Rigid-flexible combined pull rod structure for improving prestress effect of stay cable

A technology of prestressed and cable-stayed cables, which is applied in the direction of cable-stayed bridges, bridge parts, bridge forms, etc., and can solve problems such as inability to overcome the shortcomings of rigid tie rods and not providing them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

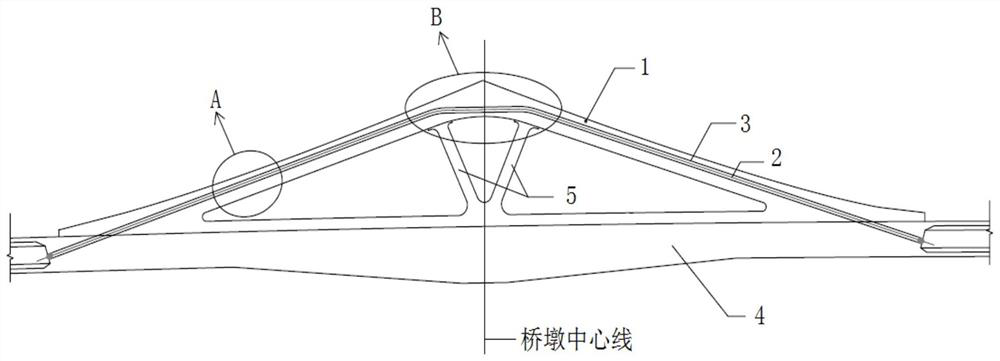

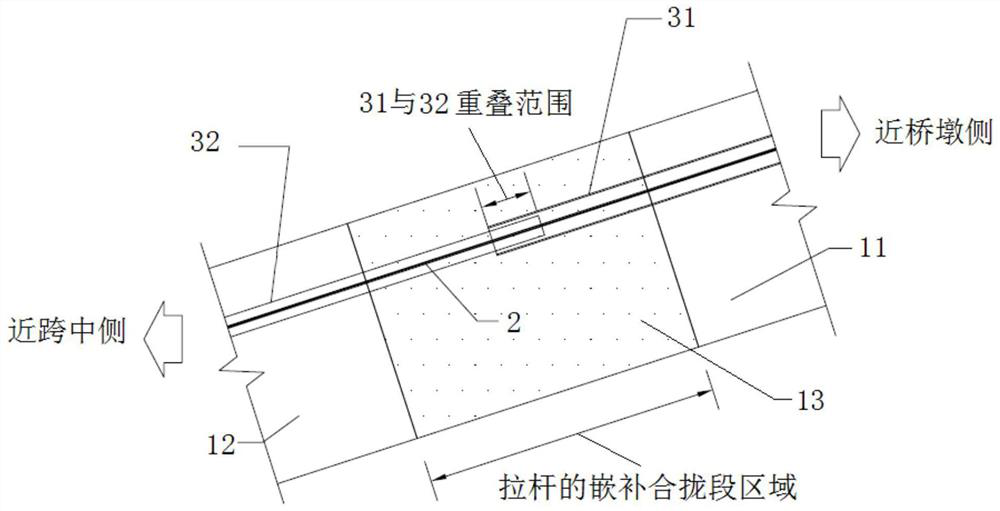

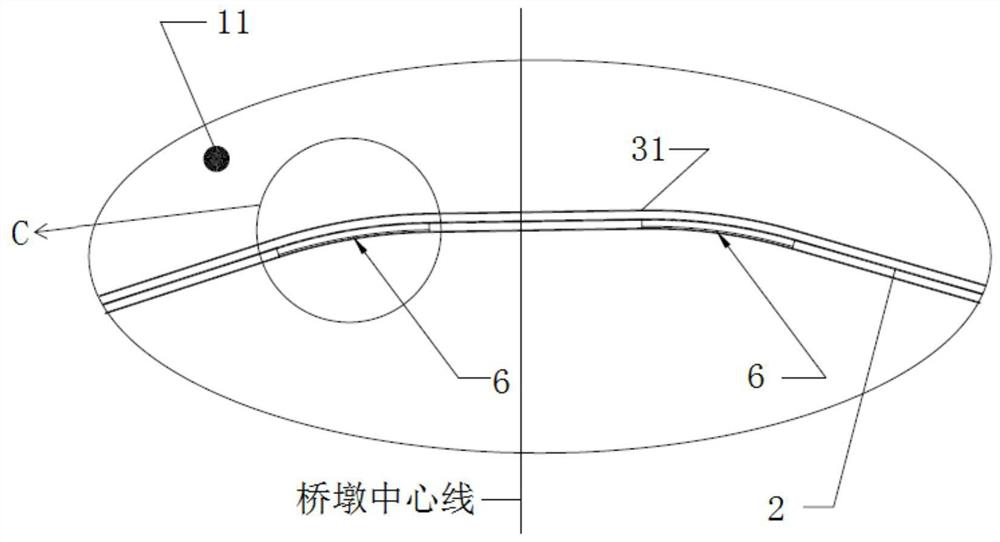

[0049] like Figure 1 to Figure 4 As shown, a specific embodiment of the structure of the rigid-flexible combined tie rod of the present invention at least includes: a tie rod 1 , a stay cable 2 and a stay cable pipe 3 . The cable conduit 3 is located inside the pull rod 1 , and the cable 2 is located inside the cable conduit 3 .

[0050] Tie rod 1 is generally welded and formed by all-steel material, and is a rigid structural member, including the first section 11 fixedly installed with the oblique web bar above the bridge deck, and the second section 12 pre-embedded (or preset) in the box girder 4 of the main bridge , and the interlocking closing section 13 positioned between the first section 11 and the second section 12 when the construction is completed.

[0051] In different embodiments, the cross-sectional shape and size of the tie rod 1 are comprehensively selected according to various factors such as the mechanical performance of the specific structure, architectural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com