Laminating roller slip sheet with special structural design

A special structure, the technology of laminating rollers, applied in the field of tire processing, can solve the problems of cracking, restricting the transformation and development of the tire building process, and achieve the effect of reducing wear, strong practicability, and improving the pressing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

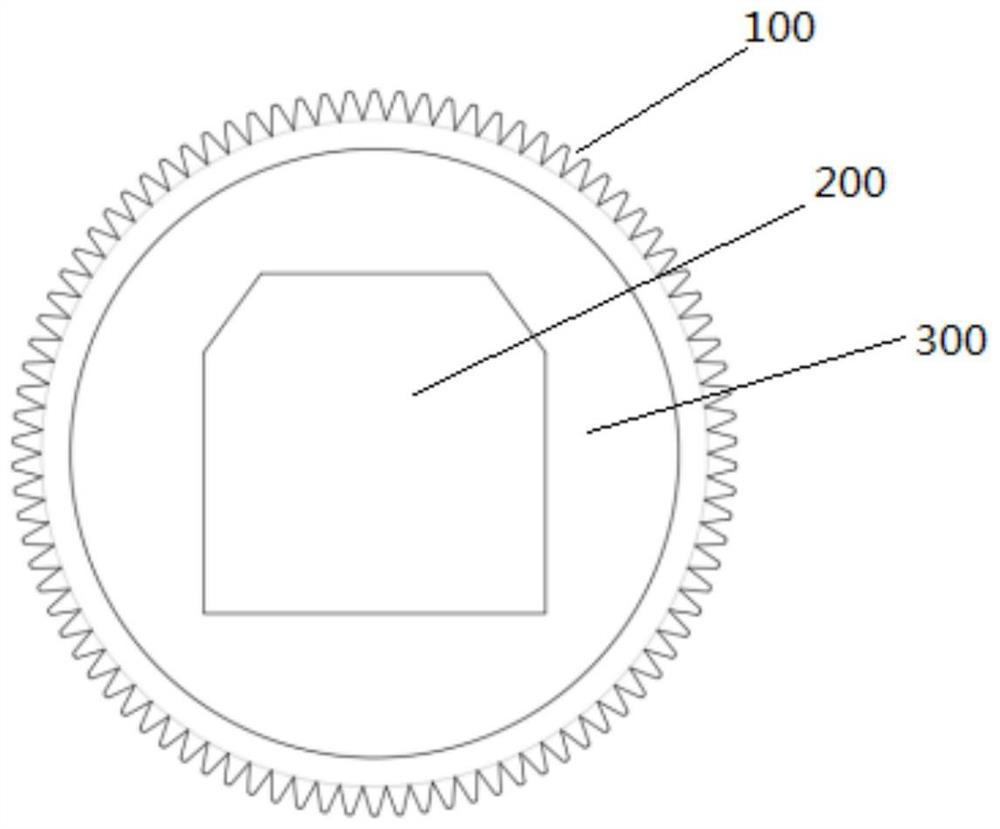

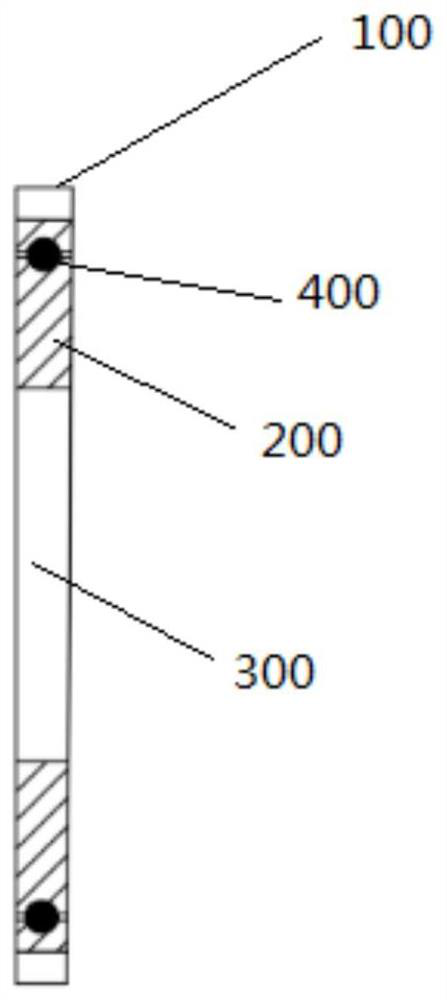

[0020] see Figure 1-2 , in the embodiment of the present invention, a laminating roller slide sheet with a special structural design includes an outer ring 100 and an inner ring 200, the outer ring 100 is installed on the outside of the inner ring 200, and there is a rotational connection between the two, and the The middle position of the inner ring 200 is provided with a card slot 300 for installation, and the 100 and 200 are rotationally connected by a ball mechanism. The installation groove, the installation groove and the transmission groove have constructed a ball groove that is convenient for placing the ball 400. The surface of the inner ring 200 is provided with a seal ring for sealing the installation groove to limit the position of the ball 400. The seal ring is connected to the inner ring 200 by bolts. The connection is fixed;

[0021] The outside of the outer ring 100 is provided with a toothed ring for tight contact with the tread to be pressed. The toothed rin...

Embodiment 2

[0024] The difference from Example 1 is that: the inner wall of the transmission groove and the installation groove is provided with a lubricating oil groove, which is convenient for applying lubricating oil, thereby effectively reducing wear, and the surface of the sealing ring is provided with at least one oil injection hole, and the oil injection hole It is connected with the lubricating oil tank, and the corresponding lubricating oil can be injected later as needed.

[0025] The working principle of the present invention is: the present invention constructs the ring gear that is used to press the tire on the outer side of the outer ring 100, utilizes the gear block on the ring gear to reduce the contact area between the slide plate and the tire as a whole, so that the slide plate and the tire The contact surface of the surface can generate greater pressure to achieve a better pressing effect, effectively avoid the opening of the joint, and improve the automatic pressing eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ring diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com