Device and method for multi-working-condition operation of C9 removing tower of pyrolysis gasoline hydrogenation device

A technology of decarbonization nine-tower and hydrogenation unit, which is applied in the field of pyrolysis gasoline hydrogenation, and can solve the problems of short maintenance period and shutdown maintenance of styrene extraction unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] This example is used to illustrate the device and method for the decarburization nine-tower multi-working condition operation of the pyrolysis gasoline hydrogenation device of the present invention.

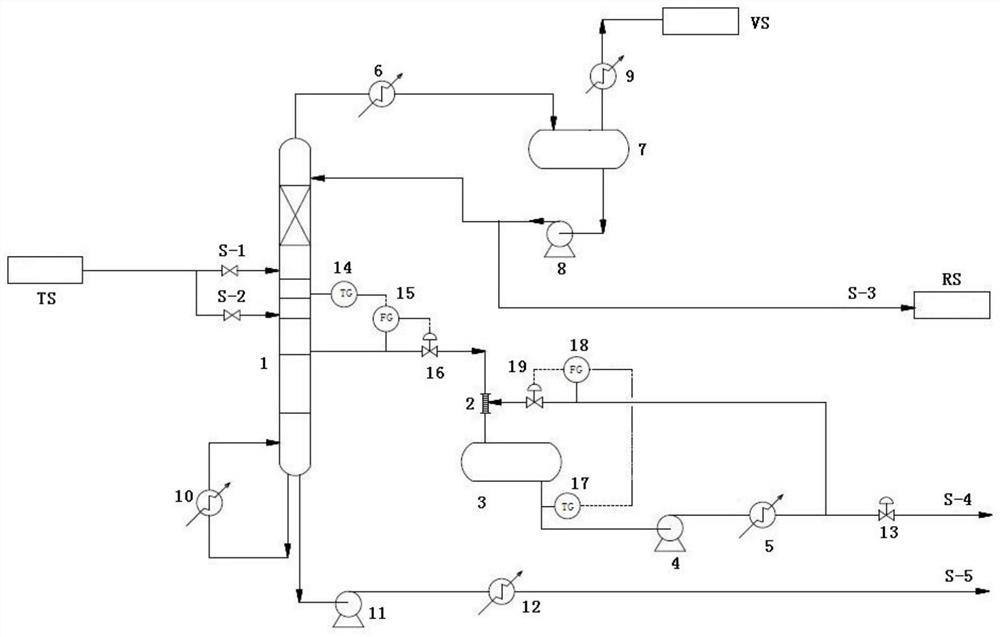

[0055] Such as figure 1 As shown, the present invention provides a kind of device of decarburization nine-tower multi-working mode operation of pyrolysis gasoline hydrogenation unit, and this device comprises decarburization nine-tower 1, and the middle part of described decarburization nine-tower 1 is provided with the first feed inlet and A second feed port, the first feed port is located above the second feed port;

[0056] The tower top of the decarburization nine tower 1 is provided with a tower top extraction pipeline connected to the hydrogenation reaction system RS, and along the flow direction of the material, a tower top condenser 6, a reflux tank 7 and The tower top pump 8, the reflux tank 7 is connected to the vacuum system VS through the decarburization nine ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap