A kind of antique building ash wood surface making old equipment

A technology for imitating antique buildings and old equipment, which is applied to the field of making old equipment on the surface of ash wood in antique buildings, which can solve the problems of affecting product quality and reducing the effect of old-fashioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

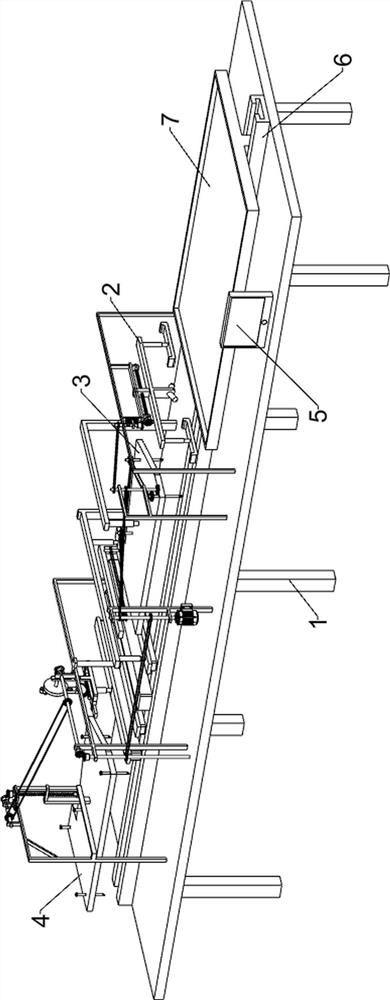

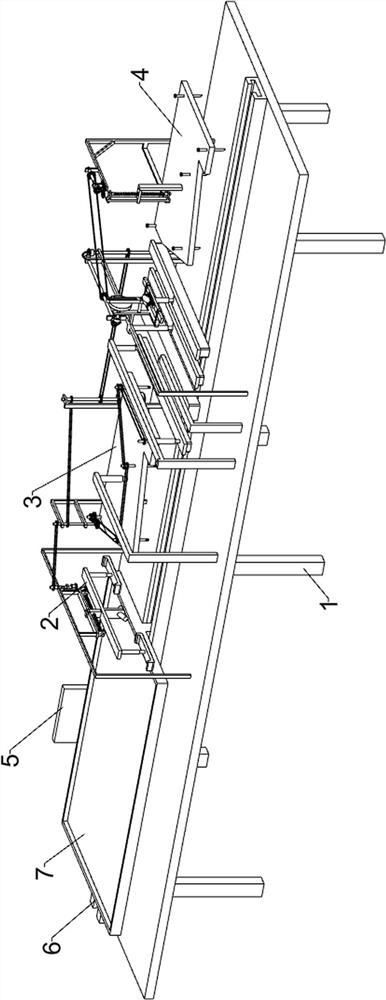

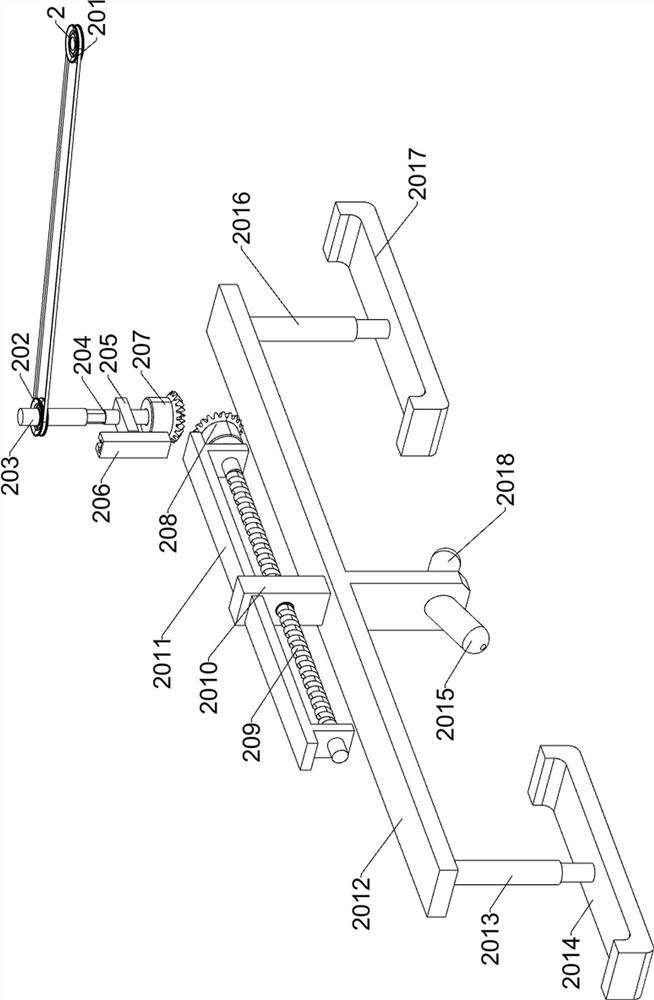

[0027] An antique building is used to make old equipment on the surface of ash wood, such as Figure 1-8 As shown, it includes a base frame 1, a grinding assembly 2, a perforation assembly 3, an oil brushing assembly 4, a control panel 5, a first electric sliding rail 6 and a first sliding plate 7; the base frame 1 is connected with the grinding assembly 2; the base frame 1 is connected with the perforation assembly 3; the bottom frame 1 is connected with the oil brushing assembly 4; the bottom frame 1 is connected with the control panel 5; the bottom frame 1 is connected with the first electric sliding rail 6; Connection; the perforation assembly 3 is connected with the oil brushing assembly 4; the first electric sliding rail 6 is slidably connected with the first sliding plate 7.

[0028] When preparing for work, place the device on a horizontal surface, turn on the power supply, and place the ash plank to be treated inside the first sliding plate 7, then control the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com