Method for producing high efficiency energy saving fan vane using fin structure section bar

A technology for fan impellers and fan blades, which is applied in the field of manufacturing fan impellers by using airfoil structural profiles, can solve the problems affecting fan performance, low production efficiency and precision, and differences in prototype performance, and achieves the effect of ensuring control stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

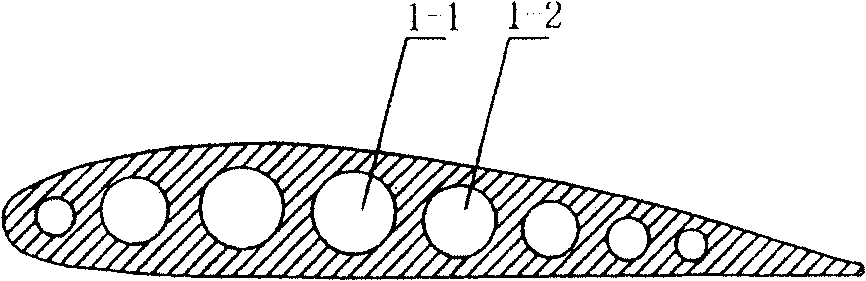

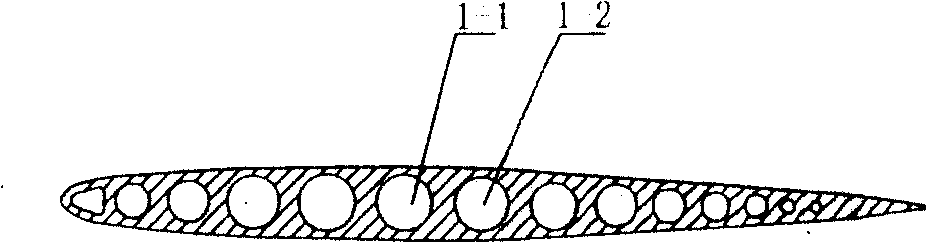

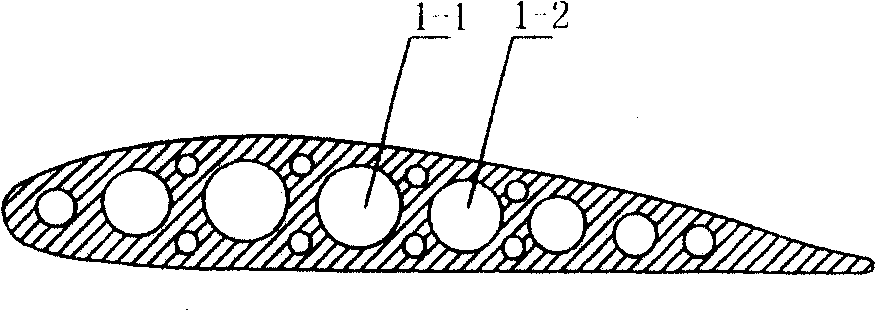

[0060] Example 1: Blade profile

[0061] The blade profile used in the present invention has been published in the patent document submitted by the applicant (patent number: 200420052872.4; invention name: hollow airfoil fan blade profile with central shaft hole).

[0062] The typical cross-sectional design structure of its profiles can be divided into the following categories:

[0063] 1. The cross-sectional structure of the formed blade that does not need to be filled when twisting, as shown in Figures 1, 2, 5, and 6;

[0064] 2. The cross-sectional structure of the formed blade that must be filled during twisting, as shown in Figures 3 and 4;

[0065] 3. The cross-sectional structure of blades that can be modified, as shown in Figures 5 and 6;

[0066] 4. Combined plug-in structure airfoil section structure, as shown in Figure 7.

Embodiment 2

[0067] Embodiment 2: the manufacture of the fan impeller that does not need to be filled when the blade is twisted (the blade section structure is shown in accompanying drawings 1, 2, 5, and 6)

[0068] step:

[0069] (1) Design the structure of the airfoil blade according to the requirements of the performance index of the fan for different purposes and the design requirements of the blade mentioned above, and then make the aluminum alloy airfoil blade profile by extrusion method, and the hardness of the profile is controlled between 70-90 degrees between;

[0070] According to the size requirements of the fan blades, cut the profile blanking;

[0071] (2) Use the torsion equipment to process the profile.

[0072] (3) Use cutting equipment to cut and process the root of the profile;

[0073] (4) Setting of impeller connector

[0074] Select a suitable type of stud as the impeller connector, and fix one end of the stud in the positioning hole at the root of the blade;

[...

Embodiment 3

[0080] Embodiment 3: the manufacture of the fan impeller that must be filled when the blade is twisted (the blade cross-sectional structure is as shown in accompanying drawing 3, 4)

[0081] step:

[0082] (1) According to the performance requirements of fans for different purposes and the design requirements of the blades mentioned above, the structure of the airfoil blade is designed, and then the aluminum alloy airfoil blade profile is made by extrusion, and the hardness of the profile is controlled between 70-90 degrees ;

[0083] According to the size requirements of the fan blades, cut the profile blanking;

[0084] (2) Use fine sand or other materials to fill the profile square hole;

[0085] (3) Use the torsion equipment to process the profile;

[0086] (4) Remove powdery filling materials;

[0087] (5) Utilize the cutting equipment to cut and process the blade root;

[0088] (6) Setting of impeller connector

[0089] According to the wind pressure on the blade, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com