Engine timing system and engine timing control method

A timing control and timing system technology, applied in engine control, engine components, combustion engines, etc., can solve problems such as engine performance degradation, long time, easy wear and deformation of timing chains, etc., to avoid performance degradation and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] When operating in the engine, the engine cylinder has been intuitive, compressed, done, and exhaust four strokes to complete the fuel combustion process. In order to ensure that the cylinder can be normally inhaled and intake, the engine timing system is required to open or close the engine's intake valve and exhaust valve.

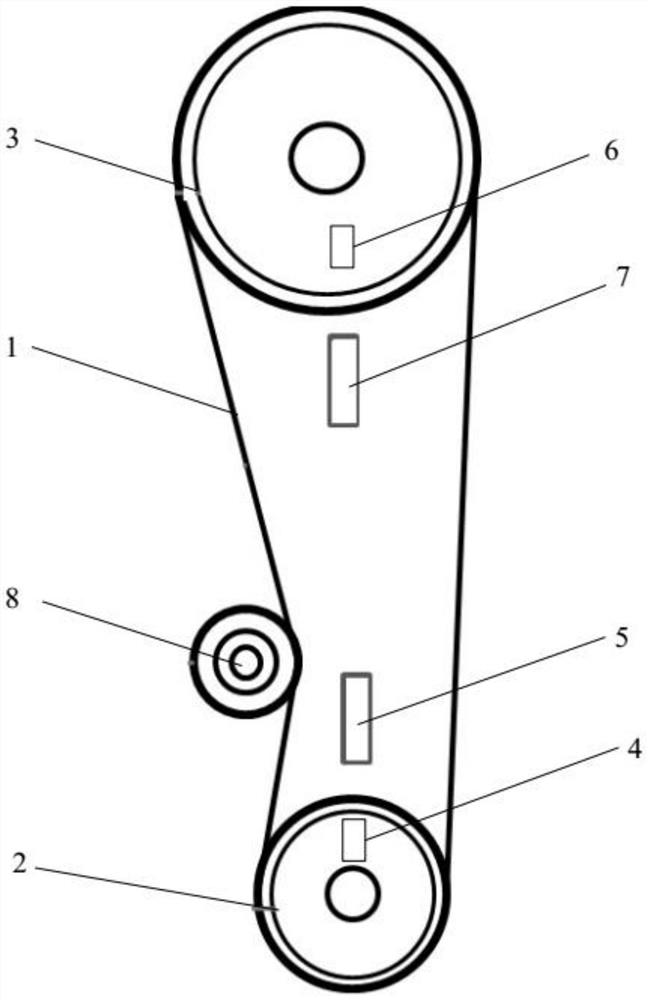

[0048] like figure 1 As shown, this embodiment provides an engine timing system, the engine timing system includes timing transmission belt 1, the crankshaft drive wheel 2, and the cam shaft drive wheel 3, the crankshaft drive wheel 2 is set on the crankshaft and fixedly connected to it. The camshaft drive wheel 3 is disposed on the camshaft and fixed thereof, and the timing transmission belt 1 is respectively wound around the crankshaft drive wheel 2 and the cam shaft transmission. As the crankshaft rotation, the rotation of the crankshaft drive wheel 2 is rotated, and the movement of the transmission belt 1 and the rotation of the cam shaft transmiss...

Embodiment 2

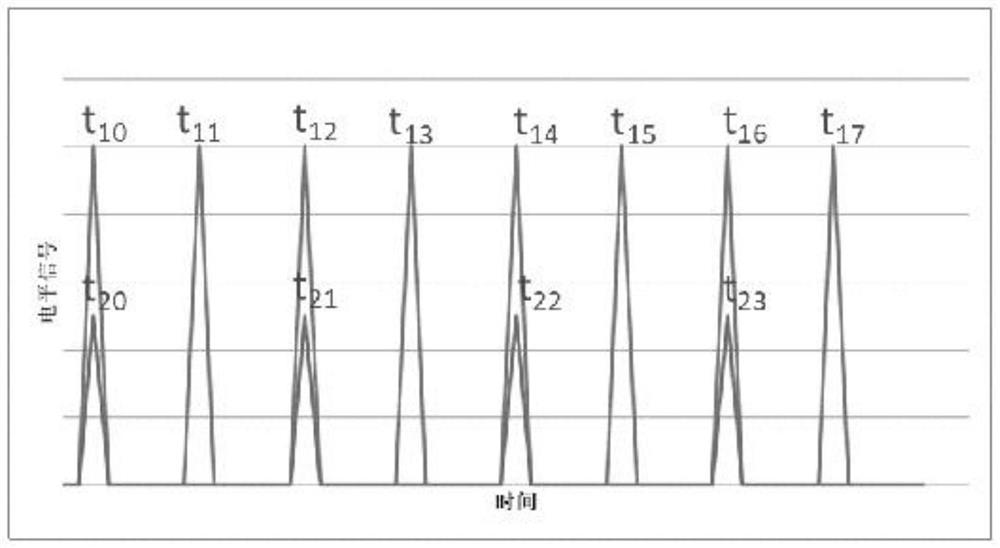

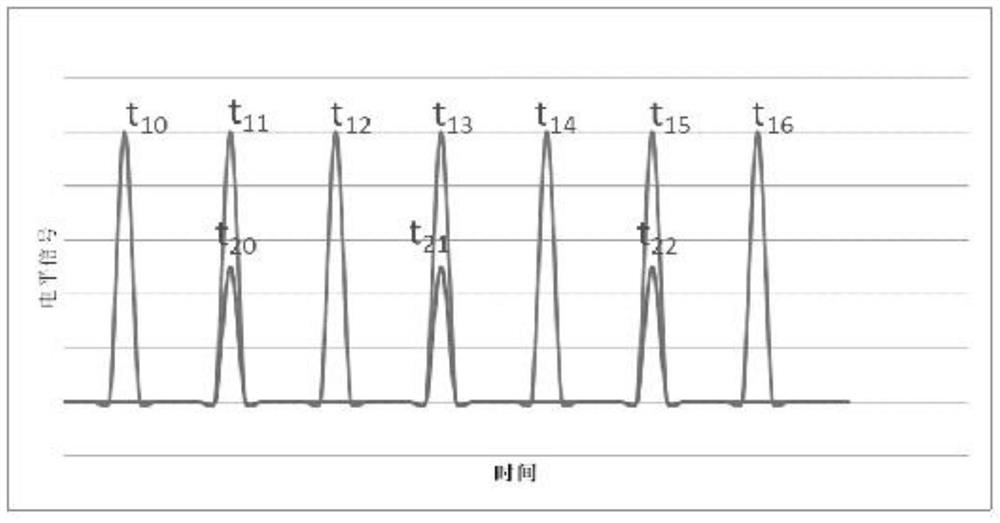

[0058] Since the sensor will issue a low level because the magnetic block is gradually rotated away from the sensor corresponding to the sensor thereof. When the magnetic block is gradually rotated in a direction adjacent to the sensor corresponding to the sensor, the sensor is high, but when the sensor can initially identify the magnetic block, the distance between the sensor and the magnetic block is relatively far, then high electricity The flat signal is relatively low; as the gear is rotated, the distance between the sensor and the magnetic block gradually decreases, and the high level signal gradually increases; when the relative position between the sensor and the magnetic block, the high level signal reaches the highest value. As the gear continues to rotate, the distance between the sensor and the magnetic block is gradually increased, and the high level signal gradually decreases. Therefore, the high level signal is specifically similar to a parabola similar to the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com