Quick-heating central air conditioner water circulation control system and method

A central air-conditioning and control system technology, applied in heating and ventilation control systems, control input related to air characteristics, space heating and ventilation control input, etc., can solve the problems of increased energy consumption, long time, etc., to improve indoor temperature , Improve the overall energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

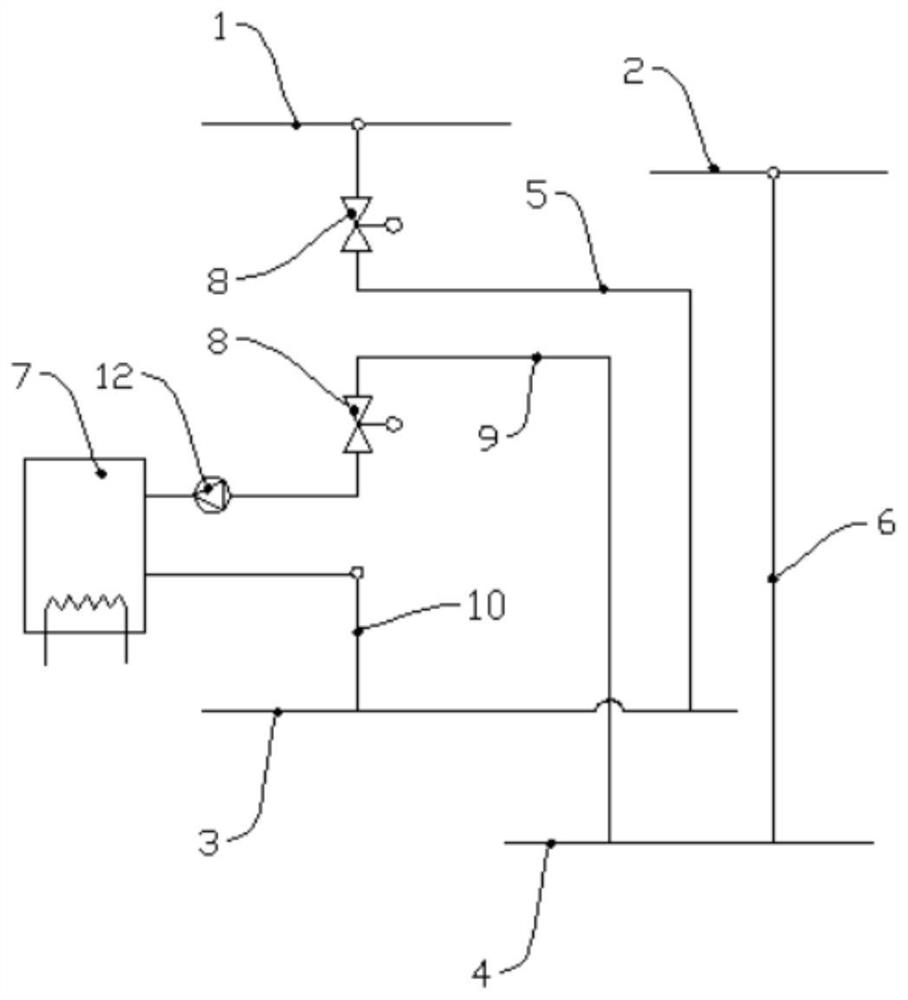

[0059] A water cycle control system for central air-conditioning with rapid temperature rise, which is connected to the dry water supply pipe 1 and the dry return pipe 2 of the central air-conditioning control system, and the indoor water supply pipe 3 and the indoor return water pipe 4 on the user side, wherein the indoor water supply pipe 3 and the indoor water return pipe 4 The indoor return water pipes 4 are respectively connected to the indoor fan coils; including: the first water circulation system, realizing the water circulation between the dry water supply pipe 1, the indoor water supply pipe 3, the indoor fan coil, the indoor return water pipe 4 and the dry return water pipe 2; The second water circulation system is provided with an electric hot water tank 7, and realizes water circulation between the indoor water supply pipe 3, the indoor fan coil unit, the indoor water return pipe 4 and the electric hot water tank 7.

[0060] As far as the installation method is con...

Embodiment 2

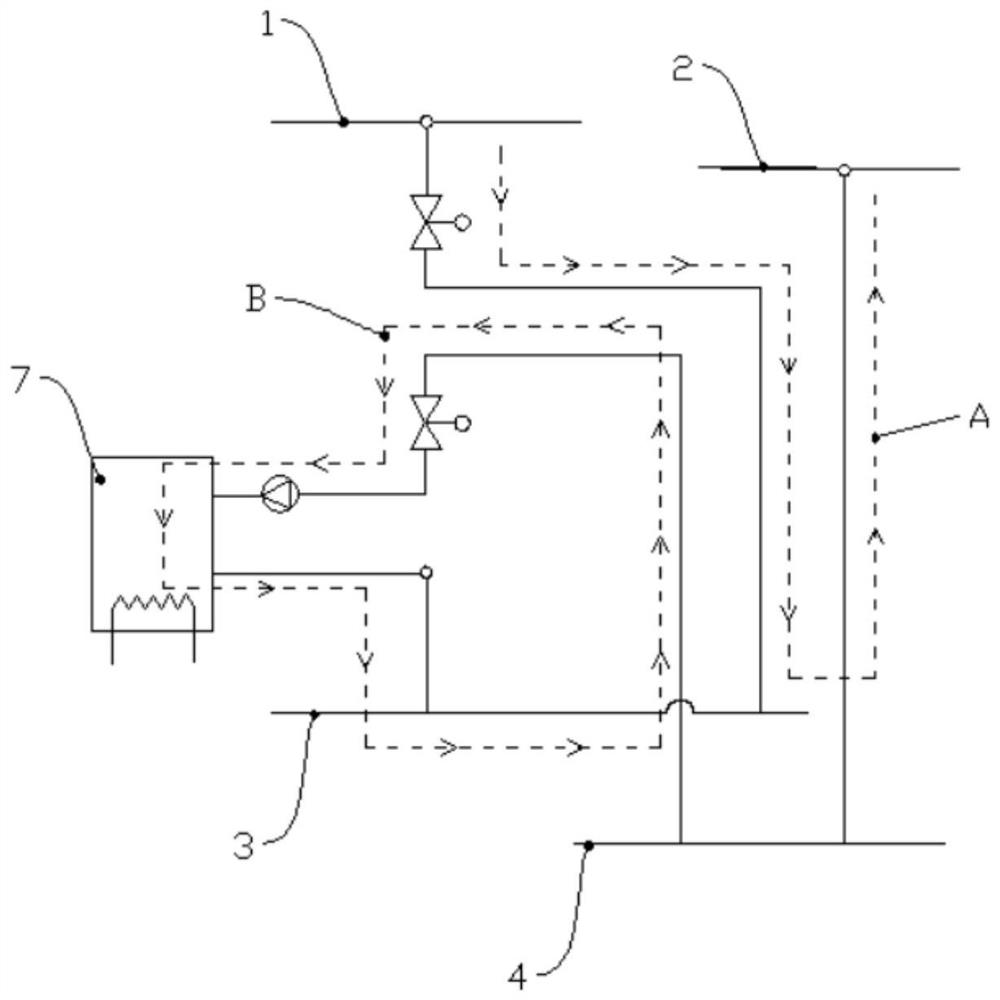

[0063] In this example, if Figure 1~3 As shown, on the basis of Embodiment 1, a specific pipeline connection method of a central air-conditioning water circulation control system with rapid temperature rise is provided:

[0064] The first water circulation system includes: a first pipeline 5, connecting the dry water supply pipe 1 and the indoor water supply pipe 3; a second pipeline 6, connecting the dry return pipe 2 and the indoor return water pipe 4; the first pipeline 5 is provided with an electric control The two-way valve 8, the water supply flows from the dry water supply pipe 1 to the indoor water supply pipe 3.

[0065] The first water circulation system in this embodiment can use the pipeline form of the existing system. At present, the above-mentioned pipeline form is used to supply hot water to the indoor fan coil unit, so no additional construction is required. The indoor water supply pipe 3 and the indoor water return pipe 4 are branch structures corresponding...

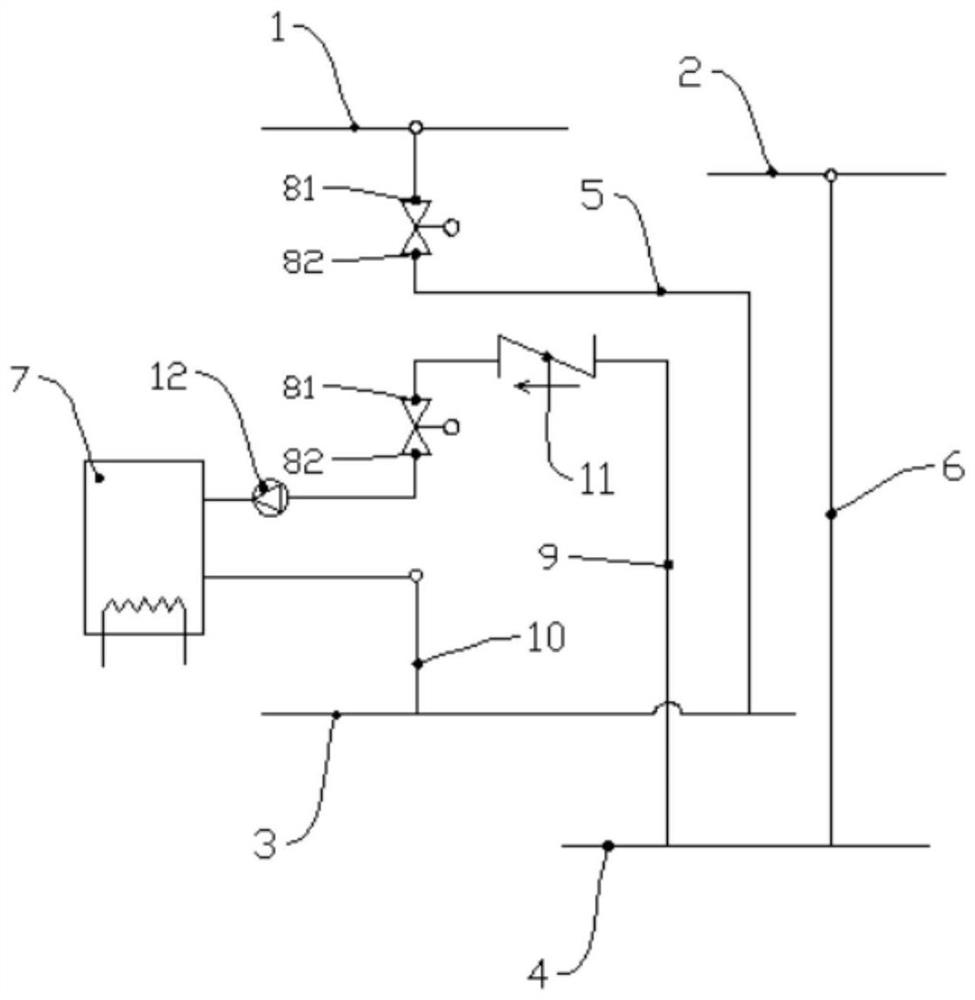

Embodiment 3

[0073] In this embodiment, on the basis of Embodiment 1, as Figure 4~6 As shown, with respect to embodiment two, another specific pipeline connection method of the central air-conditioning water circulation control system with rapid temperature rise is provided:

[0074] The first water circulation system includes: a first pipeline 5, connecting the dry water supply pipe 1 and the indoor water supply pipe 3; a second pipeline 6, connecting the dry return water pipe 2 and the indoor return water pipe 4; see Figure 5 , the second water circulation system includes: connecting pipeline 13, connecting the first pipeline 5 and the second pipeline 6, the first connecting point 51 of the connecting pipeline 13 and the first pipeline 5 divides the first pipeline 5 into and The first section 52 connected to the dry water supply pipe 1, and the second section 53 connected to the indoor water supply pipe 3, the first section 52 is provided with an electronically controlled two-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com