Intelligent assembly line for gearbox planetary system and assembly process of intelligent assembly line

An assembly line and planetary system technology, applied in assembly machines, metal processing equipment, sorting, etc., can solve the problems of high labor costs, high costs, and long time consumption, and achieve time-saving and labor-saving mechanical operations and a high qualified rate of finished products , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

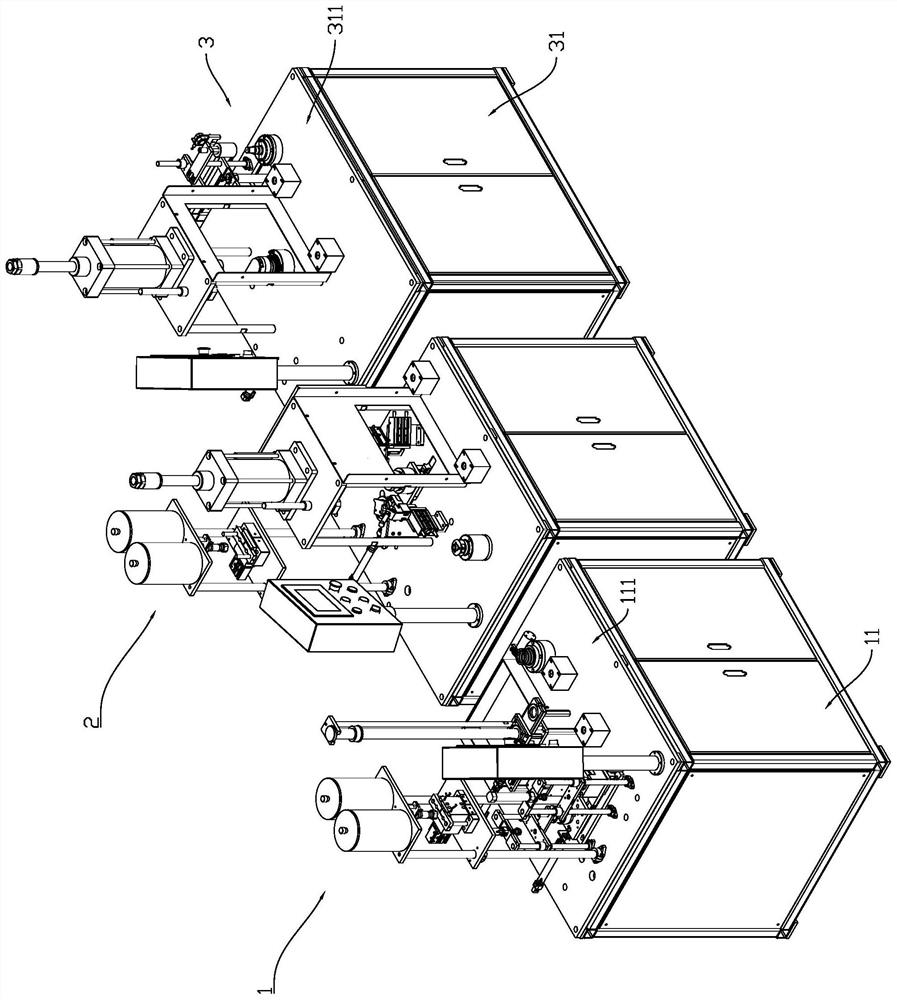

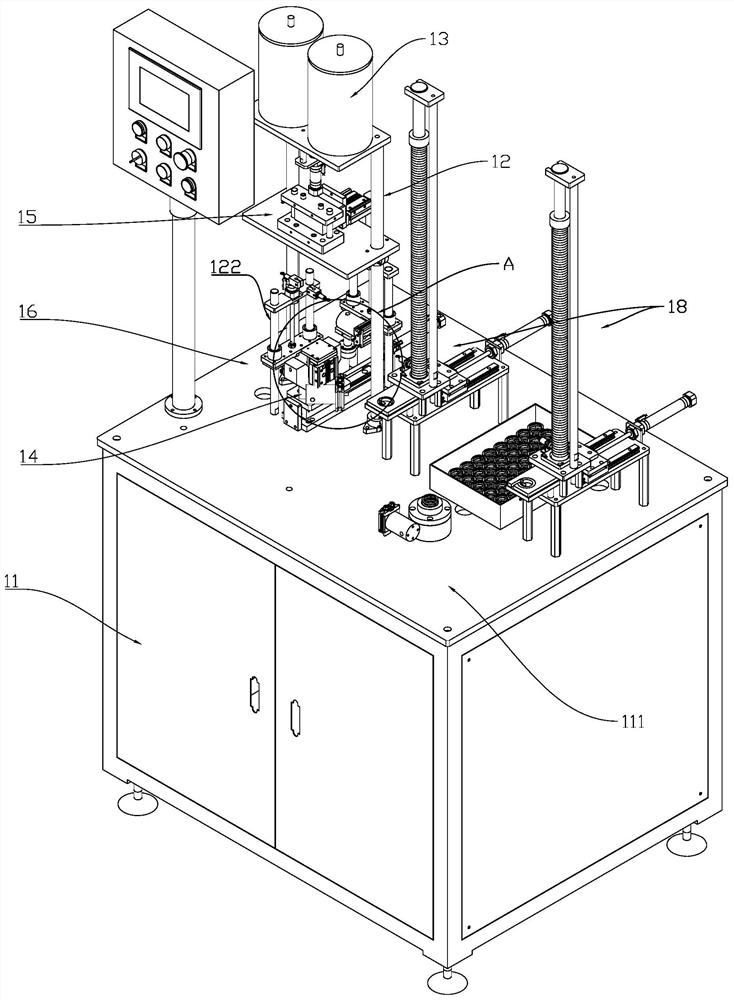

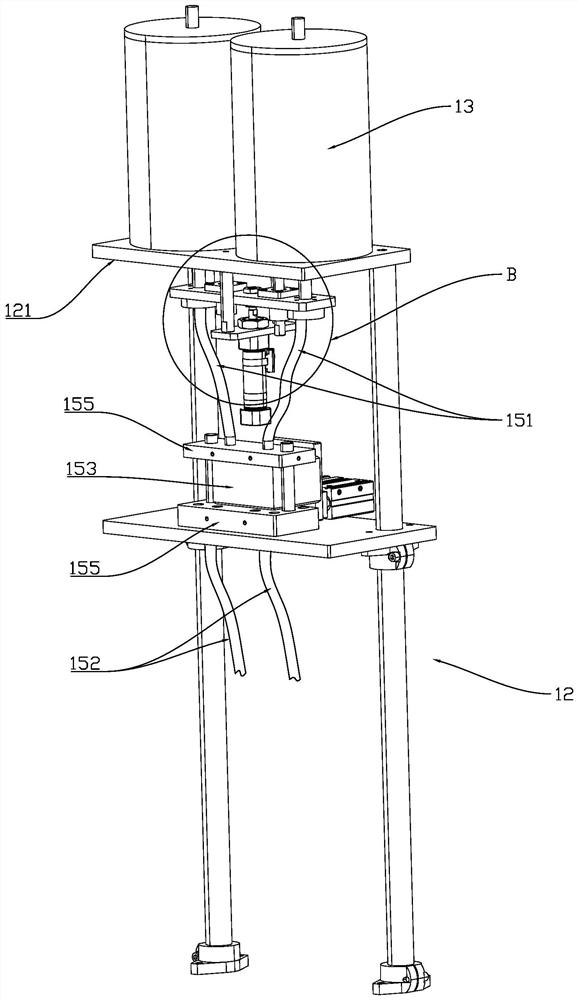

[0067] The present invention will be further described below with specific embodiment, see Figure 1-Figure 27 .

[0068] An intelligent assembly line for a gearbox planetary system, such as figure 1 As shown, it includes the first steel ball assembly machine 1 for installing steel balls on the gear box striking block, the second steel ball assembly machine 2 for installing steel balls on the planetary carrier spindle, and adding grease to the planetary carrier spindle and striking block The refueling device, the needle roller bearing pressing machine 3 for pressing the needle roller bearing on the main shaft of the planetary carrier, and the planetary carrier part feeder for conveying the planetary carrier parts. Wherein, the second steel ball assembly machine 2 for installing steel balls on the main shaft of the planet carrier is arranged between the first steel ball assembly machine 1 and the needle roller bearing pressing machine 3, and the first steel ball assembly machi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap