Backlight module

A technology of backlight module and light source, applied in the direction of light guide, optics, optical components, etc., can solve the problems of increasing the space of the light-emitting module, increasing the volume of the backlight module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

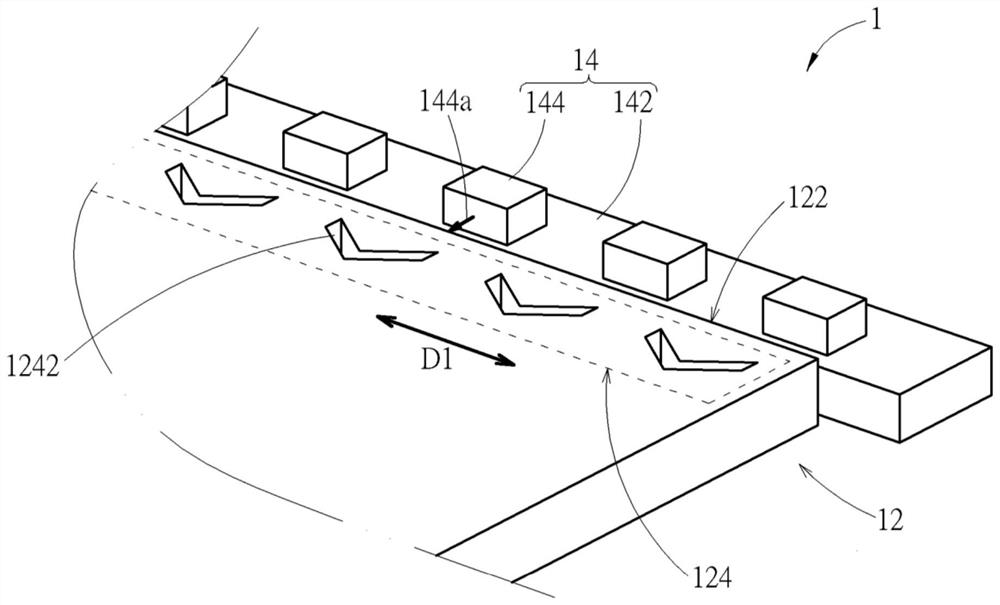

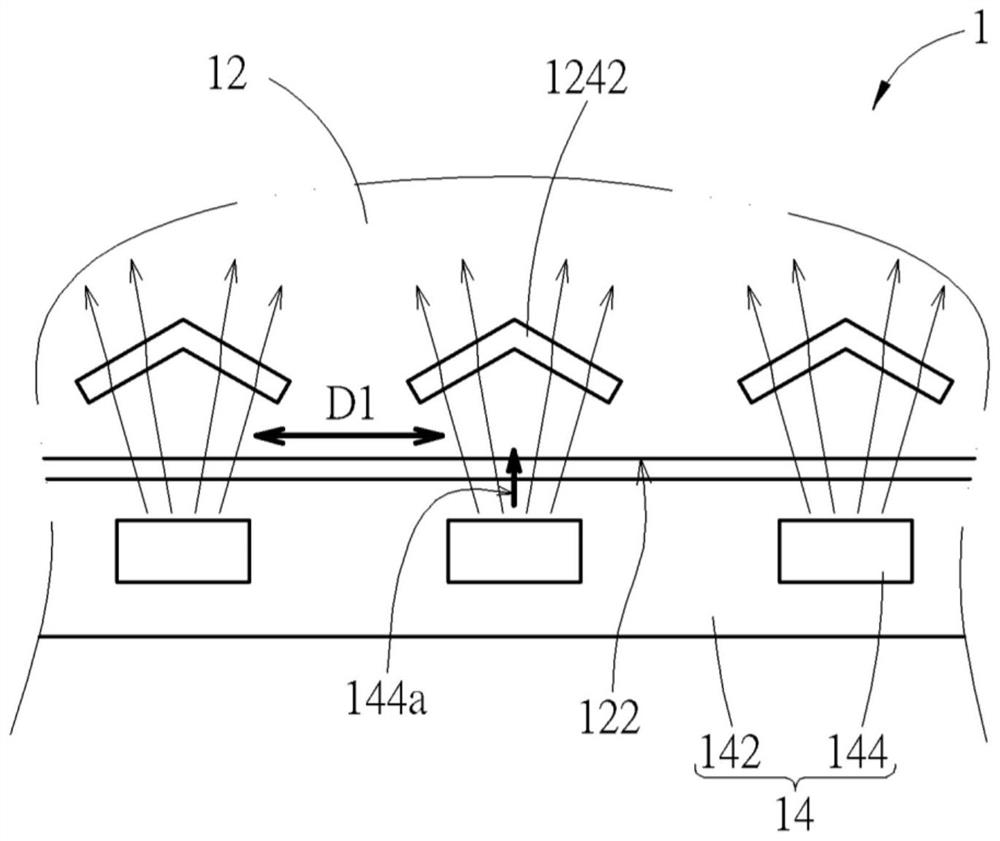

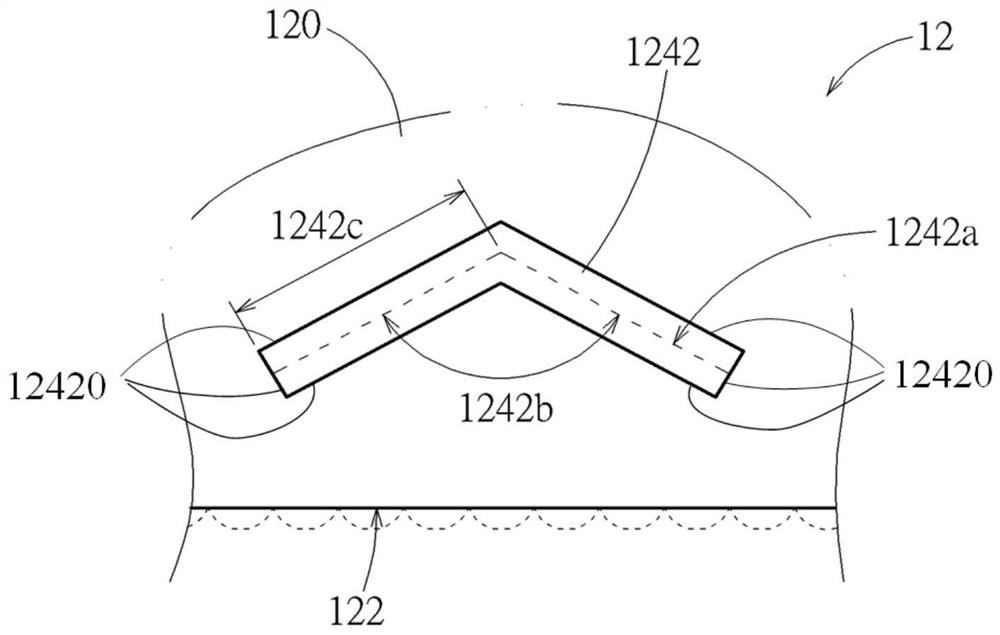

[0055] see figure 1 and figure 2 . The backlight module 1 according to an embodiment includes a light guide structure 12 and a light source device 14 . The light guide structure 12 is formed by the material of the first optical medium (such as but not limited to a light-transmissible polymer material, such as by injection molding) and the light guide structure 12 has a light incident surface 122 and a light diffusion structure 124 (the range of which is within The dotted line box is shown in the figure), the light diffusion structure 124 is located inside the light guide structure 12 and includes a plurality of hollow structures 1242 . When the backlight module 1 is applied to a keyboard, the extending direction of the light incident surface 122 generally correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com