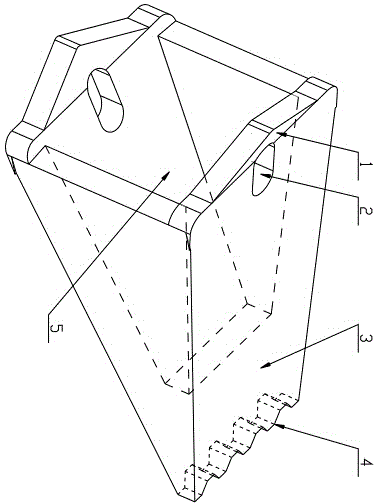

Cutting tooth with sawteeth for drill bit of pile driver

A cutting tooth and sawtooth technology, which is applied in the field of sawtooth cutting teeth for pile driver drill bits, can solve the problems of reduced cutting speed of sand and gravel, affecting the progress of construction, and reducing the pressure of sand and gravel layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0008] During construction, the machine drill bit is installed on the drill bit with sawtooth cutting teeth. Since the cutting teeth are provided with a guide plate 1, it is easy to assemble in place along the cavity 5, and the pin is inserted into the pin hole 2 for positioning. The waist trapezoidal sawtooth 4 is in contact with the sandstone layer at a certain angle. Under the pressure and rotation of the pile driver, the continuous cutting of the sandstone layer is realized. The sawtooth part of alloy cast steel is hard and wear-resistant, and it is partially in contact with the sandstone First of all, the hard surface of sand and gravel is destroyed to make it soft, and it is taken away by the plate body as a whole, and brought out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com