Efficient 1-Wire temperature sensor testing tool

A technology of temperature sensor and test tool, applied in the field of temperature sensor, can solve problems such as low work efficiency, achieve the effect of high work efficiency and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

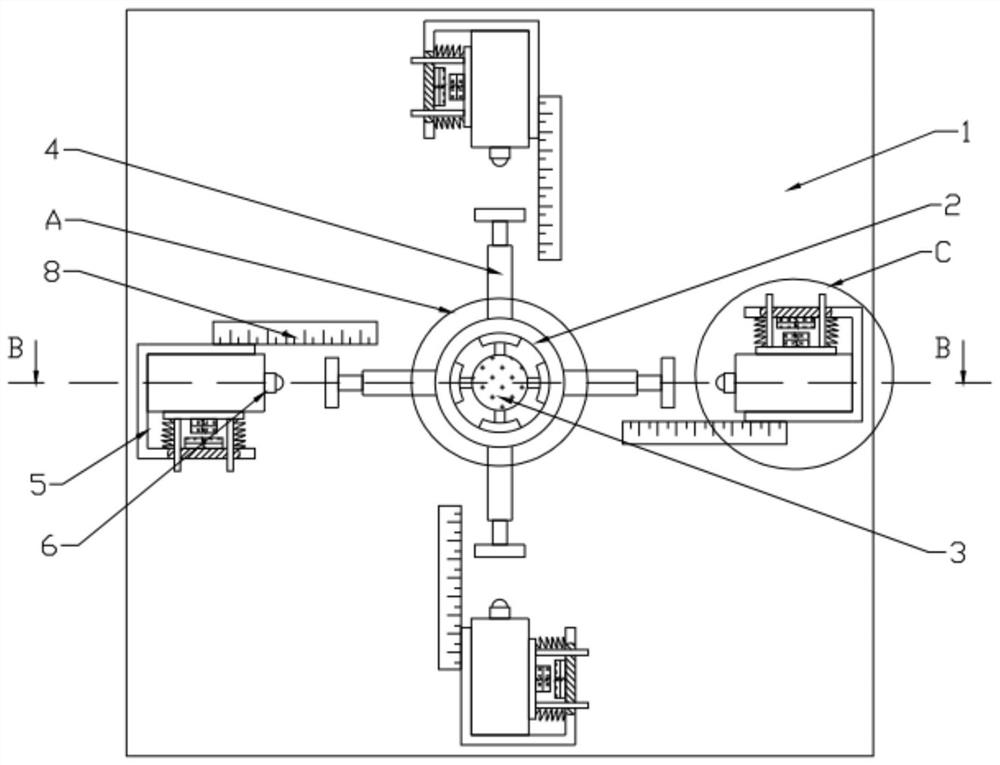

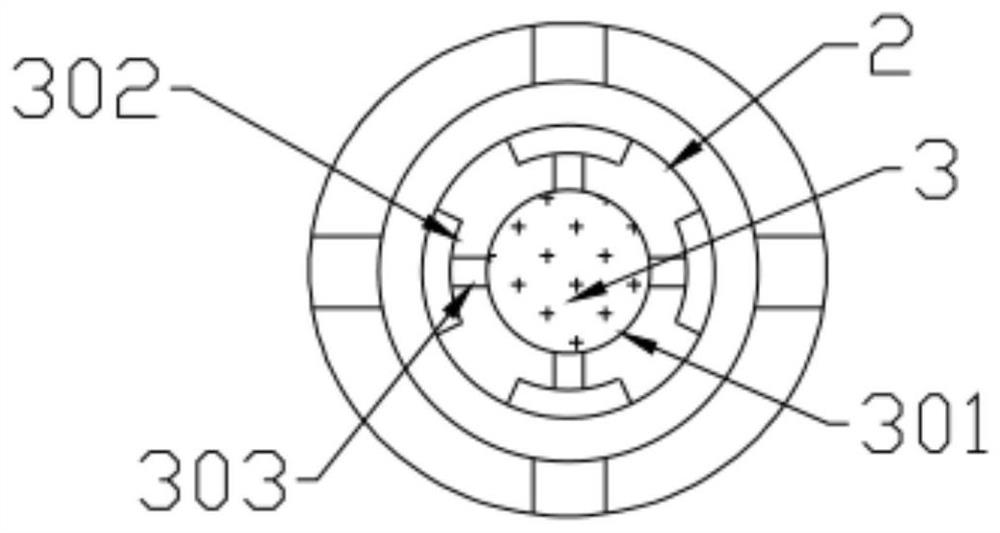

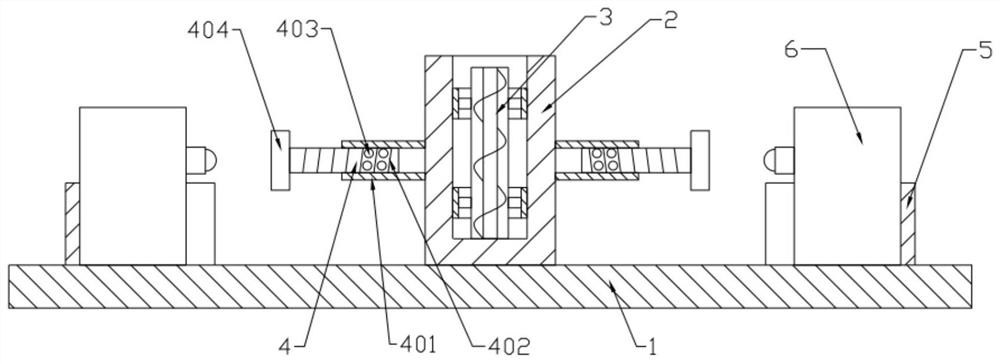

[0022] see Figure 1~4 , in the embodiment of the present invention, a high-efficiency 1-Wire temperature sensor testing tool, including a workbench 1, a heat conducting ring 2 is installed in the middle of the workbench 1, and a heating device 3 is installed in the heat conducting ring 2, The heating device 3 includes: a heating cell 301, a heat dissipation plate 302 and a heat conducting rod 303, the heating cell 301 is installed inside the heat conducting ring 2, and a plurality of heat conducting rods 303 are evenly distributed on the outside of the heating cell 301 , the end of each of the heat conducting rods 303 is equipped with a heat dissipation plate 302 that fits the heat conduction ring 2, the appearance of the heat dissipation plate 302 is arc-shaped, and the outer ring of the heat conduction ring 2 is evenly distributed with four A heat conduction device 4, the heat conduction device 4 includes: a threaded sleeve 401, a threaded rod 402, a ball 403 and a disc 404...

Embodiment 2

[0024] see Figure 1~4 , In the embodiment of the present invention, the heat dissipation plate 302, the heat conducting rod 303, the threaded sleeve 401, the threaded rod 402 and the disc 404 are all made of copper, so that they have good thermal conductivity.

[0025] The working principle of the present invention is: when the efficient 1-Wire temperature sensor testing tool is used, a plurality of temperature sensor bodies 6 can be respectively installed in the installation frame 5, the electromagnet 702 is opened, and the electromagnet 702 and the permanent magnet 703 The repulsive force between drives the electromagnet 702 and the splint 701 to move, and the temperature sensor body 6 is clamped by the splint 701. Then, the heat is generated by the heating device 3, and the heat is transferred to the heat conduction device 4 through the heat conduction ring 2. The body 6 measures the temperature on the heat conduction device 4, which is conducive to testing multiple temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com