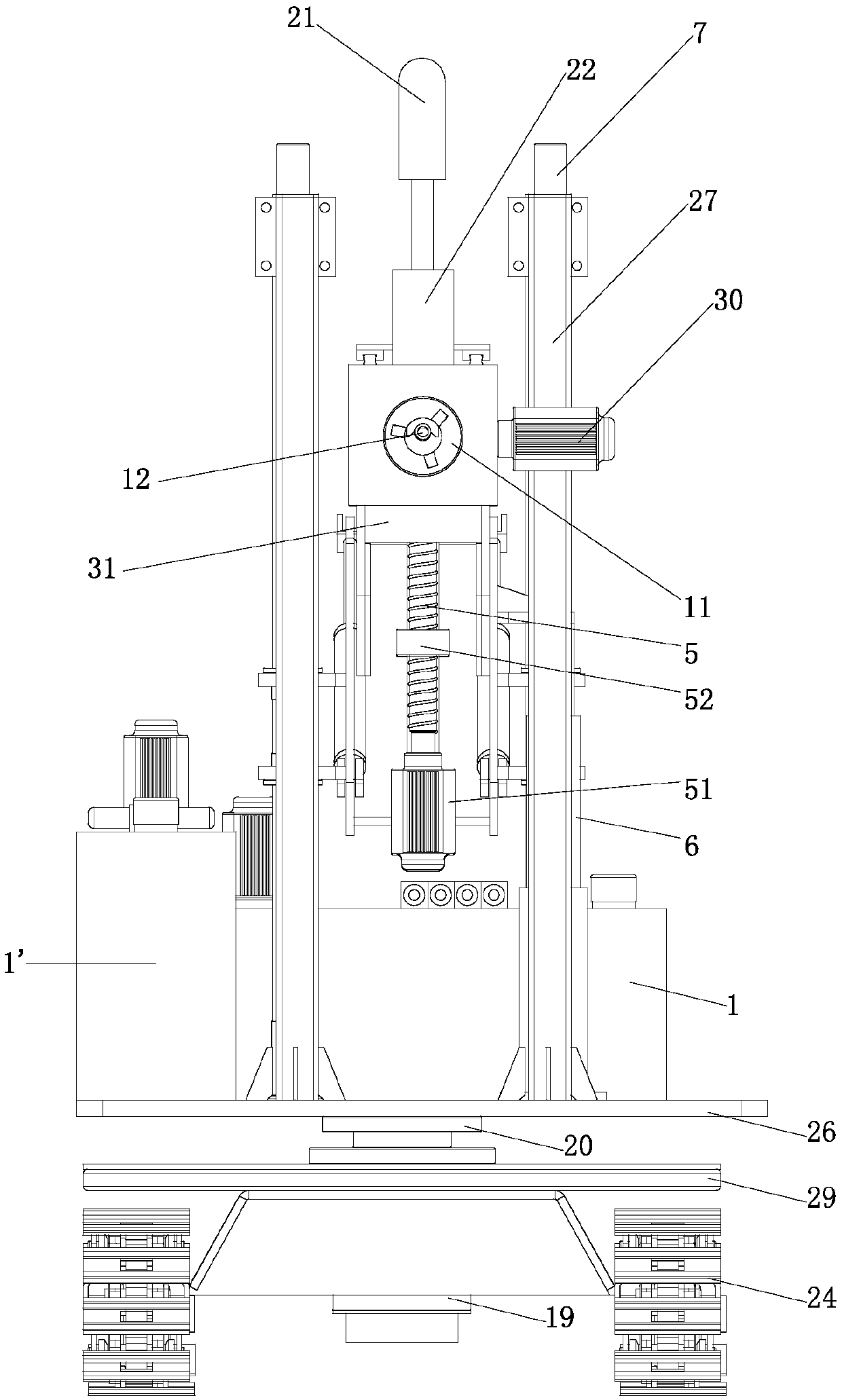

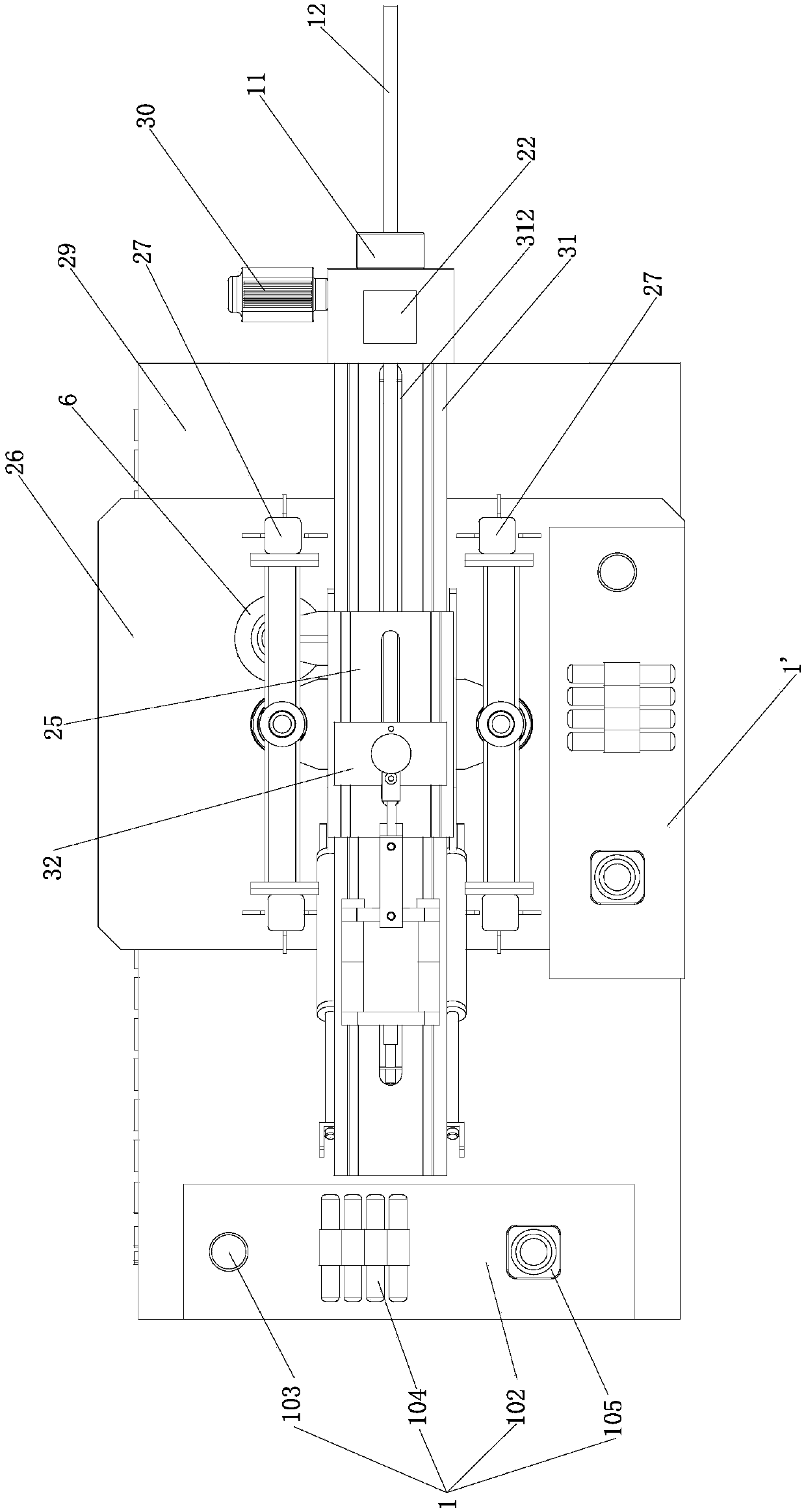

[0027] Such as Figure 1 to Figure 5 As shown, the unattended automatic excavation system for high gas outburst roadways of the present invention includes a mining intelligent drilling vehicle 100, a remote control system for controlling the mining intelligent drilling vehicle 100, a laser locator and a rear omnidirectional camera 21, The front sensor module and the front camera 22, the on-board switchboard and the central controller 23, the remote control system includes the ground central control room, the underground seamless roaming base station and the optical fiber network linking the two, the mining intelligent drilling rig 100 includes the power system and The executive system driven by it, the power system includes a rear power system 1 and a side power system 1', the rear power system 1 is arranged on the upper rear part of the support platform 29, and the side power system 1' is arranged on the upper left of the support plate 26 On the side, the execution system inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com