Solid-liquid classification treatment device for metal cutting fluid recycling

A technology of metal cutting fluid and processing device, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of inability to separate the three for processing, and inability to recover cutting fluid, and achieve the effect of saving cutting fluid use and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

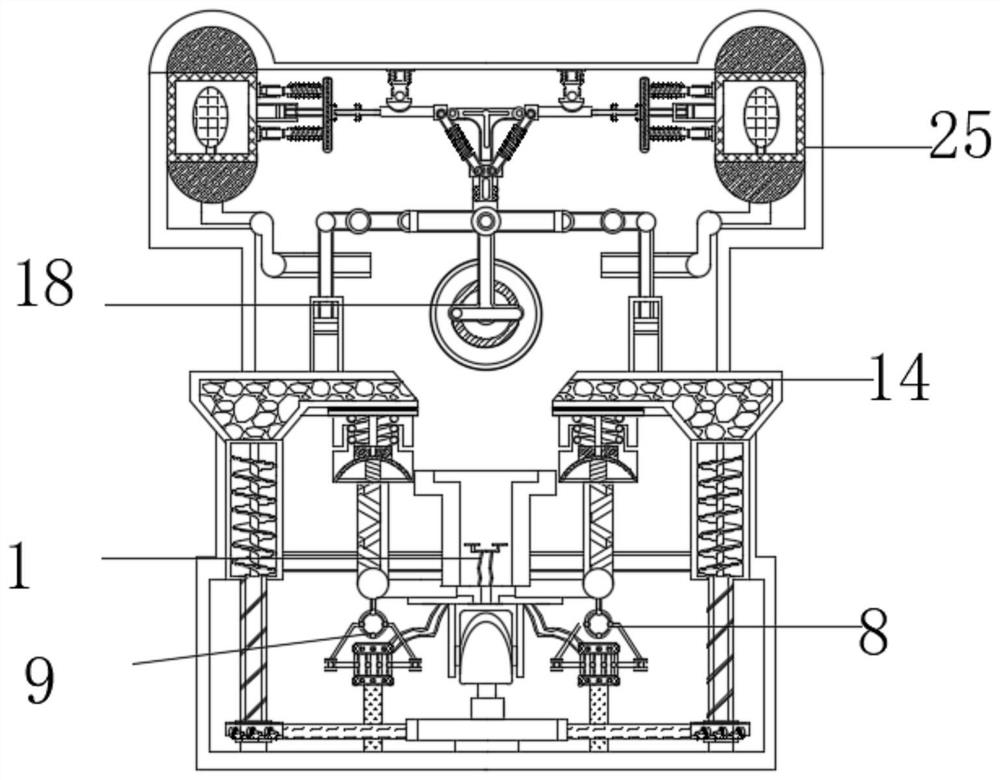

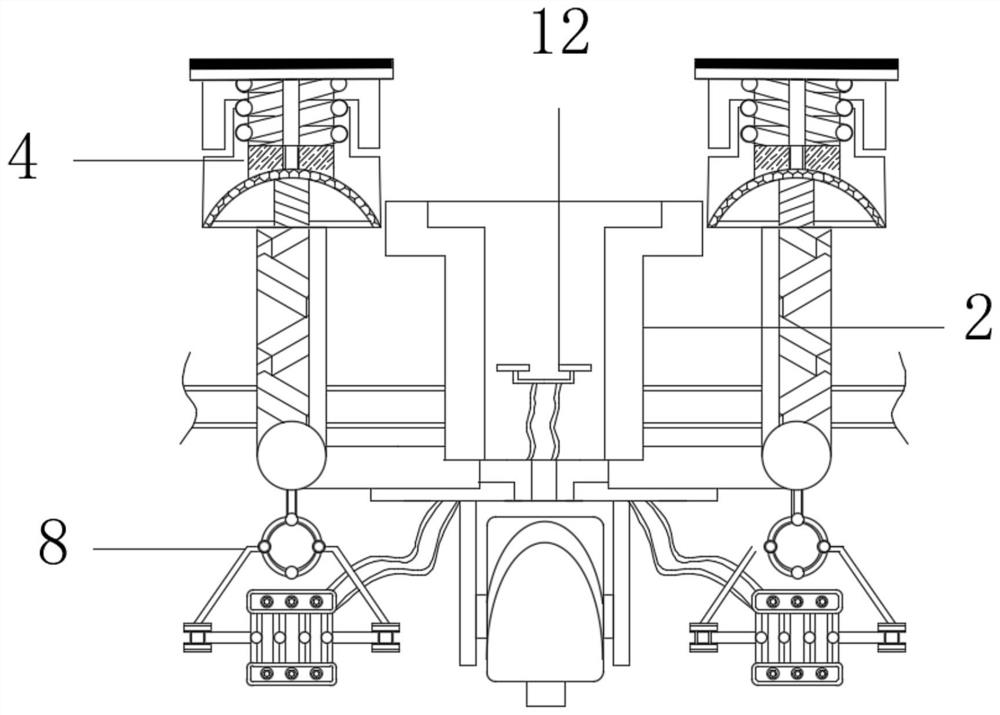

[0028] see figure 1 and 5 , a solid-liquid classification treatment device for metal cutting fluid recovery, including a static mechanism 1 and an oil suction mechanism 8, the static mechanism 1 includes a layered tank 2, and the left and right sides of the layered tank 2 are slidingly connected with drains The tube 3, the surface of the layered groove 2 is fixedly connected with the extension spring rod 4, the bottom of the layered groove 2 is fixedly connected with the cap 5, the inside of the cap 5 is movably connected with the rotating block 6, and the surface of the rotating block 6 is movably connected with the chain 7 .

[0029] Further, the oil suction mechanism 8 includes a display frame 9, the bottom of the display frame 9 is movably connected with a pull block 10, the inside of the pull block 10 is fixedly connected with a suction bag 11, and the top of the suction bag 11 is fixedly connected with a hose 12, and the top of the hose 12 A buoyancy plate 13 is fixedl...

Embodiment 2

[0032] see figure 1 and 6 , a solid-liquid classification treatment device for metal cutting fluid recovery, including a static mechanism 1 and an oil suction mechanism 8, the static mechanism 1 includes a layered tank 2, and the left and right sides of the layered tank 2 are slidingly connected with drains The tube 3, the surface of the layered groove 2 is fixedly connected with the extension spring rod 4, the bottom of the layered groove 2 is fixedly connected with the cap 5, the inside of the cap 5 is movably connected with the rotating block 6, and the surface of the rotating block 6 is movably connected with the chain 7 .

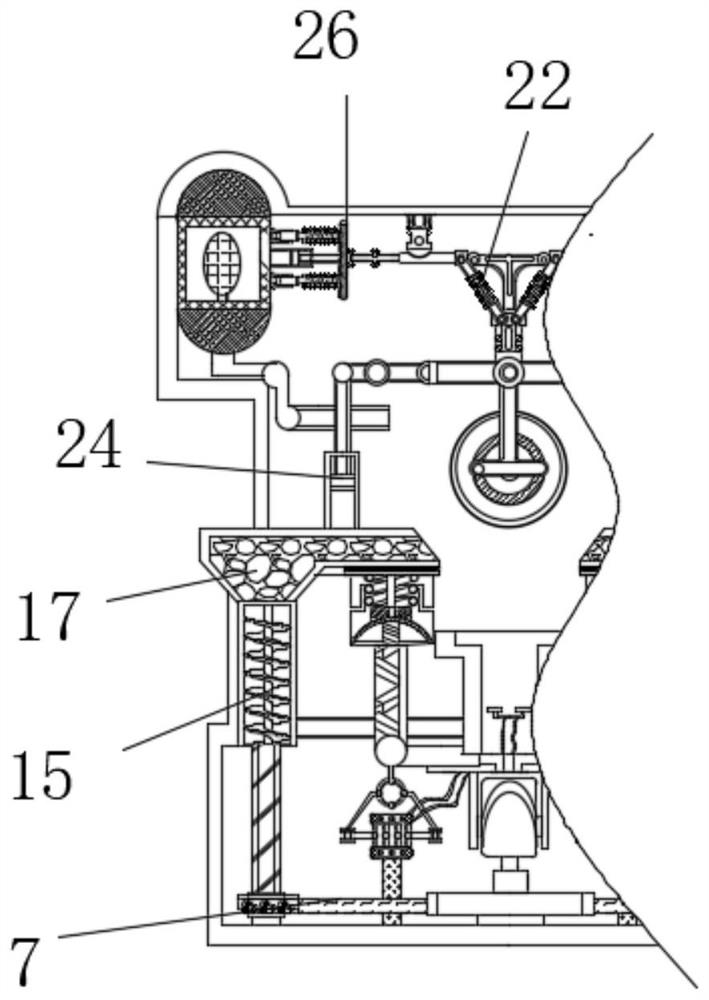

[0033] Further, the time difference mechanism 18 includes a cutting rotary knife 19, the front of the cutting rotary knife 19 is movably connected with a linkage rod 20, the surface of the linkage lever 20 is movably connected with a flat mouth plate 21, and the top of the flat mouth plate 21 is fixedly connected with a spring bar 22, and the spring ...

Embodiment 3

[0036] see Figure 1-8, a solid-liquid classification treatment device for metal cutting fluid recovery, including a static mechanism 1 and an oil suction mechanism 8, the static mechanism 1 includes a layered tank 2, the left and right sides of the layered tank 2 are slidingly connected with The drain pipe 3, the surface of the layered groove 2 is fixedly connected with the spring rod 4, the bottom of the layered groove 2 is fixedly connected with the cap 5, the inside of the cap 5 is movably connected with the rotating block 6, and the surface of the rotating block 6 is movably connected with The chain 7, the bottom of the stationary mechanism 1 is fixedly connected with the oil suction mechanism 8, the oil suction mechanism 8 includes a display frame 9, the bottom of the display frame 9 is movably connected with a pull block 10, the inside of the pull block 10 is fixedly connected with a suction bag 11, and the suction bag 11 The top is fixedly connected with a hose 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com