An auxiliary device for three-dimensional compensation and cutting of banknotes

An auxiliary device and a technology of making up for the difference, applied in the direction of metal processing, etc., can solve the problems of cutting quality and appearance quality, and achieve the effect of stable and reliable cutting quality, improving work efficiency, and eliminating hidden dangers of cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings.

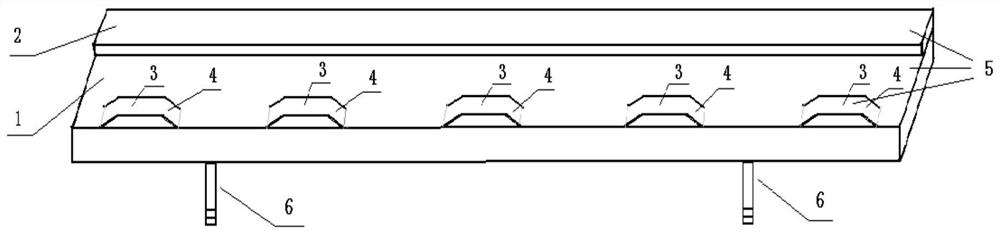

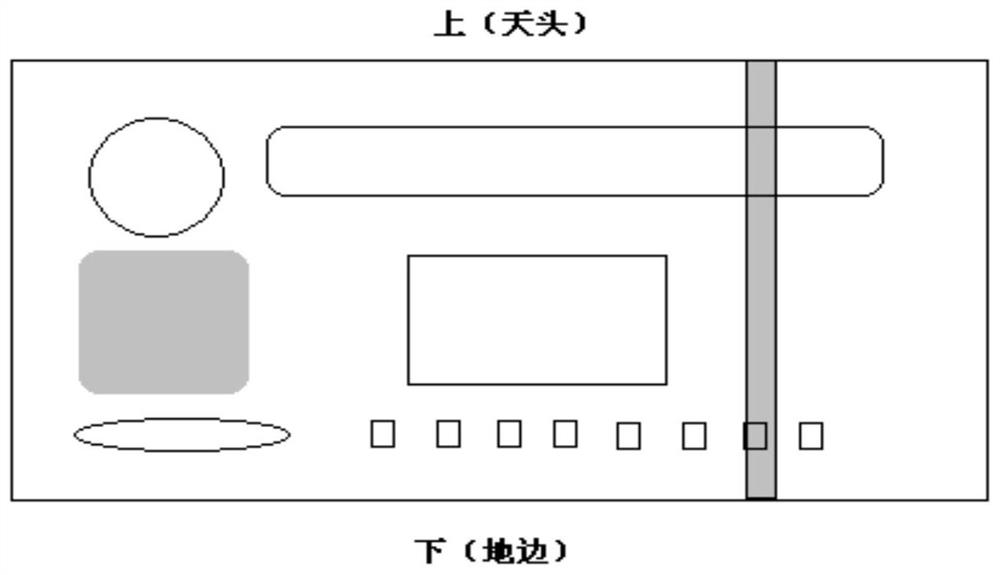

[0032] like figure 2 As shown, the auxiliary device for three-dimensional compensation and cutting of banknotes provided by the present invention comprises a substrate 1, a first compensation layer 2 (or a pressing protrusion) arranged on the base plate 1, a second compensation layer 3, and a Two fastening hooks 6 on both sides of the base plate 1 for mounting the entire auxiliary device on the paper press.

[0033] The first compensation layer 2 is arranged on one side of the upper surface of the substrate 1 and extends along the length direction of the substrate 1;

[0034] There are a plurality of second compensation layers 3, which are arranged on the other side of the upper surface of the substrate 1 opposite to the first compensation layer 2, and are distributed at intervals along the length direction of the substrate 1; Match the white edges of the multi-row cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com