Demolding machine and demolding method thereof

The technology of a demoulding machine and a demoulding mechanism, which is applied in the field of demolding machines, can solve the problems of melting hot pot bottom material and difficult operation, and achieve the effects of improving production efficiency, improving production quality and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

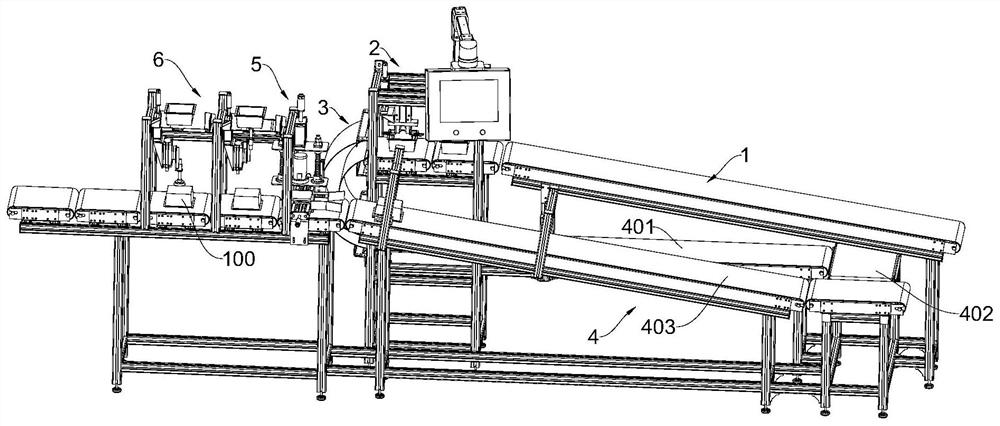

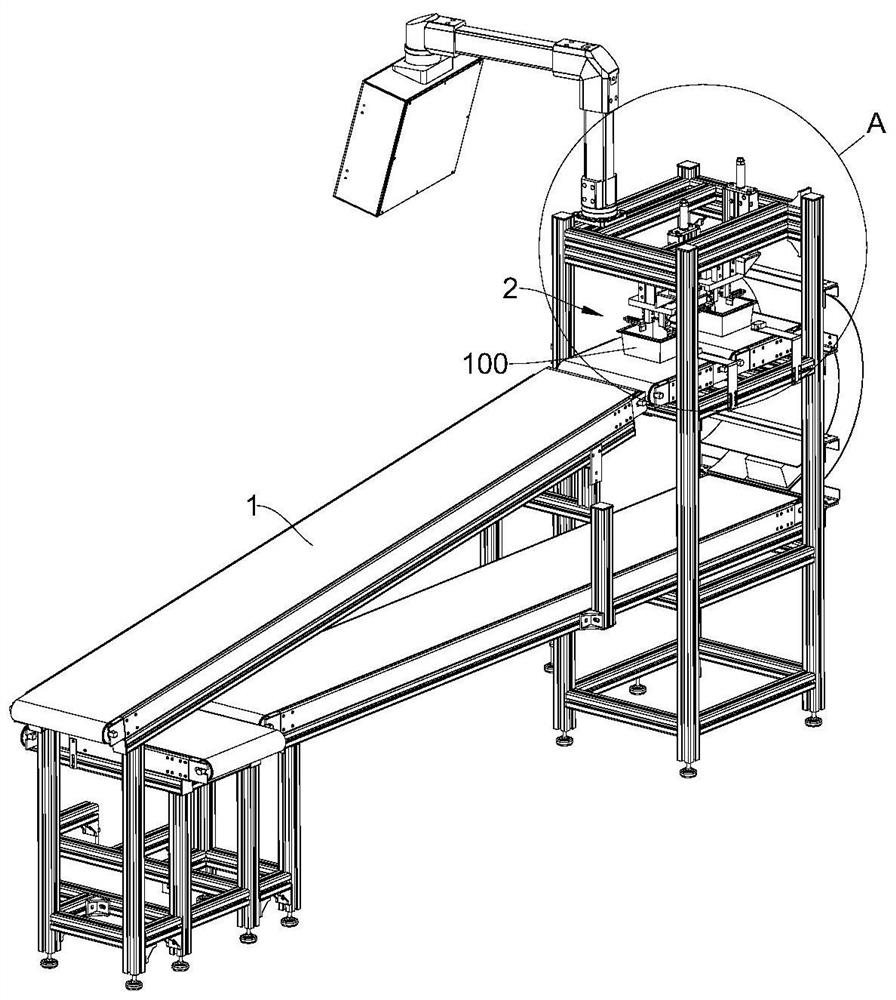

[0041] Please refer to figure 1 The present invention provides a demoulding machine for automatically separating the box body 100 of the boxed material and the solidified material in the box body 100. The solidified material in this embodiment is frozen hot pot bottom material. The demoulding machine includes a first conveying mechanism 1 , a separating mechanism 2 , an overturning mechanism 3 , a second conveying mechanism 4 , a pushing mechanism 5 and a demoulding mechanism 6 arranged sequentially along the conveying direction of boxed materials.

[0042] Wherein, the first conveying mechanism 1 may be but not limited to adopt a conventional belt conveyor, and the first conveying mechanism 1 is used to convey the boxed materials with the opening upward to the separation mechanism 2 for separation.

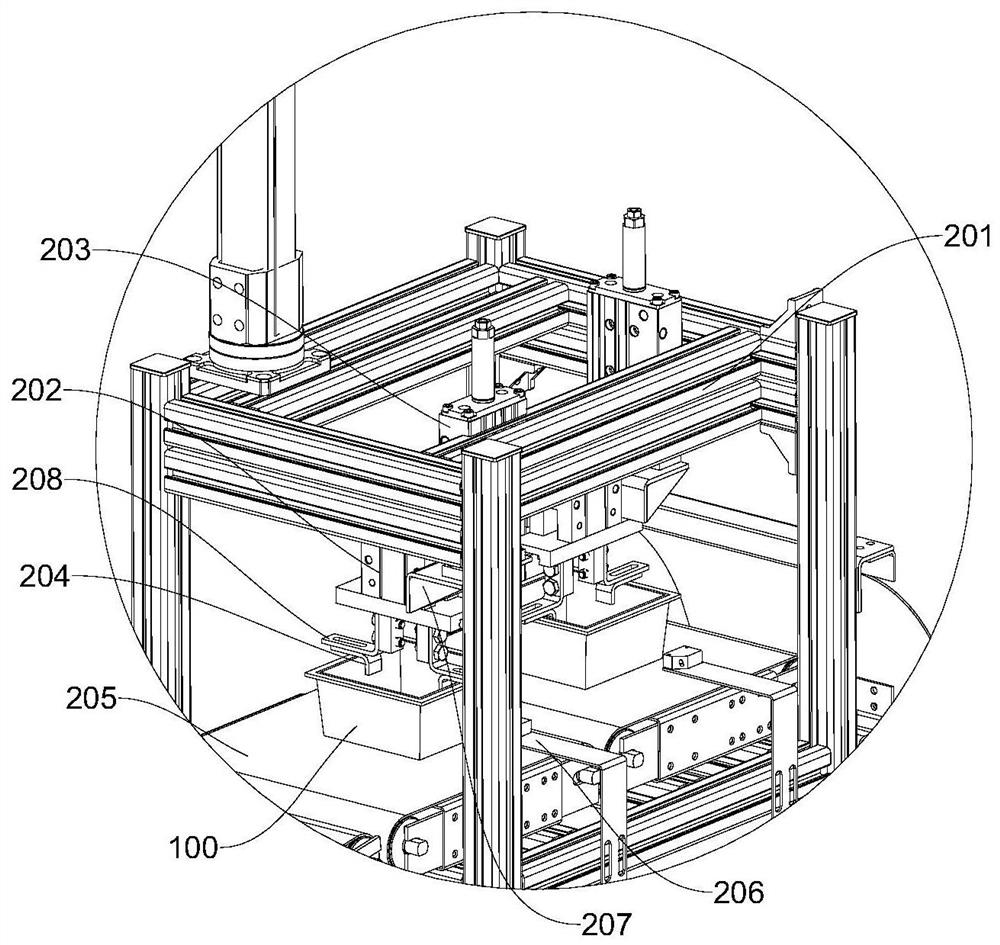

[0043] The separation mechanism 2 is used to separate the inner wall of the box body 100 from the outer wall of the solidified material, and transport the separated boxed materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com