Blade zero drift detection method and system, electronic device and storage medium

A zero-position drift and detection method technology, applied in measurement devices, wind power generation, instruments, etc., can solve the problems of large error and high detection cost of fan blades, and achieve the effect of avoiding additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

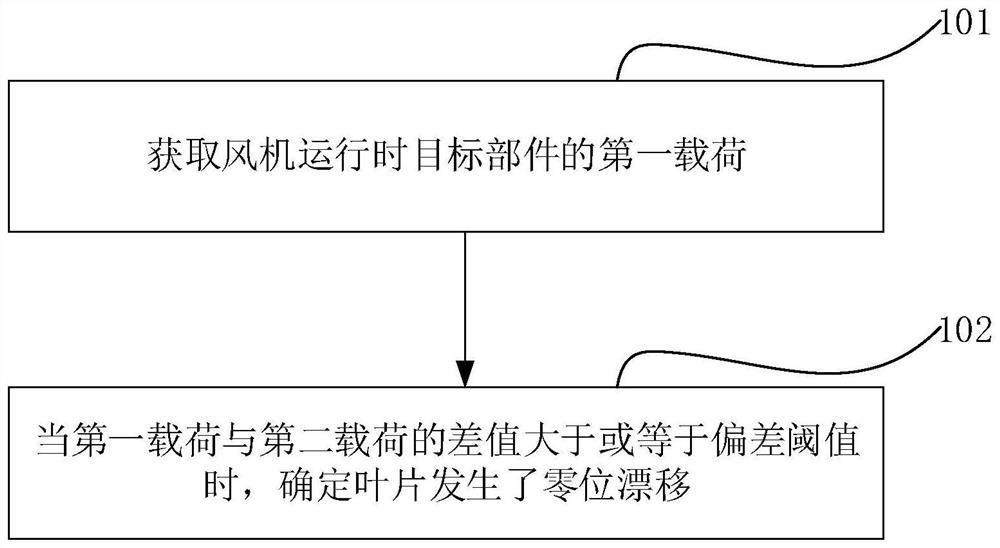

[0054] This embodiment provides a detection method for blade zero drift, such as figure 1 As shown, the detection method includes:

[0055] Step 101. Obtain the first load of the target component when the wind turbine is running.

[0056] Step 102, when the difference between the first load and the second load is greater than or equal to the deviation threshold, it is determined that the blade has zero drift.

[0057] Wherein, the second load is the load of the target component obtained when the fan is running after zeroing the blades of the fan.

[0058] Wherein, the target component includes at least one of the main shaft, the hub, the wind wheel and the blade, and the first load of the target component can be measured in various ways, such as the first load of the target component can be obtained by a load strain sensor, or can be measured by The distance or vibration sensor measures the displacement or deformation of the target part and calculates the first load based on...

Embodiment 2

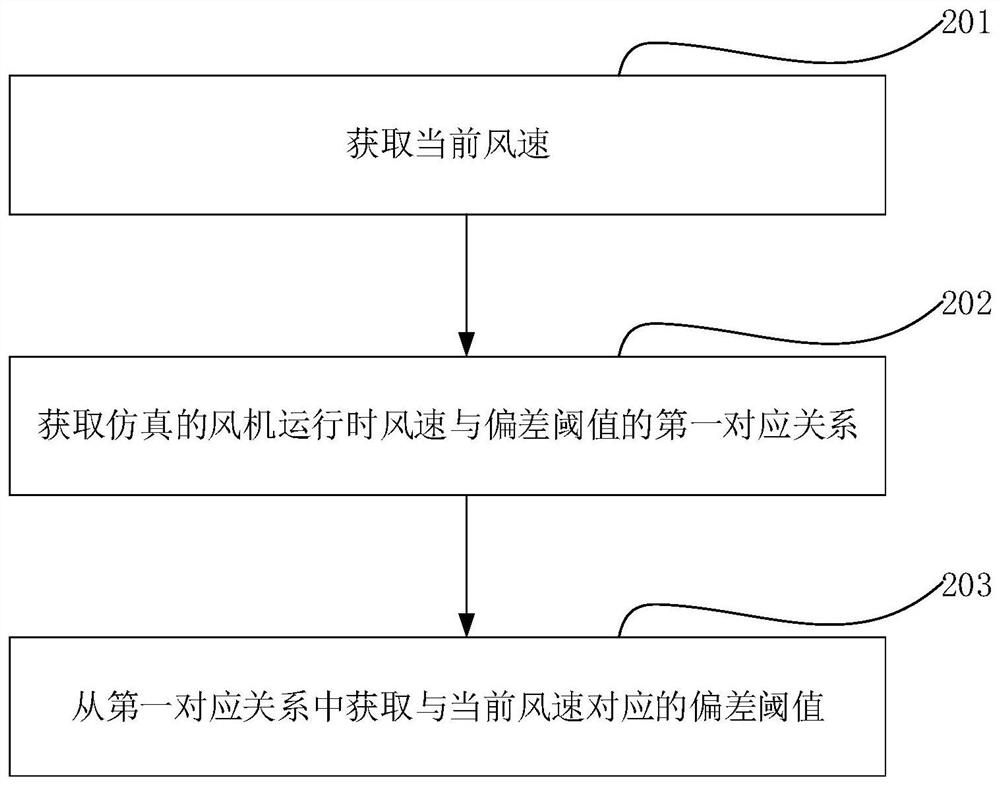

[0064] This embodiment provides a detection method for blade zero drift, and this embodiment is based on Embodiment 1, such as figure 2 As shown, the detection method further includes:

[0065] Step 201, acquiring the current wind speed.

[0066] Step 202, obtaining a first corresponding relationship between the simulated fan speed and the deviation threshold during operation.

[0067] Among them, the deviation threshold represents the deviation load of the target component of the fan when zero drift occurs and when zero drift does not occur;

[0068] Step 203. Obtain a deviation threshold corresponding to the current wind speed from the first correspondence.

[0069] The deviation threshold compared in step 102 is the deviation threshold corresponding to the wind speed acquired in step 203 .

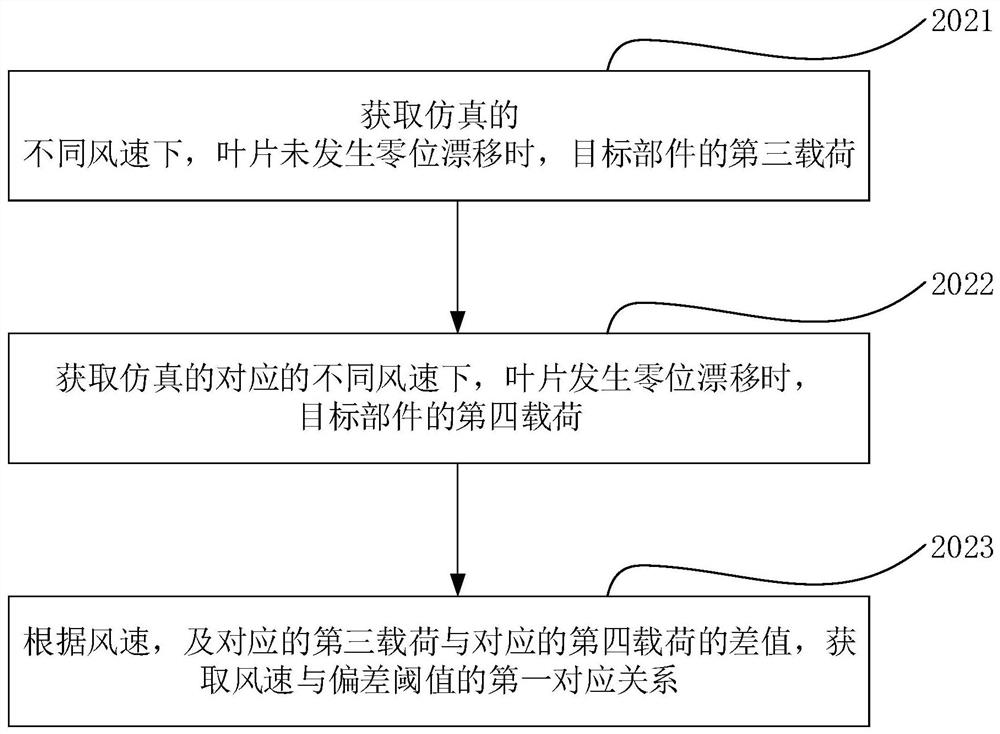

[0070] In this example, if image 3 As shown, step 202 specifically includes:

[0071] Step 2021, obtaining the third load of the target component when the blade does not drift at...

Embodiment 3

[0093] This embodiment provides a detection system for blade zero drift, such as Image 6 As shown, the detection system includes: a load acquisition module 301 and a blade detection module 302, the load acquisition module 301 is used to obtain the first load of the target component when the fan is running, and the blade detection module 302 is used to compare the first load with the second load When the difference is greater than or equal to the deviation threshold, it is determined that the blade has zero drift, and the second load is the load of the target component obtained when the fan is running after zeroing the blade of the fan .

[0094] Wherein, the target component includes at least one of the main shaft, the hub, the wind wheel and the blade, and the first load of the target component can be measured in various ways, such as the first load of the target component can be obtained by a load strain sensor, or can be measured by The distance or vibration sensor measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com