Microscopic optical system for arc circumference defect detection

A defect detection and optical system technology, applied in the field of micro-optical systems, can solve problems such as effect and efficiency discount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] On the basis of the above structure, this embodiment also includes a platform on which the drive unit is fixedly installed.

[0044]The above-mentioned driving unit can be a motor, which is fixedly installed on the platform through bolts, and its driving end is vertically upward, and is fixedly connected with the center of the lower surface of the horizontally arranged rotating disk. During detection, the product 4 is directly placed on the rotating disk, and the motor drives the rotating disk and the product 4 to rotate, so that the product 4 makes a circular motion, so that the infinite imaging unit can fully capture the image of the product 4.

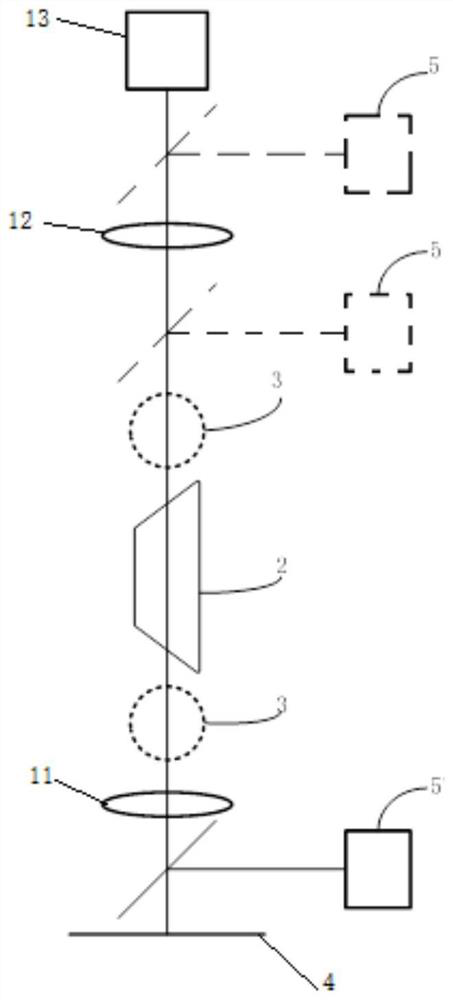

[0045] In addition to the implementation mode, during the detection process, the product 4 to be detected can also be directly placed on the platform, and it is stationary relative to the platform; at this time, the drive unit is fixed and erected on the platform through a bracket, and is used to drive the imaging rotation uni...

Embodiment 2

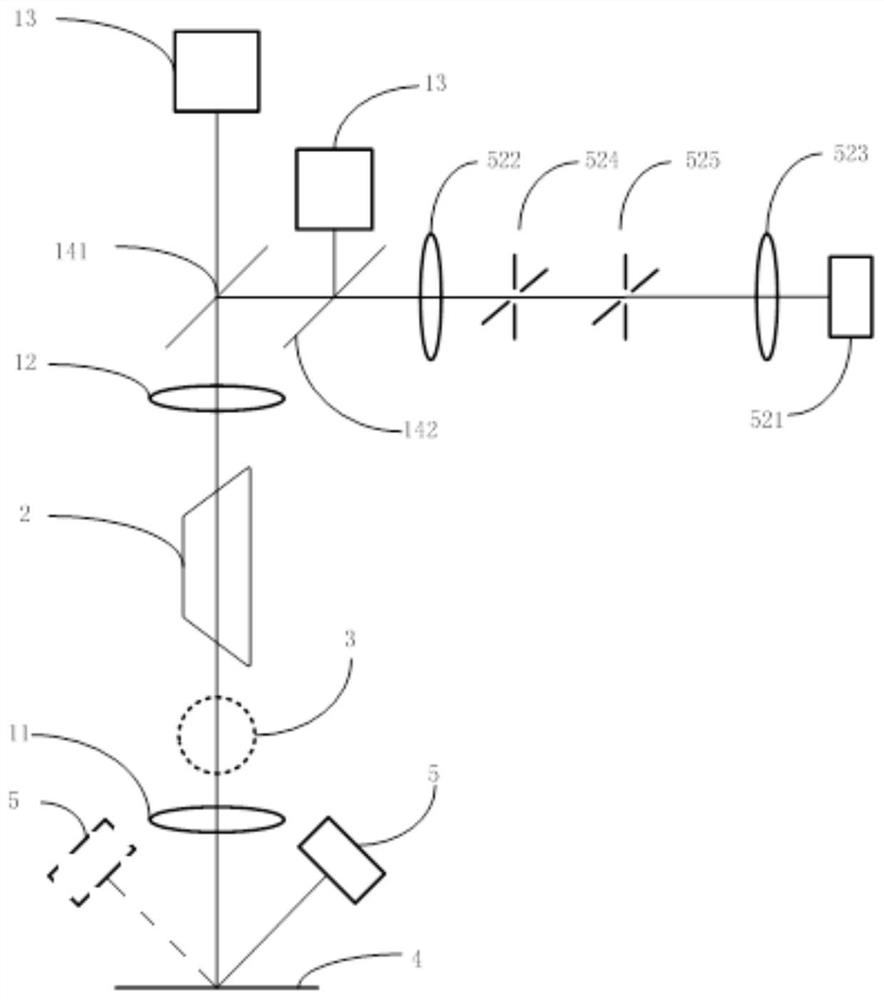

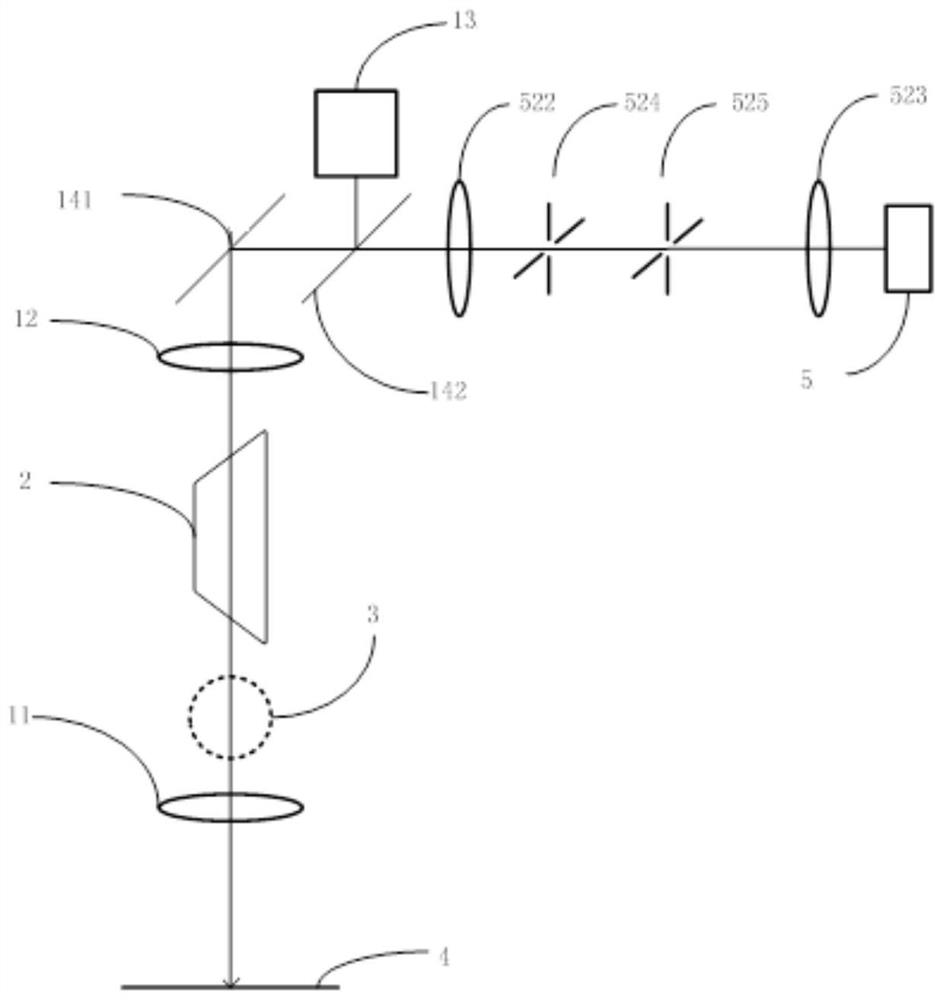

[0049] On the basis of the above structure, in this embodiment, the infinity imaging unit includes an infinity microscopic objective lens 11 and an imaging device, and the infinity microscopic objective lens 11 and the imaging device are erected above the drive unit at intervals from bottom to top. The micro-objective lens 11 is used to form the light generated by the product 4 into parallel light, which is then imaged by the imaging device; the imaging rotation unit is located between the infinity micro-objective lens 11 and the imaging device. During the detection process, the light generated by the product 4 passes through the infinity microscope objective lens 11 to form parallel light, and then is imaged by the imaging device. The imaging effect is better, so as to improve the effect of product 4 defect detection.

[0050] During detection, the above-mentioned imaging device is fixedly set, and the infinity microscopic objective lens 11 can be fixedly set, and this detecti...

Embodiment 3

[0052] On the basis of Embodiment 2, in this embodiment, the infinity imaging unit further includes an autofocus device 3 , which is fixed and used to drive the infinity microscope objective lens 11 to move up and down. During the detection process, the infinity microscope objective lens 11 is driven to move up and down by the autofocus device 3 to meet the imaging requirements of different products 4 and has a wider application range.

[0053] What above-mentioned autofocus device 3 adopted is the autofocus system in the prior art, and its specific structure and principle are not repeated here, and it is fixedly erected on the top of the platform by a bracket; It is fixedly installed on the autofocus system, and the position of the infinity microscopic objective 11 is adjusted up and down by the autofocus system, so as to adjust the distance between the infinity microscopic objective 11 and the imaging device, so as to meet the detection requirements of different products 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com