Single-box single-chamber box girder and its design method for continuous rigid-frame aqueduct with variable box and variable cross-section

A technology of variable box section, single box single room, applied in bridges, bridge applications, construction, etc., can solve the problems of reducing the position of the core of the section, affecting the durability of the structure, and increasing it, so as to reduce the effect of additional temperature gradient, Enhance the effect of prestressing effect and enhance the waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

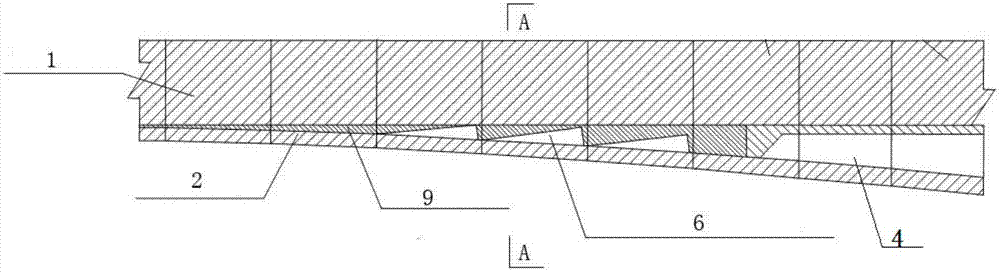

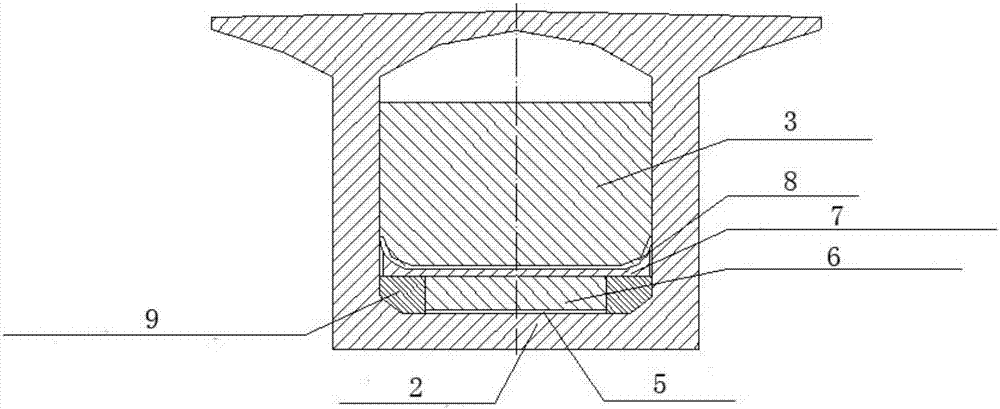

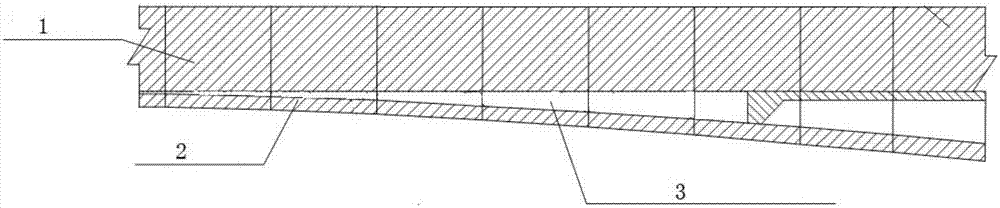

[0016] Embodiment of the present invention: a method for designing a single-box single-chamber box girder of a continuous rigid frame aqueduct with variable cross-section and variable cross-section. In the process of pouring a variable-section single-box single-chamber box girder, the single-box single-chamber box girder follows the section In the process of gradually enlarging, the lower edge of the bottom plate forms an arched curve, and the upper edge of the bottom plate adopts the same change law as the lower edge curve, so that the bottom plate forms an arched curve with the same thickness as a whole (however, in actual construction, if the bridge span is too large In order to meet the design strength, the thickness of the bottom slab should be appropriately increased gradually. However, the curve trend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com