Latticed heat sealing die of semi-fluid filling machine

A heat-sealing and filling machine technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve problems such as easy adhesion between molds and heat-sealing materials, weak heat-sealing, and easy cracking, and achieve Reduce product damage, reduce product loss, and improve equipment operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

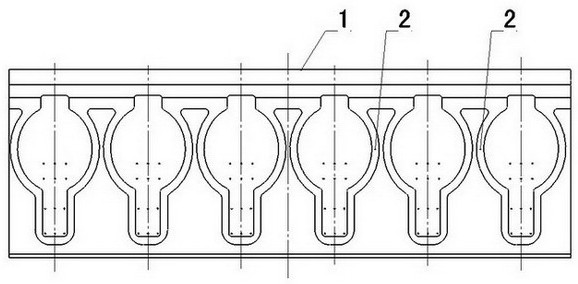

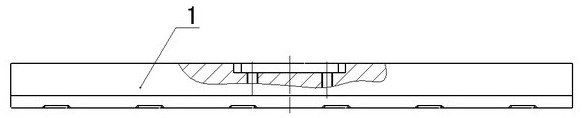

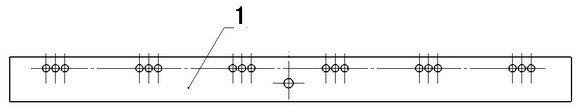

[0022] As shown in the accompanying drawings, the present invention includes a pair of soft package heat-sealing molds 1 and a pair of soft-package heat-sealing molds 4, that is, the soft-package heat-sealing mold 1 and the soft-package heat-sealing mold 4 are arranged in pairs , the structure and size of each pair of molds are the same, so that the two heat-sealing materials are heat-bonded together; there is a heat-sealing extrusion surface 2 on the heat-sealing mold 1 of the flexible package, and the shape of the heat-sealing extrusion surface 2 is not limited. Set according to the requirements of the product, there is a heat-sealing extrusion surface 5 on the heat-sealing mold 4 of the soft package body, and a mesh pattern is provided on the heat-sealing extrusion surface 2 and the heat-sealing extrusion surface 5, so that the heat-sealing extrusion surfaces 2 and 5 Form several small bumps to increase the local extrusion force on the heat-sealing material; the heat-sealing...

Embodiment 2

[0024] Its structure is the same as in Example 1, the only difference is that the heat-sealing extrusion surface 2 of the flexible package heat-sealing mold 1 has a mesh width of 1.2 mm, a depth of 0.2 mm, and an angle of 75° between the cutters. The included angle Ф is 75°; the width of the heat-sealing extrusion surface 5 of the soft package sealing heat-sealing mold 4 is 0.8 mm, the depth is 0.3 mm, the included angle of the tool is 135°, and the included angle Ф of the mesh is 135°.

Embodiment 3

[0026] Its structure is the same as in Example 1, the only difference is that the heat-sealing extrusion surface 2 of the flexible package heat-sealing mold 1 has a reticulate width of 0.8 mm, a depth of 0.3 mm, an included angle of the cutter of 135°, and a reticulated pattern of 0.8 mm. The included angle Ф is 135º; the width of the heat-sealing extrusion surface 5 of the flexible package sealing heat-sealing mold 4 is 0.6 mm, the depth is 0.1 mm, the included angle of the tool is 90º, and the included angle Ф of the mesh is 90º.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com